Use of Carbon Fiber Sheets in Sports Equipment Manufacturing

👁 Reads: 607

The sporting world is ever-evolving. New records are set, boundaries are pushed, and athletes continually seek the next innovation that will give them a competitive edge. At the heart of this relentless pursuit of excellence lies technology, and more specifically, the materials used to craft high-end sporting equipment. One material that has been making waves in this arena is carbon fiber sheets. The carbon fiber composite is used in the field of sports equipment manufacturing extensively for the wide range of competitive sport needs.

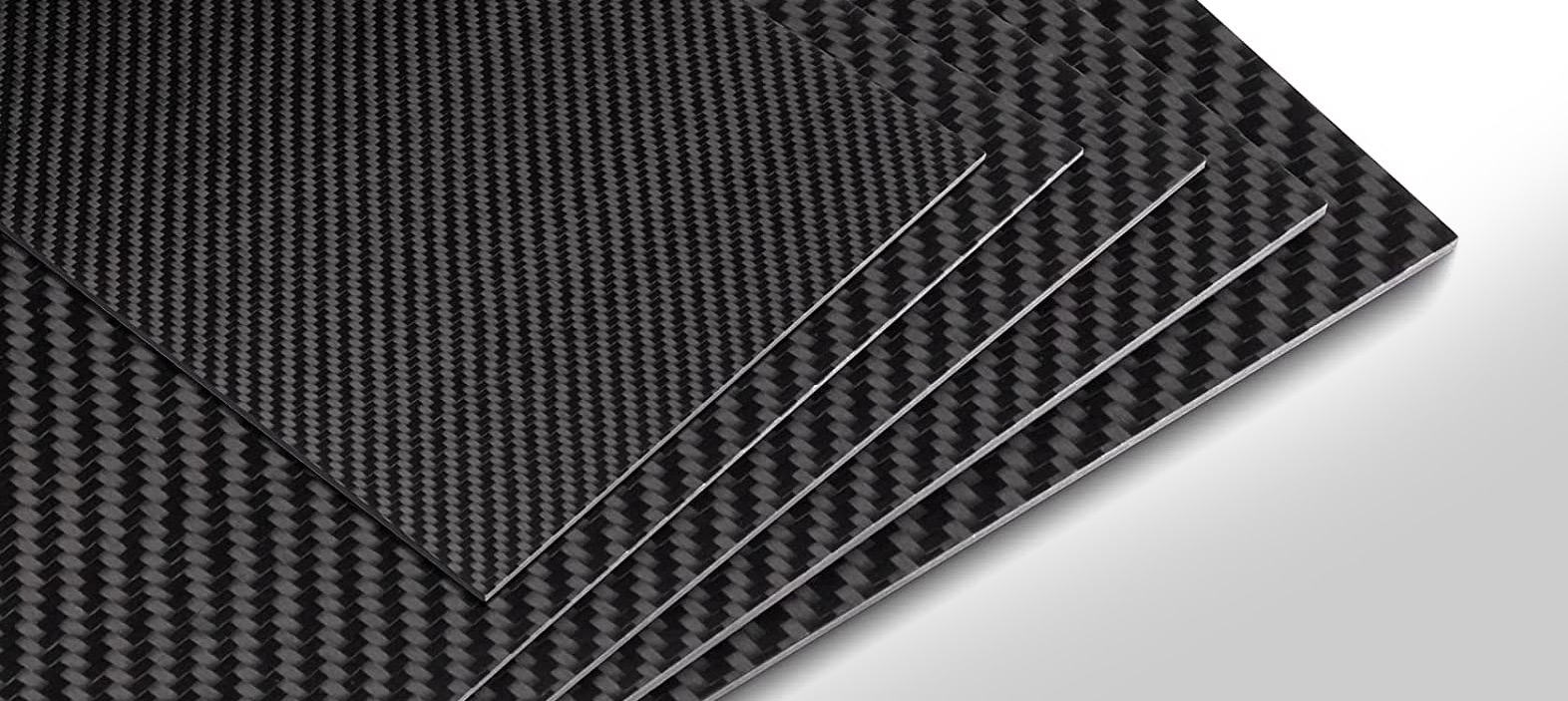

What are Carbon Fiber Sheets?

