How Carbon Fiber Sheets Are Made?

👁 Reads: 3485

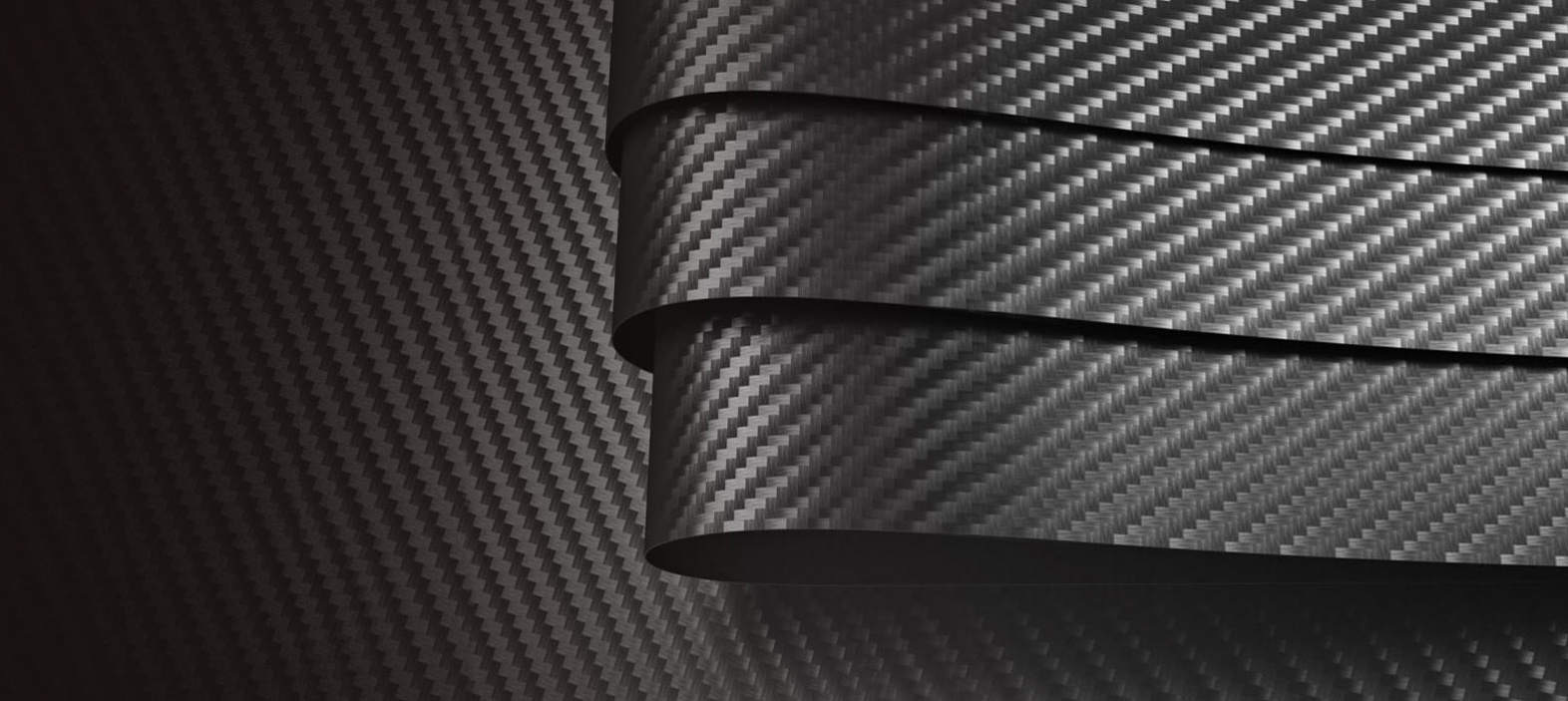

Carbon fiber sheets are lightweight yet strong, making them a popular choice in a variety of industries. But how are they made? In this article, we’ll explain the process of manufacturing these sheets.

METHOD 1

Carbon fiber sheets are a popular material choice for a wide range of applications due to their light weight, strength, and stiffness. They are used in everything from aerospace components to sporting goods and even luxury items like high-end watches. But how exactly are carbon fiber sheets produced?

Precursor

The process of making carbon fiber sheets starts with a raw material called a precursor. These are usually organic or inorganic materials that are heated and pressurized in order to break down the molecular structure. This causes the fibers to be formed from the long molecular chains.

Align the Fibers in a Specific Direction

The next step is to align the fibers in a specific direction in order to create a unidirectional material. This is done by using a process called pultrusion. This involves pulling the precursors through a heated die, where the fibers are heated and aligned in the desired direction.

Woven Into a Cloth or Other Fabric

Once the fibers are aligned, they are woven into a cloth or other fabric and then heat-set in an oven. The heat helps to fuse the fibers together and make them more durable. This also helps to create a flat and uniform surface.

Impregnate the Fabric with Resin

The next step is to impregnate the fabric with resin. This is done by either soaking the fabric in the resin or injecting it directly into the fabric. This gives the Carbon fiber composite sheet fabric strength and stiffness.

Carbon Fiber Sheets Are Cured With Heat and Pressure

Finally, the carbon fiber sheets are cured with heat and pressure in order to harden the resin and create the desired shape and thickness. The sheets can then be cut and shaped into the desired product.

METHOD 2

Carbon fiber sheets are used in a variety of applications due to their unique properties and light weight. They provide strength and stiffness, while also being lightweight and durable. By understanding the process of how they are made, it's easy to see why they are such a popular material choice.

Production of Carbon Fibers

The production of carbon fiber sheets begins with the production of carbon fibers. The fibers are made from a combination of polyacrylonitrile (PAN) and other organic materials. To make the fibers, the PAN is heated and stretched to form long strands. These strands are then heated and stretched again, before being wound onto spools.

Resin Mixing and Sheet Cutting

Next, the carbon fibers are collected and mixed with a resin. This resin helps to bind the fibers together and give the sheet its strength. The mixture is then placed into a mold, which is heated and pressurized to form the desired shape. The sheet is then cut to the desired size and shape.

Sheet Coating and Treatment

Once the sheet is cut, it is ready for treatment. Depending on the desired end-product, the sheet may be coated with a protective layer or treated with a chemical solution. For example, the sheet may be coated with a wax or resin to make it waterproof, or it may be treated with an epoxy resin to add strength and stiffness.

Sheet Cutting

The final step is to cure the sheet. The curing process involves heating the sheet to a high temperature, usually between 300 and 400 degrees Celsius. This hardens the resin and binds the fibers together. The result is a strong and lightweight carbon fiber sheet.

Carbon fiber sheets have a number of applications, from aerospace to automotive. They are lightweight, yet strong, and can be used in a variety of industries that is why industrial people prefer to buy carbon fiber sheets. They are also relatively inexpensive and easy to manufacture. With the right tools and knowledge, anyone can make a carbon fiber sheet.