Carbon Fiber vs. Graphite Rod: Which is Better for Your Needs?

👁 Reads: 3875

When it comes to high-strength, lightweight materials, carbon fiber and graphite rods are two of the most popular choices in industries like aerospace, orthopedics, sports equipment, and even hobby crafting. Each material brings unique properties that cater to specific applications, making the decision between carbon fiber and graphite a matter of understanding their differences and capabilities. This blog explores these materials in depth, focusing on carbon fiber rods and the various benefits of carbon fiber products, including carbon fiber pultruded rods.

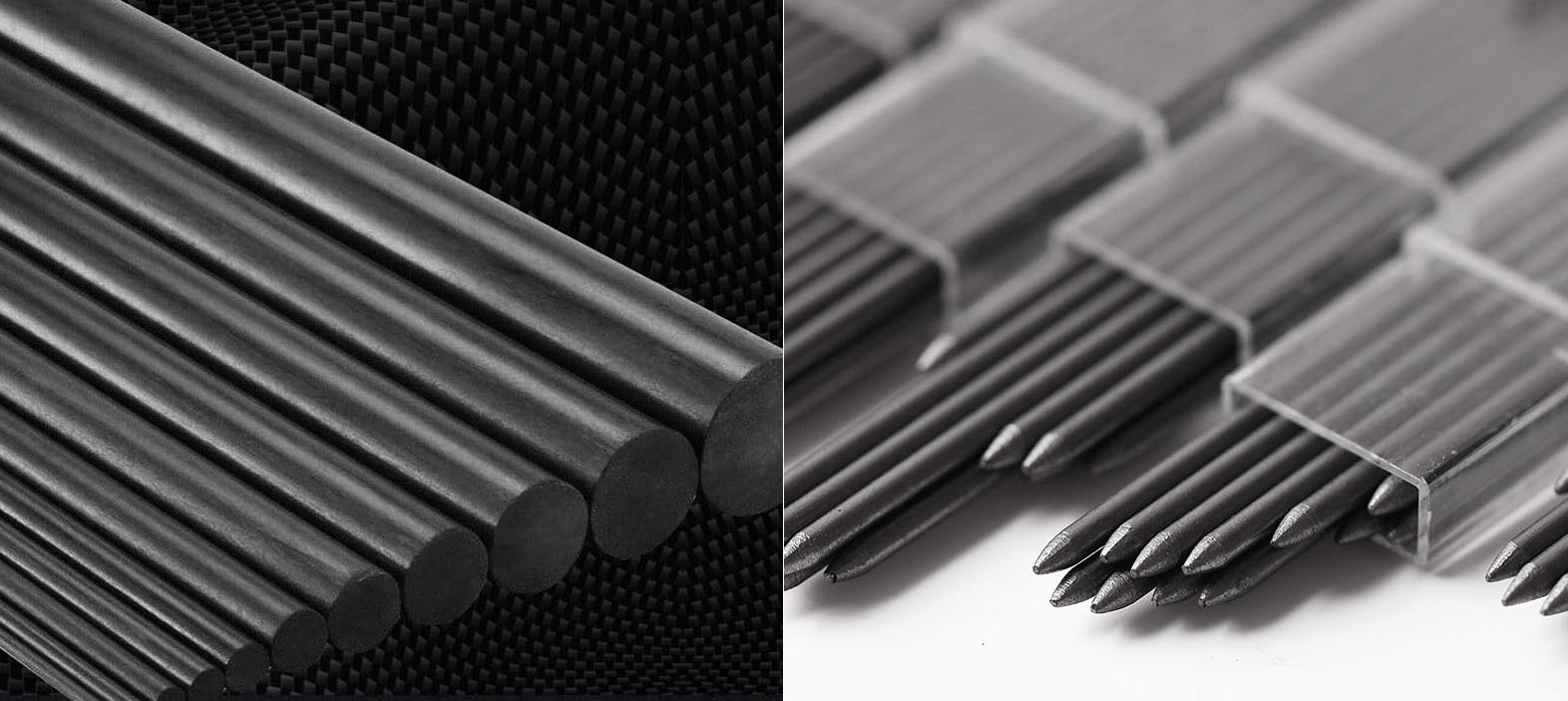

What Are Carbon Fiber Rods?

