Selecting the Right Carbon Fiber Sheet for Your Project

👁 Reads: 141

Carbon fiber sheets are widely recognized for their strength, lightweight properties, and versatility, making them ideal for a wide range of projects, from automotive and aerospace to sporting goods and consumer electronics. With various types and grades available, selecting the right carbon fiber sheet for your project is essential to ensure optimal performance, durability, and efficiency. Understanding the properties of carbon fiber sheets and how they compare to other carbon fiber products, such as carbon fiber rods, tubes, and plates, can help you make the best choice.

Why Choose Carbon Fiber Sheets?

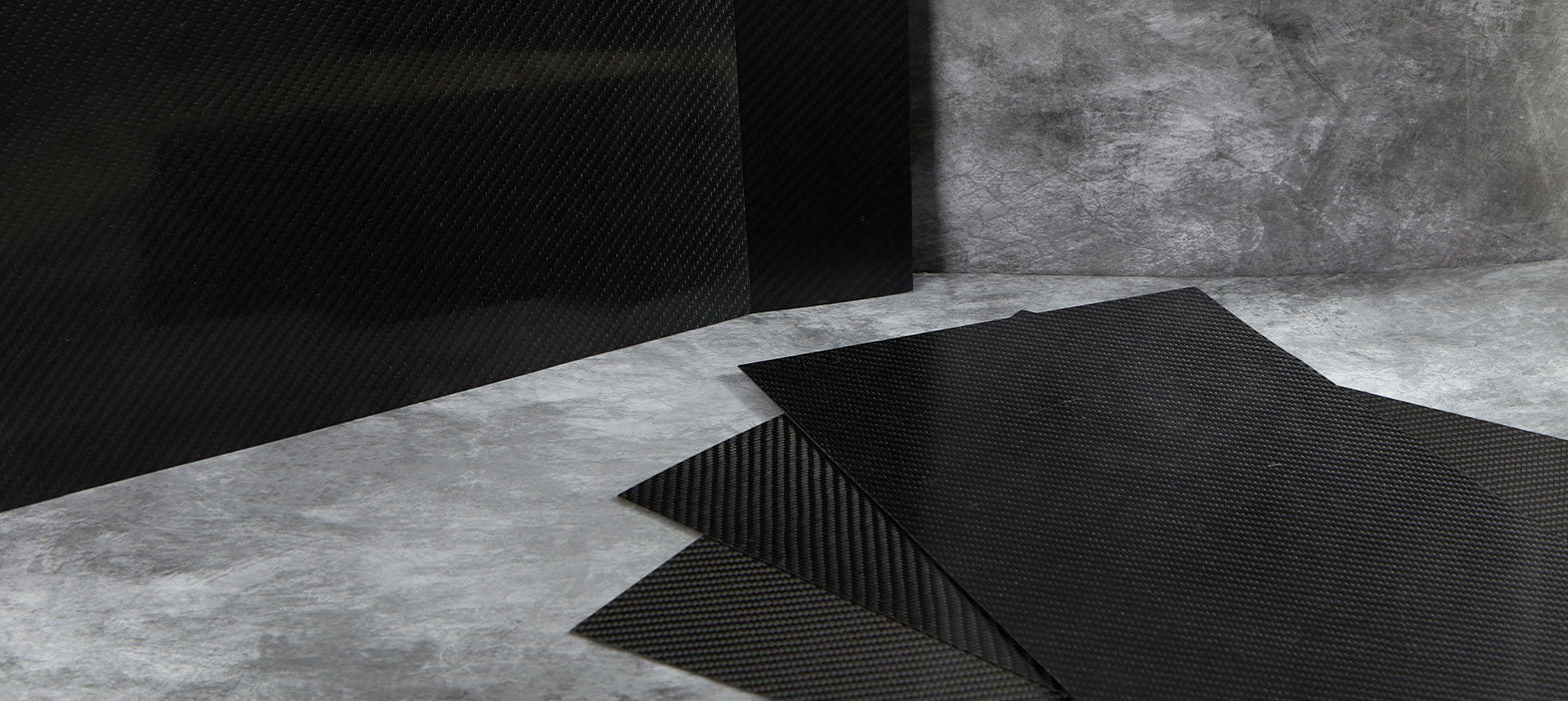

Carbon fiber sheets are crafted from multiple layers of woven carbon fibers, bonded with resin to create a durable, lightweight panel. The unique properties of carbon fiber make these sheets resistant to bending, warping, and extreme environmental conditions, making them ideal for projects that require both strength and aesthetic appeal. Compared to traditional materials like steel or aluminum, carbon fiber sheets offer a superior strength-to-weight ratio, reducing overall weight while maintaining structural integrity.

