TECHNOLOGIES

-

Prepreg Tubes

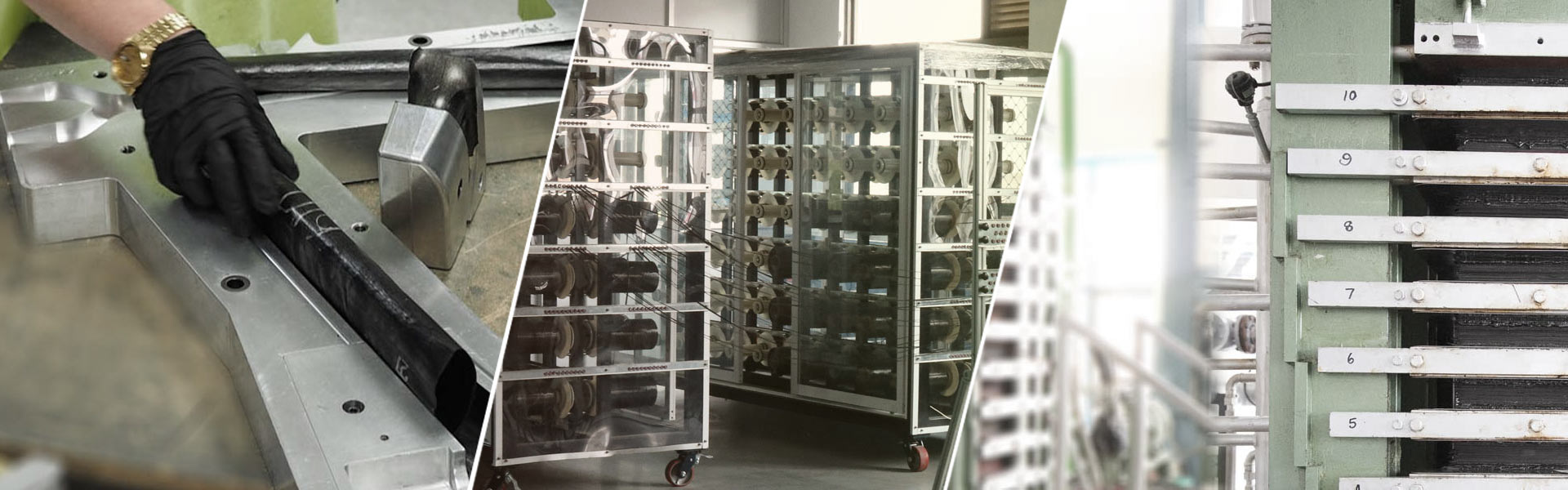

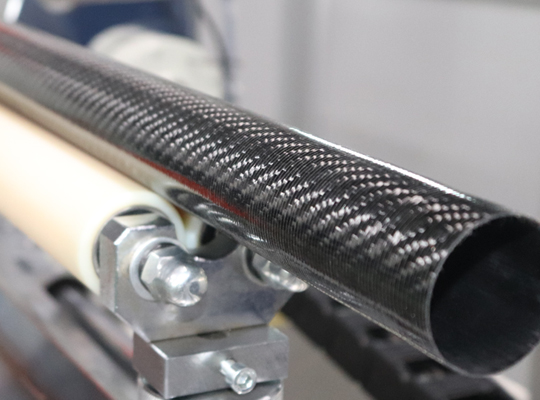

Prepreg TubesNitPro Composites manufactures prepreg carbon fiber tubes using German technology on automatic multi-stage high precision machines. These tubes are made using multiple lay-ups of multi-directional and/or uni-directional prepregs. Prepreg is a composite material made from impregnated fibers with resin known for its high strength-to-weight ratio.

We offer roll wrapped tubes starting from 6 mm to 120 mm diameters in desired wall thickness up to 2 meters in length. The tubes are offered in different finishes like cello-wrapped gloss, smooth grinded gloss, smooth grounded matt in twill, plain weave and unidirectional weave patterns. -

Pultrusion

PultrusionPultrusion is an automated composite synthesis process in which continuous lengths of reinforced polymers with a constant cross-section are produced. During this process, carbon fibers, liquid matrix, and additives are normally pulled through a heated die, converting them into composite products. This process produces high strength to weight ratio part by having high fiber volume fraction.

At NitPro Composites we have a fully automatic digitally controlled Pultrusion machine to produce constant cross-section composite profiles. We have a production capacity of 30000m/month to cater to the global market. For custom profiles, we have the capacity to develop pultrusion molds to produce any constant cross-section composite profile. -

Vacuum Infusion

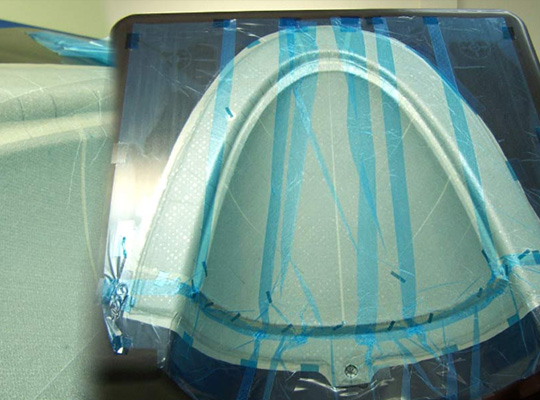

Vacuum InfusionThe Vacuum Infusion Process (VIP) is a method to drive resin matrix into fiber laminate by using vacuum pressure. Dry materials are laid into the mold and the resin matrix is introduced by suction or vacuum creation under a sealed bag.

