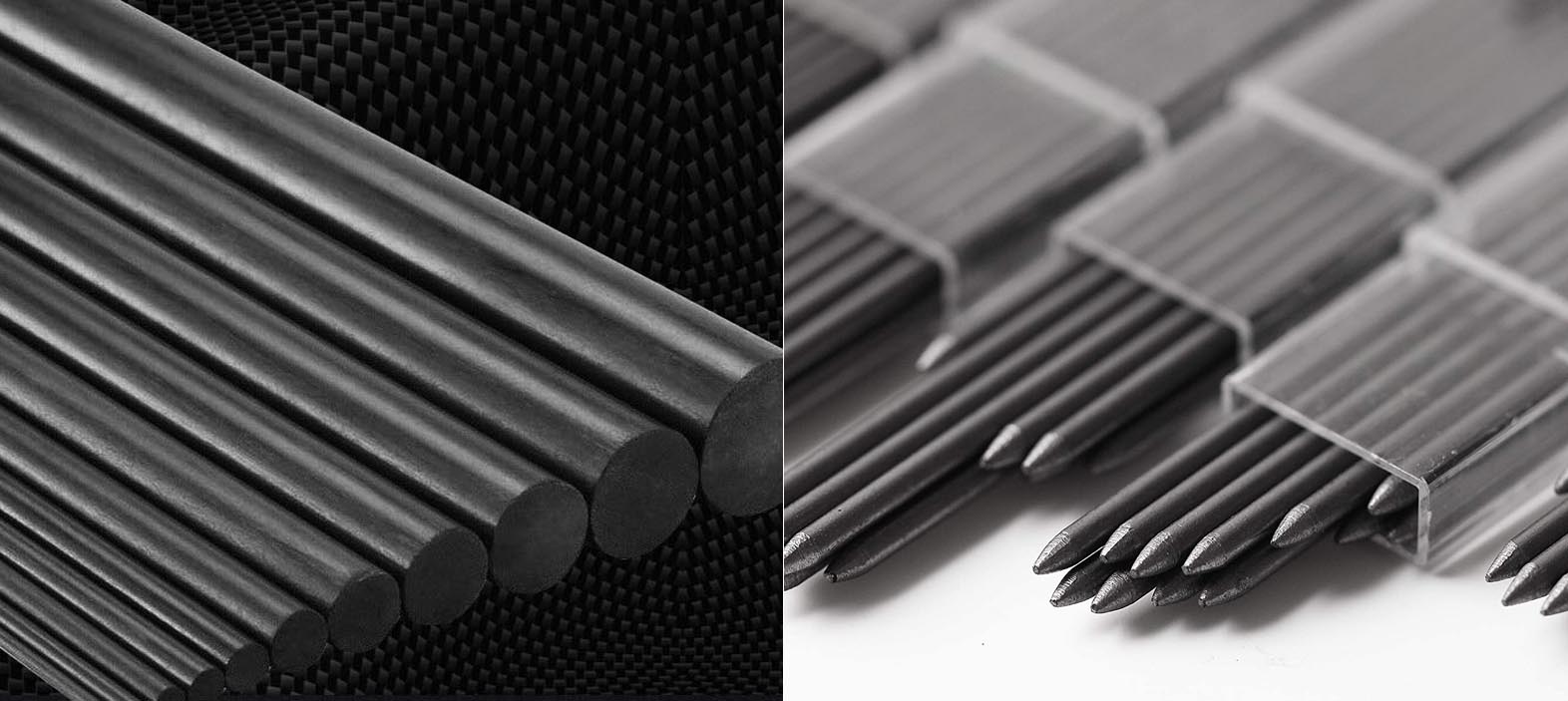

Carbon Fiber versus Graphite: Everything you need to Know

👁 Reads: 236

Carbon fiber and graphite are two materials that are often used in various industries due to their unique properties. While they share some similarities, they also have distinct differences. Carbon fiber is used in industries where their exceptional mechanical properties of high strength to low weight ratio is well used. The composite materials differ in their manufacturing processes and technologies. Carbon fiber products are manufacture.

Let's explore each material and highlight their characteristics, applications, and differences.

1. Carbon Fiber

Carbon fiber is a composite material composed of thin strands of carbon atoms, which are extremely strong and lightweight. The carbon fibers are typically combined with a polymer matrix, such as epoxy resin, to create a strong and durable material. Here are some key points about carbon fiber:

Properties:

Strength: Carbon fiber has an exceptional strength-to-weight ratio, making it stronger than many metals while remaining much lighter.

Stiffness: It is known for its high stiffness, providing excellent rigidity and stability to structures.

Lightweight: As mentioned earlier, carbon fiber is very light, making it ideal for applications where weight reduction is crucial.

