Can Carbon Fiber Be Repaired? Myths vs. Reality

👁 Reads: 380

Carbon fiber composites are powering industries like automotive, aerospace, marine, medical and sports equipment with their incredible low weight, high strength and durability. However, there are times when damage occurs, which brings uncertainty: Can carbon fiber be repaired effectively, or does it always require complete replacement? This comprehensive guide separates common myths from reality to help you make informed decisions about your carbon fiber components.

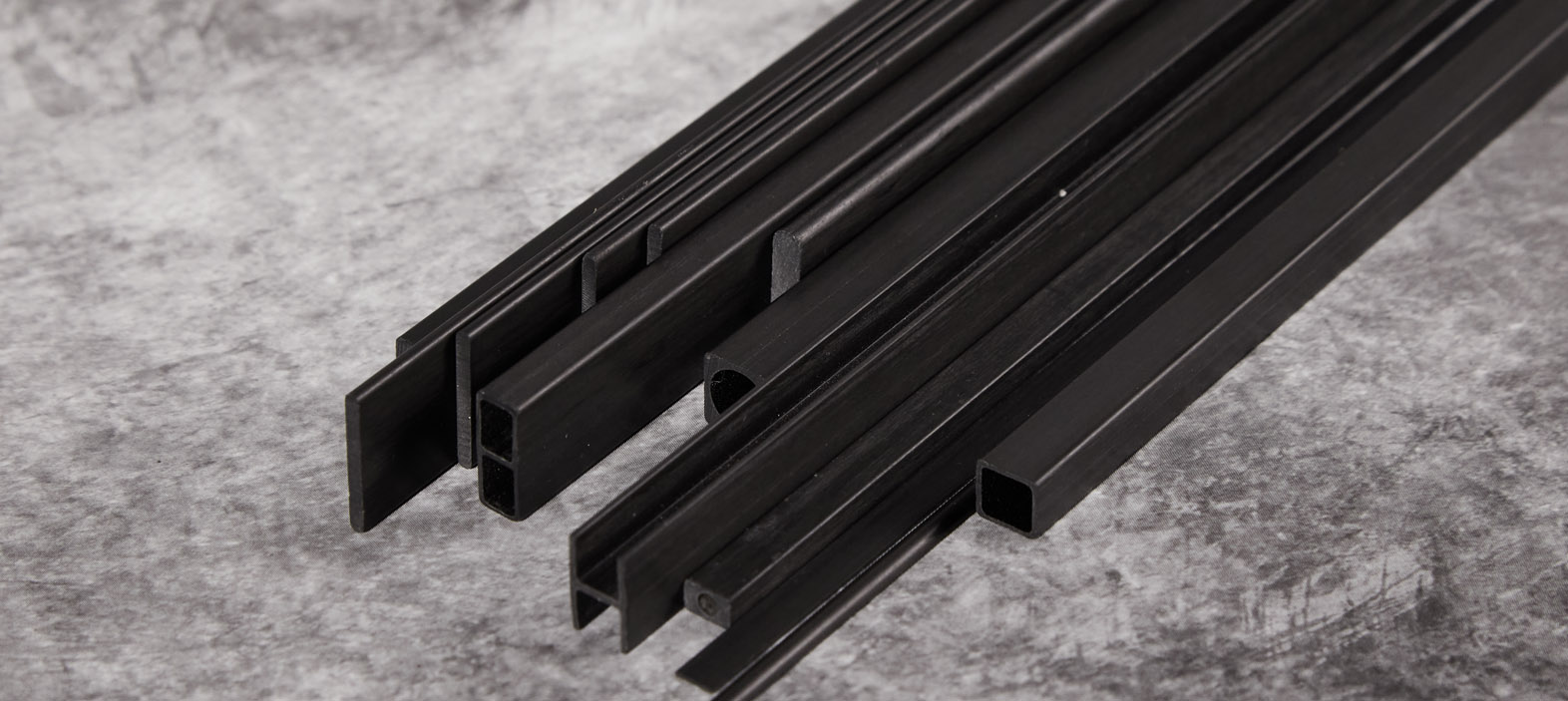

Before diving into repairs, it's essential to understand what carbon fiber actually is. Carbon fiber composites consist of:

- Carbon Fiber Strands: Thin filaments (5-10 micrometers in diameter) made of carbon atoms

- Resin Matrix: Typically epoxy that binds the carbon fibers together

- Layering Structure: Multiple layers of carbon fiber sheets arranged in specific orientations for optimal strength

This composition gives carbon fiber its remarkable properties but also influences how it can be repaired when damaged.

Understanding repairs for carbon fiber can be understood clearly once you understand the types of damage.

