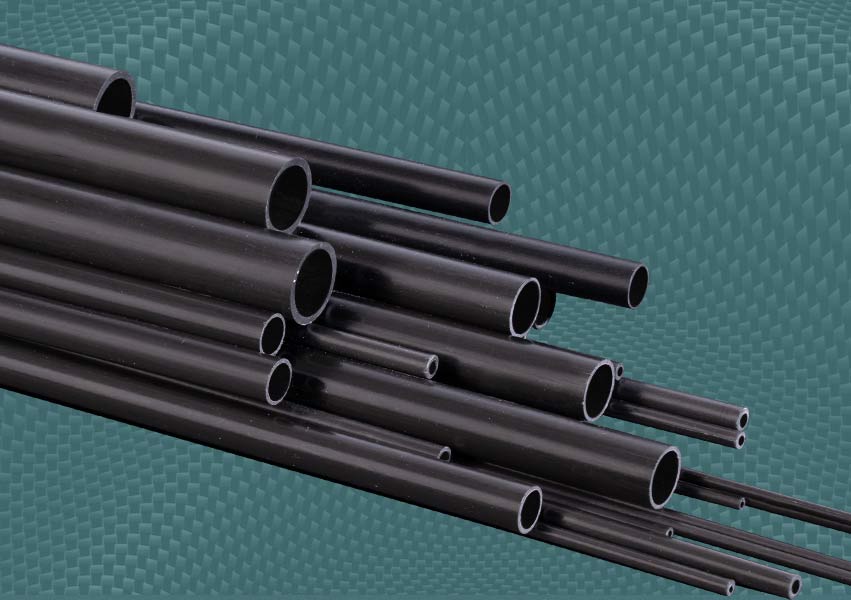

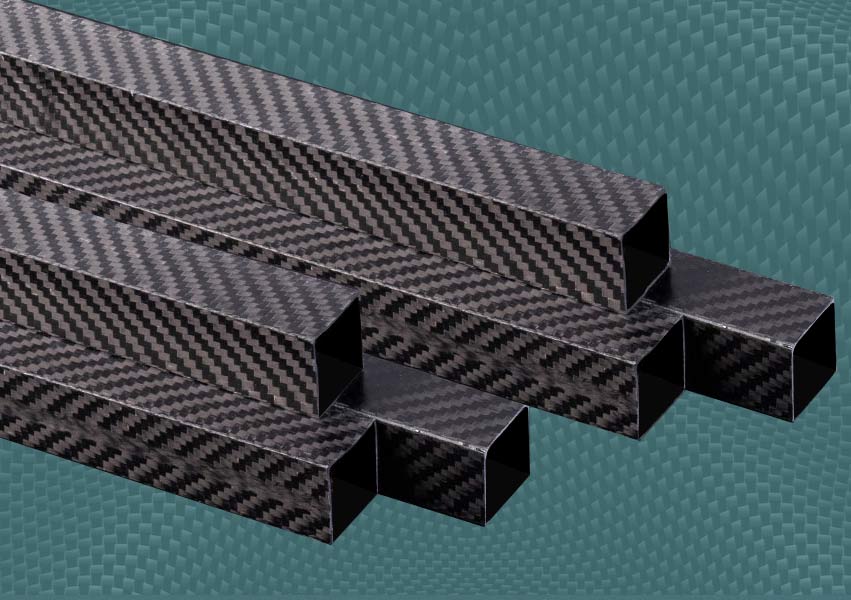

Carbon Fiber Tubes

Carbon fiber tubes are hollow cylindrical structures made primarily from carbon fiber-reinforced polymer (CFRP) composites. They are lightweight, strong, and offer excellent stiffness, making them popular in various industries, including aerospace, automotive, sports equipment, and robotics.

It's worth noting that NitPro Composites carbon fiber tubes are manufactured in two different processes in various dimensions, lengths and thicknesses to suit specific requirements. Both methods of fabricating the tubes offer a combination of high performance, durability and weight, making them a sought-after material in many industries.

Pultruded carbon fiber tubes are manufactured by a highly automated process of continuously pulling carbon fiber composites mixed with resin matrix through heated forming dies. Through this process, continuous length of tubes with constant cross-sections are created in the shape of the die.

Roll-wrapped carbon fiber tubes are produced using multiple wraps of carbon fiber prepregs in many different weave types. Roll wrapping produces multiple surface textures like twill weave, plain weave, etc. with gloss and matte finish

Key Features

- Exceptionally rigid

- High dimensional stability and UV resistant

- High corrosion resistance

- High thermal conductivity in some forms

- Very low thermal expansion (approx. 8 times lower than steel, 11 lower than aluminum)

Carbon Fiber Tube Applications

Carbon fiber tubes can be used in a variety of tubular applications. Here are some examples of current common uses:

- Robotics and automation

- Telescoping poles

- Metrology instrumentation

- Idler rollers

- Drone components

- Telescopes

- Lightweight drums

- Industrial machinery

- Aerospace applications