Carbon fiber rods are thin, lightweight structural elements made from layers of carbon fiber-reinforced polymers. Carbon fibers themselves are extremely strong and stiff, derived from materials like polyacrylonitrile (PAN) or pitch. During the manufacturing process, carbon atoms bond tightly in long chains, giving the material its renowned strength-to-weight ratio.

One of the primary processes used to make carbon fiber rods is pultrusion. In this method, continuous strands of carbon fiber are pulled through a resin bath and then into a heated die, which shapes them into solid, consistent rods. The result is a carbon fiber pultruded rod that’s ideal for high-performance applications requiring both strength and stiffness.

What Are Graphite Rods?

Graphite rods, on the other hand, are made from pure graphite or carbon, sometimes enhanced with various polymers to achieve specific properties. Unlike carbon fiber, which is highly engineered and layered for strength, graphite is formed through pyrolytic deposition or graphitization. This process aligns carbon atoms in a lattice structure, resulting in a stable yet brittle rod that can withstand high temperatures but is generally less flexible than carbon fiber.

Key Differences Between Carbon Fiber and Graphite Rods

Strength and Durability

When comparing carbon fiber rods and graphite rods, one of the main factors is strength. Carbon fiber is renowned for its high tensile strength and rigidity, capable of withstanding immense forces without breaking or deforming. This makes it a preferred choice for industries that require reliable, high-strength materials, such as aerospace and automotive manufacturing.

Graphite, while strong, is more brittle than carbon fiber. It can withstand heat and pressure up to a certain point but is prone to fracture under high-stress conditions. This makes graphite rods less durable in high-impact applications but still useful for scenarios where heat resistance is critical.

Weight and Flexibility

Carbon fiber products are known for their excellent strength-to-weight ratio. Carbon fiber is lightweight but incredibly stiff, making it ideal for applications where reducing weight without sacrificing strength is essential. The pultruded manufacturing process enhances this property, producing carbon fiber pultruded rods with uniform strength and flexibility.

Graphite rods, however, are typically denser and heavier than carbon fiber. They are less flexible and may crack under sudden stress or impact. For applications where lightness and flexibility are prioritized, carbon fiber is generally the better choice.

Resistance to Environmental Factors

Carbon fiber rods have a high resistance to environmental factors such as UV radiation, moisture, and corrosion. This makes them suitable for outdoor applications, where exposure to the elements can degrade other materials. Carbon fiber products maintain their structural integrity over time, making them a reliable option for various challenging environments.

Graphite rods, although resistant to high temperatures, can be susceptible to corrosion and weathering, especially in humid or chemically reactive environments. This makes them less ideal for long-term outdoor applications where exposure to environmental elements could compromise their structure.

Applications of Carbon Fiber and Graphite Rods

Both carbon fiber and graphite rods have unique applications:

- Carbon Fiber Rods: Widely used in aerospace, robotics, automotive, and sporting goods due to their lightweight and high-strength properties. Carbon fiber pultruded rods are often utilized in load-bearing structures and mechanical arms where consistent strength and low weight are essential.

- Graphite Rods: Primarily used in high-temperature environments, such as foundries, and in applications like welding and crucibles. They are also valuable in chemical applications where heat resistance is more important than tensile strength.

Why Choose Carbon Fiber Rods?

Carbon fiber rods offer an unparalleled combination of lightness, strength, and durability. When choosing between carbon fiber and graphite, consider the demands of your specific application. For load-bearing or high-stress applications, carbon fiber rods, especially those created through the pultruded process, offer reliability, strength, and longevity that graphite rods may not provide.

In conclusion, while both carbon fiber products and graphite rods have their merits, carbon fiber rods offer more advantages for various demanding applications. With higher strength-to-weight ratios, superior flexibility, and durability in adverse conditions, carbon fiber pultruded rods are a standout choice. Whether for aerospace engineering, automotive design, or sports equipment, carbon fiber products meet the needs of modern industries seeking advanced, resilient materials.

Choosing the right material involves understanding these unique properties and selecting the one that best fits the requirements of your project. For those in need of durable, lightweight solutions, carbon fiber rods are a top choice.