Common Types of Carbon Fiber Damage

Different types of damage require different repair approaches:

- Surface Scratches with visible minor damage to the clear coat or top resin layer

- Delamination and separation between carbon fiber layers

- Cracks and fractures in the material that may extend through multiple layers

- Punctures and complete penetration through the carbon fiber structure

- Stress fractures and hairline cracks that develop over time from repeated stress

Myth #1: Repaired Carbon Fiber Is Weaker Than the Original

Reality: When properly repaired using high-quality materials and methods, carbon fiber can regain most of its original strength and durability. Structural repairs mostly involve layering new carbon fiber products with resins, ensuring proper bonding and alignment to maintain longevity. However, poor-quality repairs or the wrong fiber approach can compromise strength and resilience.

Myth #2: Carbon Fiber Cannot Be Repaired

Reality: Contrary to popular belief, carbon fiber can be repaired efficiently. The key lies in the level and type of damage. Minor damage, crack and surface scratches can easily be fixed using epoxy resins, however, big or deeper structural damage require professional composite repair techniques, such as resin infusion repair, lay-up reinforcement and vacuum bagging.

Myth #3: Carbon Fiber Repairs are as Good as Professional Repairs

Reality: While minor cosmetic fixes can be handled with Do-It-Yourself (DIY) kits but structural repairs or repair of more intricate parts require professional expertise. Professionals use advanced techniques like wet lay-up repair, autoclaving, vacuum-assisted resin infusion, and high-temperature curing to ensure a strong, lasting repair.

Myth #4: Any Carbon Fiber Damage Requires Full Replacement

Reality: While critical failures or damage (like shattering or delamination over a large area) may require replacement, many forms of damage, such as small cracks, matrix cracking, or localized delamination, can be repaired. Professional assessment is important to determine if the repair is reversible.

Myth #5: Composites Are Difficult to Work With

The Truth: New advancements are making composite installation, repairs, and manufacturing easier than ever

While some early composites required specialized handling, today’s technological advancements have made them easier to install and maintain.

Rapid Curing Technologies: High-Tg composites cure at room temperature, eliminating the need for expensive and slow oven curing.

Field-Ready Solutions: Composite wraps for pipeline repair and structural reinforcement reduce downtime and offer easy application for on-site crews.

Innovative Manufacturing Processes: Automated production techniques have made composite manufacturing faster, more precise, and more scalable than ever before.

From construction to aerospace, composites are now more accessible and user-friendly, making them a preferred choice for engineers and manufacturers worldwide.

While early composites required specialized handling, today's technological advancements have made them easier to install and maintain:

The Carbon Fiber Repair Process: What to Expect

A professional carbon fiber repair typically follows these steps:

- Assessment: Evaluation of damage extent and structural impact

- Preparation: Cleaning and preparing the damaged area

- Material Removal: Carefully removing damaged sections

- Fiber Layup: Applying new carbon fiber material in the correct orientation

- Resin Application: Infusing or applying appropriate resin systems

- Curing: Using heat or ambient conditions to properly cure the repair

- Finishing: Sanding, clear coating, and polishing to match original appearance

- Testing: Verifying structural integrity through appropriate tests

When Should Carbon Fiber Be Repaired vs. Replaced?

Repairable:

- Small cracks or chips in non-load-bearing areas

- Superficial scratches and clear coat damage

- Minor delamination in non-critical sections

Replacement Needed:

- Damage in high-stress areas (e.g., load-bearing sections of a bicycle frame or aircraft component)

- Large-scale structural failure, shattered fibers or crippling failures

- Deep delamination (if the cracking leads to separation between layers) affecting core strength

- Epoxy cracking (if the resin used is epoxy)

When deciding between repair and replacement, consider Repair Costs vs Replacement Costs. sometimes repairs can cost almost the original value so consider the replacement cost.

Environmental Benefits of Repairing Carbon Fiber

Choosing to repair rather than replace carbon fiber components offers significant environmental advantages:

- Reduced Carbon Footprint as manufacturing new carbon fiber produces 14-25 kg CO₂ per kg of material

- Resource Conservation as repairs extend product lifecycles and reduce raw material consumption

- Waste Reduction as carbon fiber is challenging to recycle, making repair a more sustainable option

Future of Carbon Fiber Repair Technologies

The field of carbon fiber repair continues to evolve with promising developments:

- Self-healing Composites with embedded microcapsules that release resin when damaged

- 3D-Printed Repair Patches, custom-fabricated repair materials that perfectly match the damaged area

- Nanomaterial Reinforcements that enhance repair strength

- UV-Cured Repair Systems that reduce repair time and improve field applications

Final Thoughts

Carbon fiber repairs are possible and, when done correctly, can restore similar strength and functionality. However, not all damage is repairable, and expert assessment is crucial to determine the best course of action. Understanding the realities of carbon fiber repair helps in making informed decisions rather than relying on myths.