Carbon Fiber Vs. Fiber Glass: What's the Difference

👁 Reads: 2635

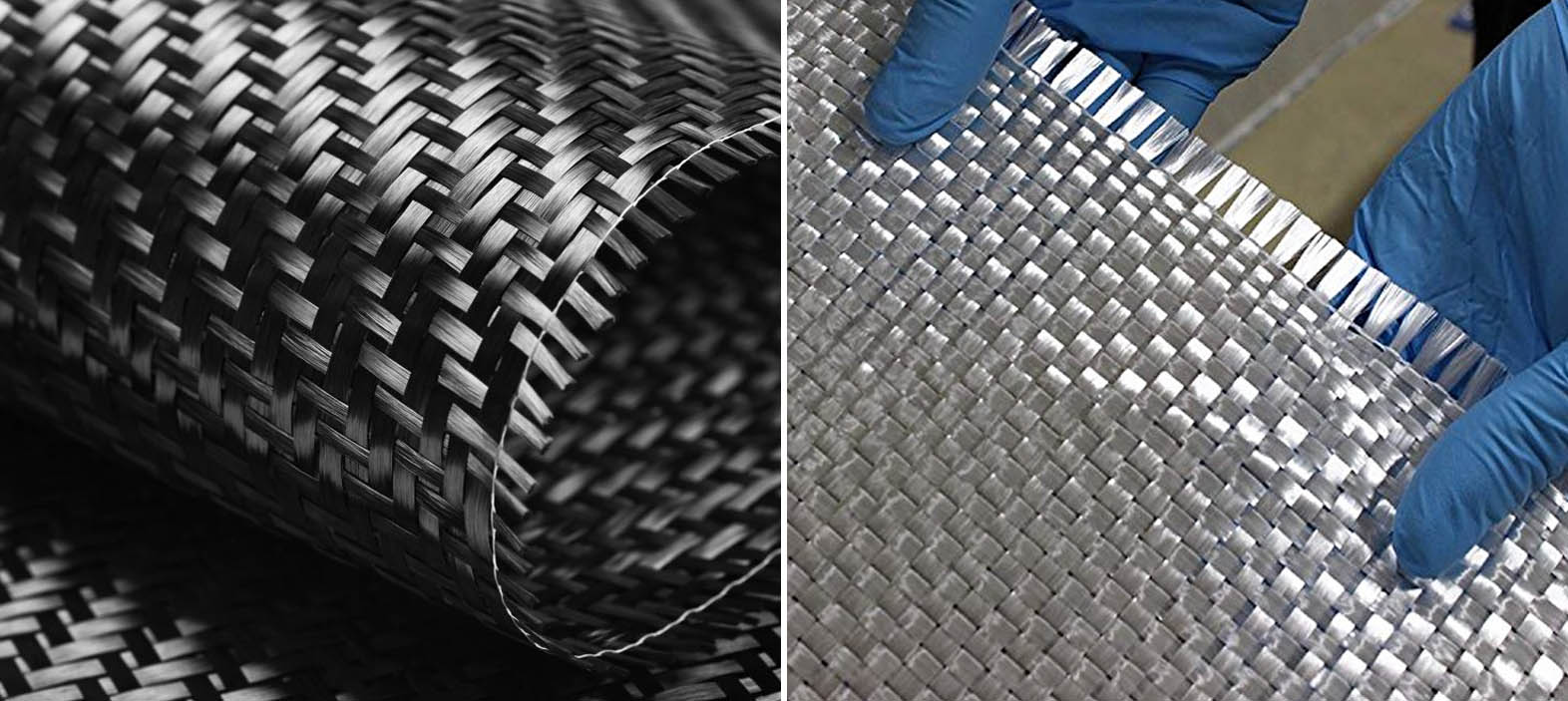

Carbon fiber and fiberglass are two popular composite products that have been used in various industries, such as aerospace, automotive, and marine. While both materials have similar properties, they differ in several aspects. In this article, we will discuss the differences between carbon fiber and fiberglass, and their respective strengths and weaknesses.

Carbon Fiber

It is a composite material made of carbon fibers and a resin matrix. These are thin, long strands of carbon atoms that are tightly woven together to create a strong and lightweight material. The carbon fibers are typically mixed with a resin matrix, such as epoxy, to create a composite material that is both strong and flexible.