Carbon fiber sheets, derived from carbon atoms, are renowned for their lightweight properties and incredible strength. Their impressive strength-to-weight ratio has made them a preferred choice in various industries. In the world of sports, where every ounce can make a difference, the use of carbon fiber sheets has proven transformative. Its corrosion-resistant and durable properties set it apart in the use of high chances of wear and tear. Fromm bicycle parts to rackets, clubs to sticks, the material significantly reduces weight without compromising on the strength factor allowing the user or athlete outstanding performance in various sports.

Why the Use of Carbon Fiber in Sports

The core advantage of carbon fiber lies in its unique structure. The composite fibers are bonded together in a crystalline arrangement, providing unmatched stiffness and strength. When crafted into sheets or other forms of carbon fiber products, they bring this inherent strength to the final product, without adding significant weight.

Applications in Sports Equipment

- Tennis Rackets: Gone are the days when wooden rackets ruled the tennis courts. Modern tennis rackets, designed for maximum power and precision, leverage the benefits of carbon fiber composites. A carbon fiber provides the stiffness required to increase power while ensuring the racket remains lightweight for agility. Even in the case of frequent use, it is durable and corrosion resistant.

- Golf Clubs: The shaft of many modern golf clubs incorporates carbon fiber to reduce the overall weight. This allows players to achieve faster swing speeds and, therefore, greater distances. Also, the hot and humid environment of golf courses do not have much impact on the material. It does not rust and can be efficiently managed with minimal efforts.

- Bicycles: Professional cycling demands equipment that is both light and durable. Carbon fiber is used to craft frames that are incredibly light, allowing cyclists to achieve greater speeds. Moreover, the strength of the composite material ensures these bikes can withstand the rigors of professional racing.

- Skis and Snowboards: Carbon fiber sheets add stiffness to skis and snowboards, improving their responsiveness. They also reduce weight, allowing for quicker turns and better overall control.

- Hockey Sticks: Carbon fiber composites provide the necessary flexibility and strength that modern hockey demands, allowing for powerful shots and passes.

Advantages over Traditional Materials

Traditionally, metals like steel and aluminum or woods were used in sports equipment manufacturing. While they had their merits, they could not match the versatility of carbon fiber. The main advantages include:

- Weight Reduction: Equipment made using carbon fiber is significantly lighter, which can be a game-changer in many sports.

- Increased Durability: Carbon fiber products resist wear and tear better than many traditional materials, ensuring longevity.

- Flexibility in Design: Carbon fiber can be molded into various shapes and sizes, enabling more ergonomic and efficient designs.

Disadvantages compared with Traditional Materials

Once we look at the merits it is also important to look at the demerits. While the advantages certainly weigh over the negatives, the use of carbon fiber sheets in sports equipment manufacturing has drawbacks that are:

Expensive: The cost factor of manufacturing carbon fiber products is fairly hefty. The composite material undergoes a complete process of compression molding or vacuum infusion according to the manufacturers and the end use of the sheet.

Recycling Challenges: The composite material certainly has a few recycling challenges. It is expensive and has environmental impact if not done properly.

Another key factor is manufacturing challenges but an experienced carbon fiber manufacture can tackle challenges and deliver a supreme quality that can be used without any hassle in various industrial applications.

Looking Ahead

As technology continues to advance, we can expect even more innovative uses of carbon fiber products in sports equipment manufacturing. As athletes push their limits, the tools they use must evolve in tandem. Carbon fiber products, with their unique blend of strength and lightness, are set to be at the forefront of this evolution.

In conclusion, the sporting world's adoption of carbon fiber sheets is a testament to their unparalleled advantages. Whether you're a professional athlete or a weekend warrior, the benefits of using equipment made from carbon fiber composites are undeniable. You can explore the various products such as badminton or tennis rackets, bicycles, golf clubs and hockey sticks, skis and snowboards for all sporting needs. NitPro Composites are reputed carbon fiber manufactures that have been delivering carbon fiber products including sheets, rods, tubes and CNC profiles of uncompromising quality.