How Carbon Fiber Rods Are Made?

👁 Reads: 497

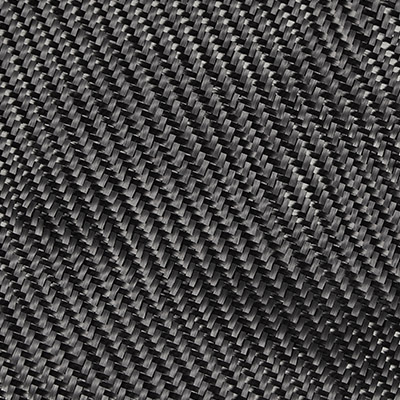

Carbon fiber rods are made of carbon fiber, which is a strong, lightweight material. Carbon fiber is made from thin, strong fibers of carbon. The fibers are woven together to form a rod. The rods are then heated to high temperatures, which makes them hard and strong. Carbon fiber rods are used in a variety of applications, including aircraft and spacecraft.

Manufacturing Carbon Fiber rods

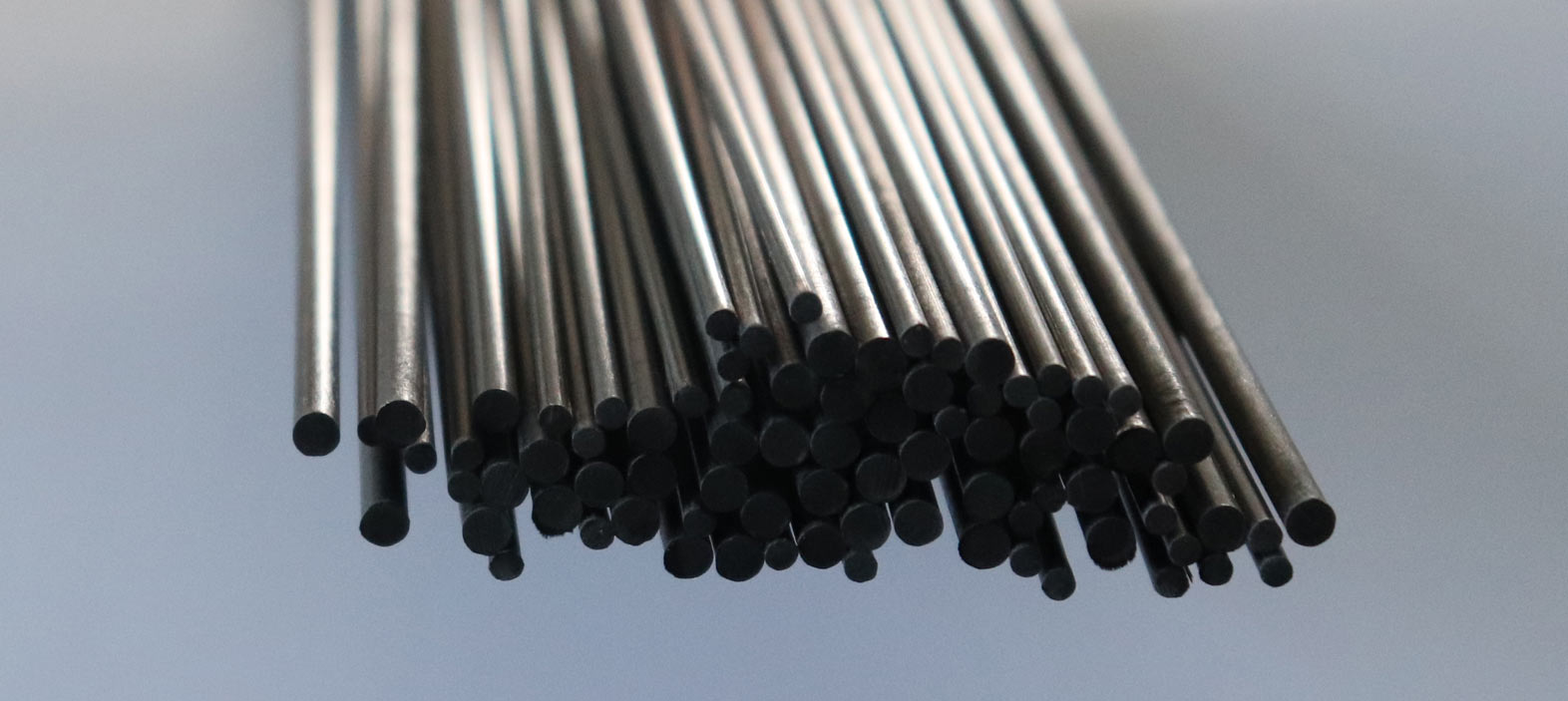

Carbon fiber rods are used in a variety of industries, from aerospace to automotive. They are made from a variety of materials, including carbon fiber, Kevlar, and fiberglass. Carbon fiber rods are made by layering sheets of carbon fiber and epoxy resin and curing them under heat and pressure. The resulting rods are strong and lightweight, with a high resistance to wear and tear. Carbon fiber rods can be used in a variety of applications, including structural support, reinforcement, and weight reduction. Carbon fiber rods are used in a variety of industries, from aerospace to automotive. Pultruded carbon fiber rods are extremely strong and lightweight, making them ideal for a variety of applications.

- The manufacturing process of carbon fiber rods begins with the spinning of a raw material, usually polyacrylonitrile (PAN), into a thread. The thread is then heated to high temperatures, which causes it to change shape and become stronger.

- Once the thread has cooled, it is ready to be used in the manufacturing process. Carbon fiber rods are typically made by layering the thread onto a mandrel, or rod-shaped mold. The mandrel is then placed into a furnace and heated to high temperatures.

- As the mandrel is heated, the thread begins to melt and form around the mandrel. Once the desired shape has been achieved, the mandrel is cooled and the carbon fiber rod is removed.

- The manufacturing process of carbon fiber rods is very similar to that of carbon fiber tubes. The main difference is the size of the mandrel used. Carbon fiber rods typically have a diameter of less than 1 inch (2.54 cm), while carbon fiber tubes have a diameter of more than 1 inch (2.54 cm).

Carbon fiber rods are used in a variety of industries because of their unique properties. They are extremely strong and lightweight, making them ideal for use in aerospace and automotive applications.

Applications of carbon fiber rods

Carbon fiber rods are one of the most versatile and widely used composite materials available today. They have a wide range of applications in a variety of industries, including aerospace, automotive, marine, and sporting goods.

Aerospace

Carbon fiber rods are often used in the aerospace industry for their high strength-to-weight ratio and resistance to fatigue and impact damage. They are commonly used in the construction of aircraft and spacecraft components, including fuselage frames, bulkheads, and landing gear.

Automotive

Carbon fiber rods are also used extensively in the automotive industry, where they are often used in the construction of racing cars and high-performance vehicles. They are also used in the construction of some consumer vehicles, such as the BMW i3 and i8.

Marine

Carbon fiber rods are also used in the marine industry, where they are often used in the construction of boat hulls and other marine structures. These customized carbon fiber rods are also used in the construction of some marine propulsion systems.

Sporting Goods

CF rods are also used in the construction of some sporting goods, such as tennis racket frames, golf club shafts, and fishing rod blanks.

Summing up

Carbon fiber rods are made from carbon fiber that is heated and then extruded into the desired shape. The rods are then cooled and cut to the desired length. The use of carbon fiber rods has a number of advantages over traditional materials. They are lighter and stronger, making them ideal for use in a variety of applications. In addition, carbon fiber rods are resistant to corrosion and have a high resistance to thermal and electrical conductivity.