One of the primary advantages of carbon fiber is the strength-to-weight ratio. Incredibly strong and light in weight makes it an ideal material for applications that require both strength and flexibility. Also resistant to corrosion and can withstand high temperatures, ensuring a suitable material for applications in harsh environments.

However, carbon fiber products are more expensive than fiberglass, which makes them less accessible for some applications. Additionally, Carbon Fiber Tube is not as impact-resistant as fiberglass, which makes the material less suitable for applications that require impact resistance.

Fiberglass

Fiberglass is a composite material made of glass fibers and a resin matrix. Glass fibers are made of thin strands of glass that are tightly woven together to create a strong and flexible material. The glass fibers are typically mixed with a resin matrix, such as polyester or epoxy, to create a composite material that is both strong and flexible.

One of the primary advantages is its affordability. Much cheaper than carbon fiber, making it a more accessible material for many applications. Additionally, fiberglass is more impact-resistant, which makes it a suitable material for applications that require impact resistance.

However, this composite material is not as strong or lightweight, therefore less suitable for applications that require both strength and flexibility. Additionally, it is not as resistant to high temperatures, which makes it less suitable for applications in harsh environments.

Applications of Carbon Fiber and Fiberglass

Carbon fiber and fiberglass are both used in various applications across several industries. Here are some examples of where each material is commonly used:

Carbon Fiber Applications:

- Aerospace: Used in the design of aircraft and spacecraft components, such as wings and fuselages, to reduce weight and increase strength.

- Automotive: Effective in the design of high-performance vehicles to reduce weight and improve fuel efficiency.

- Sporting Goods: Roll Wrapped Carbon Fiber Tube is used in sporting goods, such as bicycles and golf clubs, to improve performance and reduce weight.

- Marine: Effective for the design of boats and watercraft to reduce weight and increase strength.

Fiberglass Applications:

- Construction: Used in construction materials, such as insulation and roofing, due to its durability and affordability.

- Automotive: Effecautomotive body panels due to its impact resistance.

- Marine: The key points of affordability and impact resistance is the reason that is suitable for the design of boats and watercrafts.

- Consumer Goods: Even for consumer goods, such as furniture and appliances, the composite material scores extra points due to affordability and durability.

Properties of Carbon Fiber and Fiberglass

Carbon fiber and fiberglass have different properties that make them suitable for different applications. Here are some of the key properties of both materials:

- Strength: A high strength-to-weight ratio, meaning it is incredibly strong but also lightweight. Fiberglass is also strong, but not as strong as carbon fiber.

- Flexibility: Carbon fiber sheet is flexible and can be molded into different shapes, making it ideal for applications that require flexibility. Fiberglass is also flexible, but not as flexible as carbon fiber.

- Corrosion Resistance: Both materials are resistant to corrosion, making them suitable for use in harsh environments.

- Thermal Resistance: Carbon fiber is resistant to high temperatures and can withstand extreme heat. Fiberglass is also heat-resistant, but not as resistant.

- Impact Resistance: Fiberglass is more impact-resistant than CNC Carbon Fiber Parts, therefore suitable for applications that require impact resistance.

- Cost: Fiberglass is more affordable, making it a more accessible material for many applications.

Manufacturing Processes

The manufacturing processes for carbon fiber and fiberglass differ. Carbon fiber is typically produced by heating and then combining them with a resin matrix, which is then cured to create a strong and flexible composite material. Fiberglass is made by weaving glass fibers together and then combining them with a resin matrix, which is then cured to create a composite material.

The manufacturing process for carbon fiber is more complex and expensive than the process for fiberglass. It requires high temperatures and specialized equipment to produce, whereas fiberglass can be produced with less specialized equipment and at lower temperatures. This is one reason why carbon fiber is more expensive than fiberglass.

Conclusion

In summary, both are two composite materials that differ in several aspects. Carbon fiber is incredibly strong and lightweight, making it suitable for applications that require both strength and flexibility. However, It is more expensive than fiberglass and is not as impact-resistant.

Fiberglass is more affordable and impact-resistant, making it suitable for applications that require impact resistance. However, it is not as strong or lightweight and is not as suitable for applications that require both strength and flexibility.

Ultimately, the choice between carbon fiber and fiberglass depends on the specific application and the desired properties of the material. Both materials have their respective strengths and weaknesses, and the decision to use one over the other should be based on the specific needs of the project. For example, if weight reduction and high strength are the primary concerns, It would be the better choice. On the other hand, if impact resistance and affordability are the primary concerns, fiberglass would be the better choice.