Innovations in Carbon Fiber Reinforcement: Shaping the Future of Lightweight Manufacturing

👁 Reads: 955

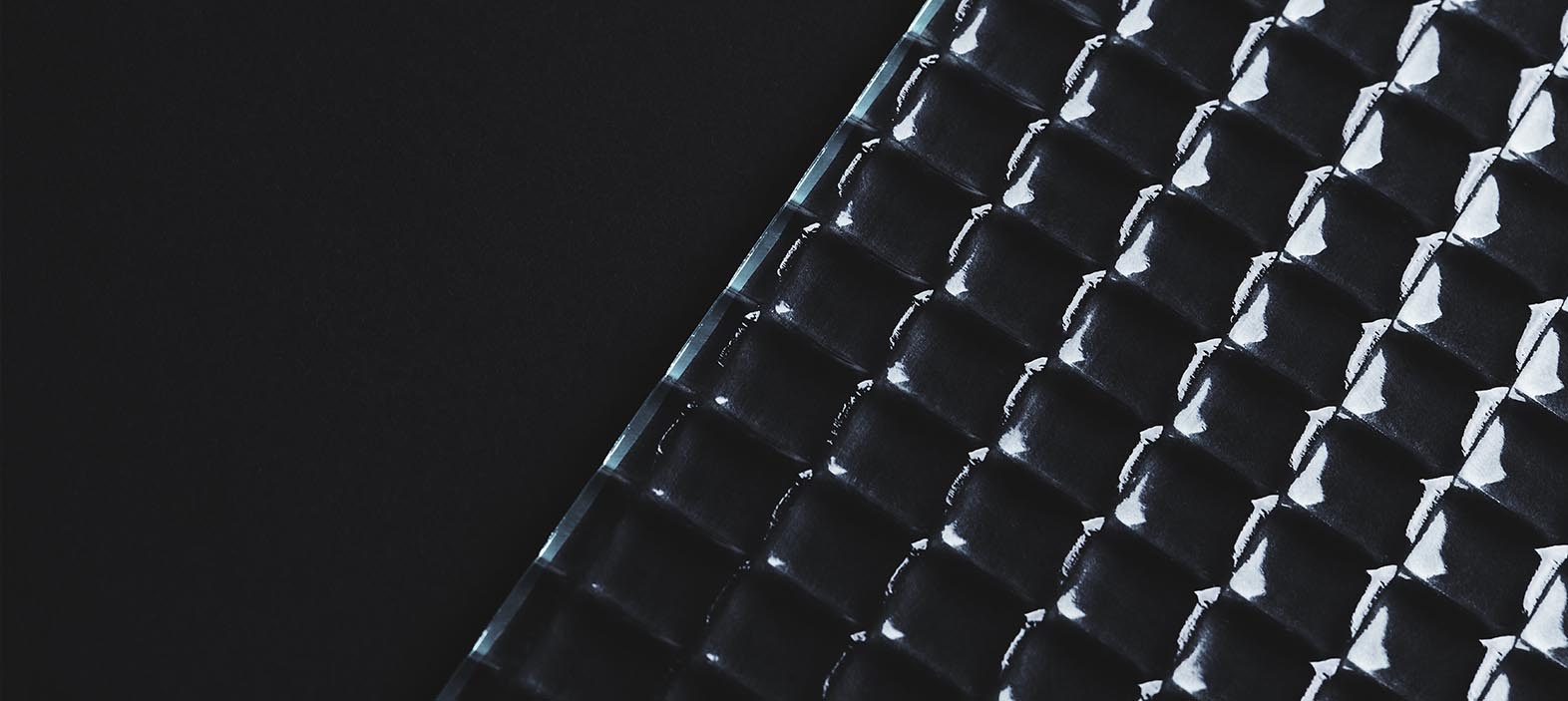

In today’s rapidly evolving industrial landscape, the demand for lightweight materials is growing more than ever. Industries ranging from aerospace to automotive are constantly seeking ways to enhance performance while reducing weight. One of the most significant advancements in this quest is carbon fiber reinforcement, a game-changing innovation that is revolutionizing the world of lightweight materials and advanced composites.

What is Carbon Fiber Reinforcement?