Corrosion-resistant: Carbon fiber is highly resistant to corrosion, making it suitable for use in harsh environments.

Applications of Carbon Fiber :

Aerospace: Carbon fiber is extensively used in the aerospace industry for aircraft components, such as wings, fuselage parts, and structural reinforcements.

Automotive: It is employed in high-performance vehicles to reduce weight and improve fuel efficiency and overall performance.

Sports equipment: Carbon fiber is used in sports equipment like bicycles, tennis rackets, golf clubs, and even helmets, providing strength and lightness.

Wind energy: Carbon fiber is used in wind turbine blades due to its strength and resistance to fatigue.

Marine: Carbon fiber finds applications in marine vessels, boat hulls, and components where weight reduction is beneficial.

2. Graphite

Graphite is a form of carbon, but unlike carbon fiber, it is a crystalline material. It consists of layers of carbon atoms arranged in a hexagonal lattice structure. Graphite has unique properties that make it suitable for various applications:

Properties:

Lubrication: Graphite has excellent lubrication properties due to its layered structure, where the layers slide over each other easily.

Thermal conductivity: It is a good conductor of heat, allowing it to be used in heat sinks and other thermal management applications.

Electrical conductivity: Graphite is also an excellent conductor of electricity, making it useful in electrical components and batteries.

High-temperature resistance: Graphite can withstand high temperatures without significant degradation, making it suitable for high-temperature applications.

Applications of Graphite:

Electronics: Graphite is used in electrical components like electrodes, brushes, and contacts due to its electrical conductivity.

Refractories: It is used in the production of refractory materials, which are resistant to high temperatures and used in industrial furnaces and kilns.

Batteries: Graphite is commonly used as an anode material in lithium-ion batteries.

Foundry: Graphite molds are used in metal casting processes due to their high-temperature resistance and lubrication properties.

Differences

Structure: Carbon fiber is a composite material made of thin carbon fibers embedded in a polymer matrix, while graphite is a crystalline form of carbon with a layered atomic structure.

Strength and Stiffness: Carbon fiber has exceptional strength and stiffness, making it suitable for structural applications, while graphite's properties focus more on electrical and thermal conductivity.

Applications: Carbon fiber is primarily used in industries where lightweight, high strength, and rigidity are essential, such as aerospace, automotive, and sports equipment. Graphite, on the other hand, finds its main applications in electrical components, heat management, and refractories.

In summary, carbon fiber and graphite are both forms of carbon with distinct properties that make them valuable for various applications. Carbon fiber's strength, lightweight nature, and durability suit it well for industries seeking high-performance materials, whereas graphite's conductivity and heat resistance make it a preferred choice for electrical and thermal applications.

Carbon Fiber Products and its uses

Carbon fiber products have gained popularity due to their excellent strength-to-weight ratio, durability, and aesthetic appeal. Here are some popular carbon fiber products that you can commonly find in various industries:

Rods, Tubes, Sheets, CNC Parts

- Aerospace Components including wings, fuselage parts, tail sections, and interior panels. Its lightweight nature helps reduce fuel consumption and enhance aircraft performance.

- Automotive Parts of high-performance and luxury cars include hoods, fenders, spoilers, mirror covers, interior trim pieces, and even entire chassis structures.

- Sports Equipment such as bicycle frames, handlebars, and wheels; tennis rackets; golf club shafts; hockey sticks; and ski and snowboard components.

- Marine vessels and boat components to reduce weight and improve performance. This includes sailboat masts, hulls, deck panels, and various structural elements.

- Wind Turbine Blades to harness wind energy efficiently and have a longer service life.

- Consumer Electronics such as smartphones, tablets, laptops, and other electronic devices. It adds a premium look and feel to these products.

- Medical Devices like wheelchairs, prosthetics, braces, and medical imaging equipment.

- Luxury Goods like watches, wallets, pens, and fashion accessories.

- Industrial Equipment including robotic arms, lifting equipment, and parts in machinery where weight reduction and strength are crucial.

- Aircraft Interiors such as seat frames, cabin panels, and overhead bins, to make aircraft cabins lighter and more stylish.

- Musical Instruments like guitars and violin bows.

These are just a few examples of popular carbon fiber products. As technology and manufacturing techniques advance, carbon fiber is likely to find even more applications in different industries, offering enhanced performance and design possibilities.

For all your composite needs, experience the strength and beauty of NitPro Composites carbon fiber sheets, rods, tubes, CNC parts and more. Our high-quality carbon fiber composites are created through advanced molding and infusion techniques, ensuring durability and consistency. With a glossy surface finish and varying thickness options, our carbon fiber sheets can be customized to meet your specific needs. Trust in our uncompromising quality and craftsmanship to enhance your projects.