Why RC Enthusiasts Are Switching to Carbon Fiber Chassis – Performance Gains Explained

👁 Reads: 110

In the high-speed world of RC racing and drone performance, every gram and every millisecond counts. Whether you're an RC car hobbyist, a drone racer, or a composite engineer pushing the limits of materials science, one trend is impossible to ignore—the rapid adoption of carbon fiber RC chassis. What started as a niche upgrade for elite competitors has quickly become a must-have for serious RC enthusiasts. But what exactly makes carbon fiber such a game-changer?

In this blog, we'll explore why RC enthusiasts are switching to carbon fiber chassis, dig into the real performance gains, and offer insights into how this material is transforming the future of RC vehicles.

Why Chassis Material Matters in RC Racing

The chassis is the backbone of any RC model. It supports the weight, withstands impacts, absorbs vibrations, and connects all critical components—from the suspension and drivetrain to the battery and electronics.

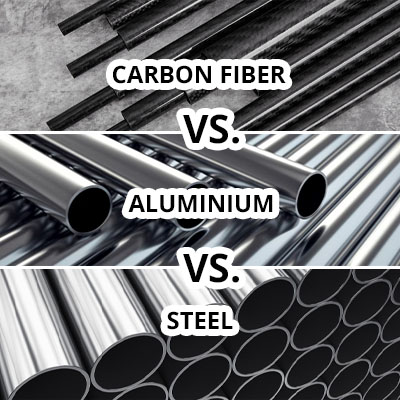

A chassis must balance strength, weight, and flexibility, especially in competitive RC racing or aerobatic drone movements. The old materials like plastic, aluminium, or even steel serve well in basic applications, but their performance is relatively low. That’s where carbon fiber RC chassis enters the spotlight.

Benefits of Carbon Fiber in RC Models

1. Lightweight for Maximum Speed

Carbon fiber is renowned for its high strength-to-weight ratio. It can be up to 5 times stronger than steel and 2 times stiffer than aluminium, while weighing significantly less. A lighter RC car frame means faster acceleration, improved agility, and reduced energy consumption—critical advantages in both racing and aerial applications.

2. Exceptional Rigidity and Handling

Rigidity equals better handling. Carbon fiber doesn’t flex like plastic or bend like aluminium under stress. That stiffness directly translates into more precise cornering, reduced chassis twist, and better control during high-speed operations. For drone racers, this means sharper turns and smoother responsiveness in flight.

3. Heat and Vibration Resistance

Carbon fiber dissipates heat better than plastics and resists warping under high temperatures, which helps when motors and batteries heat up. Additionally, it absorbs vibrations more effectively, reducing stress on sensitive electronics and improving overall stability.

The Comparisons: Carbon Fiber vs Plastic vs Aluminium

Property |

Plastic Chassis |

Aluminium Chassis |

Carbon Fiber Chassis |

Weight |

Light, but weak |

Heavier |

Ultralight |

Strength |

Low |

Moderate |

High |

Rigidity |

Poor |

Good |

Excellent |

Heat Resistance |

Low |

Good |

Excellent |

Durability |

Prone to cracks |

Can dent or bend |

Very resilient |

Cost |

Low |

Moderate |

Higher |

While plastic is inexpensive and aluminium offers some improvement, carbon fiber offers the best all-around performance, especially for enthusiasts serious about speed and precision.

What RC Communities Are Saying

Across forums, race tracks, and drone racing events, users are reporting noticeable improvements after switching to carbon fiber chassis:

- RC car racers mention cutting down lap times by over a second due to lighter weight and increased cornering stability.

- FPV drone pilots praise the rigid airframes for maintaining tuning consistency and reducing oscillations in aggressive flight conditions.

- Bashers and hobbyists note longer part life and fewer breakages during crashes compared to plastic frames.

On platforms like Reddit, RC Groups, and YouTube, content creators regularly show side-by-side comparisons and performance gains that make a compelling case for investing in a carbon fiber RC chassis.

Maintenance Tips for Carbon Fiber RC Parts

To get the most out of your carbon fiber upgrades, here are some quick care tips:

- Avoid over-tightening screws. Use washers and proper mounting hardware to prevent delamination.

- Clean regularly. Dust and grit can wear down the glossy finish—wipe down with a microfiber cloth.

- Inspect for cracks. While rare, high-impact crashes can cause invisible micro-cracks. Check after heavy use.

- Protect edges. Edge fraying can be prevented by sealing with epoxy or CA glue if needed.

With proper care, carbon fiber components will last significantly longer than plastic or aluminium counterparts.

Conclusion: Why the Switch Is Worth It

The shift toward carbon fiber RC chassis is not just a trend; it’s a reflection of evolving performance demands in the RC and drone world. From increased durability and precision to lighter builds that leave competitors in the dust, the benefits of carbon fiber in RC models are too compelling to ignore.

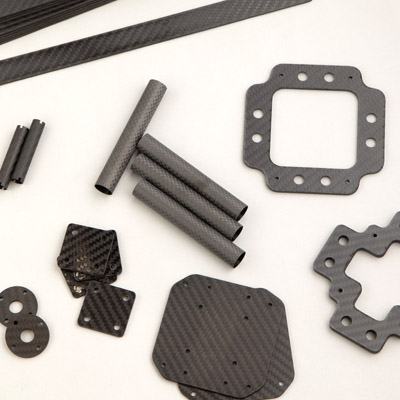

Whether you're an aftermarket retailer, drone manufacturer, or just looking to dominate your next race day, upgrading your RC car or drone with carbon fiber parts is a proven way to take your setup to the next level.

Ready to Upgrade?

At NitPro Composites, we specialize in precision-engineered carbon fiber components designed for RC enthusiasts, racers, and professionals alike. Browse our selection of carbon fiber RC upgrades, or get in touch for custom solutions tailored to your needs.