At its core, carbon fiber reinforcement refers to the integration of carbon fibers into a material, typically a polymer, to create a composite with superior strength, stiffness, and lightweight characteristics. Carbon fibers themselves are incredibly thin—about one-tenth the diameter of a human hair—but their strength-to-weight ratio is unmatched. When woven into fabrics or integrated into matrix materials, they form advanced composites that can be used in a wide range of applications.

Carbon fiber composites are known for their exceptional strength, durability, and lightness, making them ideal for industries where weight reduction is critical without compromising structural integrity. Over the years, the application of carbon fiber has expanded exponentially, particularly in sectors such as aerospace and automotive manufacturing.

The Role of Carbon Fiber in Aerospace Composites

The aerospace industry has long been a pioneer in the use of carbon fiber reinforcement. Airplanes, spacecraft, and drones rely on lightweight materials to improve fuel efficiency, range, and overall performance. Carbon fiber's ability to withstand extreme conditions, such as high stress and temperatures, makes it indispensable in this field.

One of the most well-known uses of aerospace composites is in aircraft design. Airplane manufacturers like Boeing and Airbus use carbon fiber composites in the construction of fuselages, wings, and tail structures, reducing the overall weight of their aircraft while maintaining superior safety and performance standards. The carbon fiber applications in this industry help airlines reduce fuel consumption, which is a win for both economics and sustainability.

For example, the Boeing 787 Dreamliner is composed of nearly 50% composite materials, including carbon fiber, which allows it to be lighter and more fuel-efficient compared to traditional aircraft. The reduction in weight translates to lower emissions, making carbon fiber a key player in the future of green aviation.

Carbon Fiber in Automotive: A Drive Toward Efficiency

The automotive industry is another major benefactor of carbon fiber technology. As governments and consumers push for more environmentally friendly vehicles, the need to improve fuel efficiency and reduce emissions is paramount. One way automakers are achieving this is through the use of carbon fiber in automotive applications.

Carbon fiber composites are now being used in the production of high-performance cars, electric vehicles, and even mainstream automobiles. Components such as hoods, body panels, and chassis parts are being replaced with carbon fiber materials to significantly reduce vehicle weight without compromising safety or performance.

One of the earliest adopters of carbon fiber in the automotive world was luxury sports car brands like Ferrari and Lamborghini. Their high-performance vehicles need to be light and fast, and carbon fiber allows them to achieve this without sacrificing structural integrity. However, as the cost of carbon fiber production decreases, we are starting to see more mainstream automakers incorporating advanced composites into their models.

Tesla, for example, uses carbon fiber in the production of its electric vehicles to enhance range and performance. By reducing the weight of the car, they are able to maximize battery efficiency, giving drivers longer ranges on a single charge. This trend will likely continue as the automotive industry moves toward electrification and more sustainable vehicle production.

Innovations Driving the Future of Carbon Fiber Reinforcement

The future of carbon fiber reinforcement looks incredibly promising as new innovations continue to emerge. Research and development efforts are focused on improving the production processes of carbon fiber to make it more cost-effective and accessible for a broader range of industries. This includes reducing energy consumption during the production of carbon fibers, which could lead to more sustainable manufacturing practices.

Another area of innovation is in the development of hybrid composites that combine carbon fibers with other materials to enhance their properties. These hybrid composites could offer even greater strength, durability, and flexibility than current carbon fiber materials, opening the door to new carbon fiber applications in fields like medical devices, renewable energy, and construction.

Additionally, recycling carbon fiber is becoming an increasingly important focus. Traditionally, carbon fiber composites have been difficult to recycle, but advancements in this area could lead to more sustainable usage of this powerful material. Recycled carbon fiber could be used in lower-stress applications, reducing waste and contributing to a more circular economy.

Conclusion

The rise of carbon fiber reinforcement is shaping the future of lightweight manufacturing across various industries. From aerospace composites that enable more efficient air travel to carbon fiber in automotive applications driving the future of electric and hybrid vehicles, carbon fiber is a key material for innovation. As the world continues to push for more sustainable, efficient, and high-performance solutions, the role of carbon fiber reinforcement will only become more prominent.

To learn more about carbon fiber reinforcement and its applications in advanced composites, visit NitPro Composites. Here, you can explore cutting-edge innovations and the latest developments in lightweight materials and composites technology.