Vacuum pressure will not allow excess resin matrix that maintain a very good fiber resin ratio in the final product. If in case any excess resin that is introduced will eventually be sucked out into the catch pot. As a result, only the minimum amount of resin is absorbed. This decreases weight, increases strength, and maximizes the properties of fiber and resin. -

Vacuum Bagging

Vacuum BaggingIn a typical hand lay-up process resin content is very high due to manual resin application, vacuum bagging is a technique that reduce resin content. In this process reinforcements are laid into a mold and manually wet out using brushes, rollers, or through other means, now vacuum is applied to bag to suck excess resin out of the laminate. Vacuum bagging greatly improves the fiber-to-resin ratio, and results in a stronger and lighter product.

We at NitPro Composites have facility of Vacuum Bagging with all equipment for Room-Temperature as well as high temperature Applications. We have developed many products as well as prototype with this method. -

Bladder Molding

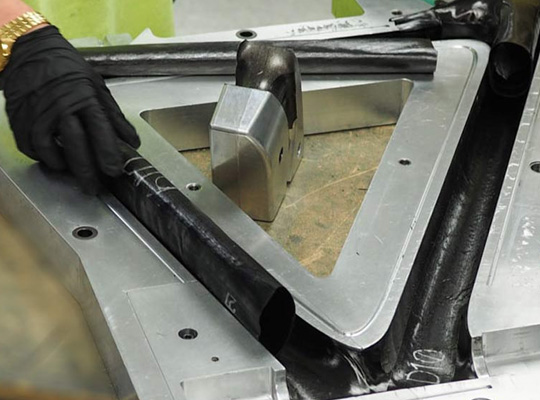

Bladder MoldingFor complex hollow shapes of carbon fiber composites, bladder molding is the ideal process. Composite material is applied to a bladder and the part is inserted into a female cavity mold. A press is used to clamp the mold shut and heat is applied to cure the part. Air pressure is used to force the laminate outward in the cavity, consolidating the material in the closed mold. The bladder is removed after cure and your end product is a light, strong hollow structure. Bladder molding has enabled composite manufacturing to strengthen components with carbon fibers. Aerospace, defense, automotive, medical and sports and recreation have all found ways to improve their respective industries.

NitPro Composites has the capability and hands on experience of manufacturing many intricate bladder molding projects. Here we develop many products with this technology like carbon fiber badminton rackets. -

Compression Molding

Compression MoldingThe process involves the placement of the input material (prepregs) into a heated mold, where the material gets cured under the action of temperature and pressure.

This process is used for high volume production. Carbon/Epoxy prepregs are be processed in a closed mold under high pressure, and temperature. It reduce the curing cycle. A cured composite product can be obtained in a time ranging from less than 2 to 10 minutes, it depends on the part thickness. The process simply involves the introduction of the input material within a heated mold, where the material cures under the action of temperature and pressure. -

Weaving

WeavingCarbon fiber weaving technology represents a cutting-edge method in fabric production. Our weaving process intricately interlaces carbon fibers, ensuring high-performance materials with exceptional strength and lightness. Using state-of-the-art looms, we meticulously control each weaving step, guaranteeing uniform tension and alignment, resulting in fabrics ideal for aerospace, automotive, and sporting applications. Our commitment to innovation drives the continual enhancement of these weaving technologies, delivering superior, durable carbon fiber materials that meet industry demands for reliability and performance.

-

Tool Room including CNC

Tool Room including CNCOur Tool Room, equipped with advanced CNC (Computer Numerical Control) technology, delivers precision and versatility in manufacturing. The integration of CNC machinery enables the creation and modification of intricate tooling components with exceptional accuracy. Our skilled technicians leverage this technology to craft custom-designed parts and molds, ensuring precise output. From prototyping to complex component production, our CNC-driven Tool Room guarantees high-quality, tailored solutions that meet rigorous industry standards efficiently and effectively.

-

Product Designing

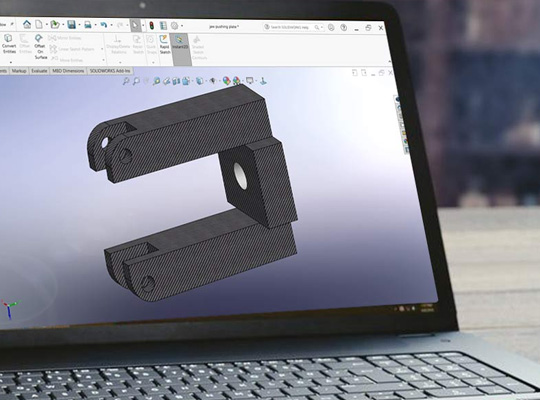

Product DesigningProduct design & tool development uses the advanced computer-aided system to design and develop new products from scratch. We use 3D CAD software to develop mold and tools for composite products.

NitPro Composites offers engineering solutions for its customers in composites ranging from concept design, structural design, engineering design & design validation. Our team of design & structural engineers using modeling software like Solid Works ensure the product is not only aesthetically designed but suits structurally for the end-use.