Types of Carbon Fiber Sheets

Before selecting a carbon fiber sheet, it’s important to understand the different types available and their specific benefits:

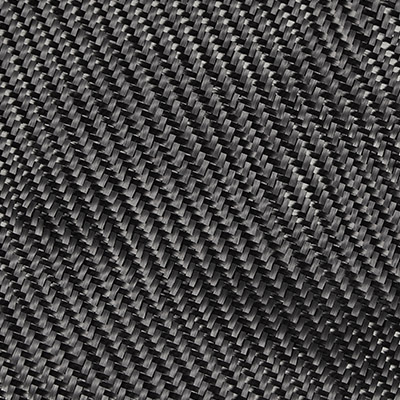

- Plain Weave Sheets: These sheets have a basic, checkerboard appearance with evenly woven fibers, offering moderate strength and flexibility. Plain weave carbon fiber sheets are popular for decorative applications or projects requiring a sleek finish.

- Twill Weave Sheets: Twill weave sheets have a diagonal pattern, providing higher strength and flexibility than plain weave options. Their sophisticated look makes them suitable for automotive, consumer electronics, and sports equipment.

- Unidirectional Sheets: In unidirectional sheets, all fibers run in one direction, giving them exceptional strength in a specific direction. These sheets are ideal for structural applications that require maximum strength along a particular axis.

- Quasi-Isotropic Sheets: Quasi-isotropic sheets feature layers of fibers oriented in different directions, providing balanced strength across all axes. These sheets are perfect for projects that need a uniform distribution of strength and stiffness.

How to Select the Right Carbon Fiber Sheet

- Project Requirements: Start by assessing the strength, flexibility, and durability requirements of your project. If the sheet will be used in a high-stress application, such as a structural component in an automotive or aerospace project, choose a carbon fiber sheet with a high tensile strength, like twill weave or quasi-isotropic sheets. For decorative purposes, a plain weave sheet will work well.

- Consider Other Carbon Fiber Products: For projects requiring more rigidity or unique shapes, consider combining carbon fiber sheets with other carbon fiber products, like carbon fiber rods and tubes. Carbon fiber rods, for example, are excellent for reinforcing structures, while carbon fiber tubes offer a lightweight, tubular alternative for frames or support beams.

- Thickness: The thickness of the carbon fiber sheet impacts its strength, flexibility, and weight. Thicker sheets provide more durability but can add unnecessary weight if not required. For lightweight projects, a thinner carbon fiber sheet may be sufficient, but ensure it meets the necessary strength standards for your application.

- Finishing Options: Carbon fiber sheets come with various finishing options, including gloss, matte, and textured finishes. If appearance is essential, choose a finish that complements the aesthetic of your project. Glossy carbon fiber plates, for instance, add a high-tech look and are ideal for consumer products and electronics, while matte finishes are better suited for applications requiring a more subtle look.

- Temperature and Environmental Factors: Some projects, particularly those in automotive or aerospace applications, may involve exposure to extreme temperatures or harsh environmental conditions. Ensure the carbon fiber sheet you choose is rated for the temperature range and environment in which it will be used.

Benefits of Using Carbon Fiber Sheets Alongside Other Carbon Fiber Products

In some projects, using carbon fiber sheets in combination with other carbon fiber components, such as carbon fiber rods, carbon fiber plates, and carbon fiber tubes, can offer a comprehensive solution for enhanced durability and stability. For example, carbon fiber rods can reinforce frames created with carbon fiber sheets, and carbon fiber tubes can provide additional support and reduce flex in structural applications. By leveraging a combination of carbon fiber products, you can achieve a balance of strength, weight, and performance that’s optimized for your project’s specific needs.

Selecting the right carbon fiber sheet for your project is essential to achieving the best results in terms of performance, durability, and weight reduction. Whether you’re working on a high-performance car, a piece of sporting equipment, or a consumer product, understanding the different types of carbon fiber sheets, their benefits, and how they work alongside other carbon fiber products like rods, plates, and tubes can make all the difference. By choosing the right carbon fiber sheet, you’ll be able to create products that are not only functional but also embody the cutting-edge aesthetics and strength for which carbon fiber is celebrated.