How to cut Carbon fiber?

👁 Reads: 351

Owing to their exceptional physical properties, carbon fibers are nowadays an important raw material used in the composite, and carbon fiber products industry and find wide application in the aerospace, automotive, wind energy, body protection industry, as well as in other emerging fields. Carbon fibers are often molded using specific resins to make useful components.

In order to give shape to composite materials, they need to be often cut in complicated profiles. The materials to be cut may be in the form of RAW fabrics or pultruded carbon fiber tubes, as prepreg tubes, sheets or plates.

The implications of cutting will relate with the type of, or condition of the material being cut and various are the factors which we shall cover in this blog

Issues with Cutting Carbon Fiber:

Before we move on to the cutting devices let us look at the issues particularly related to the behavior of carbon fibers:

- Fiber flatness: The fiber tends to be wavy at times and this may affect accuracy of cutting shapes

- Dust: when cutting the fiber, dust will fly which may fall on the cutting surfaces and pollute the environment besides posing danger to the operator

- Marking: because of the dark color, (generally black) of carbon fibers, marking of particular shape to be cut can be challenging. Pencils may not work for proper marking and one needs to use specific tools

- Resin: the resin embedded in the composite may evaporate into toxic fumes which could pose danger to the operator

Cutting devices

The available cutting devices can be classified into the following main types: Manual or Automatic devices.

Whereas the manual devices can be used to cut most forms of materials to be cut, including pultruded pipes or structural members, the automatic machines are generally used for cutting flat fibers or fabrics or sheets.

When using manual devices, it is advisable to use a table with an inbuilt down-draft vacuum system, and/or with dedicated fume extractors.

Manual Devices:

- Rotary manual cutters: Hand tools could be a simple as angle grinders using tungsten carbide disc or a serrated, sawed disk. They may come with a fixed speed, or variable. These devices are generally used for fast cutting of straight lines as it may be difficult to maneuver them around curved profiles. The serrated or saw type disc may pose some challenge with resins if embedded in the material being cut as the resin material make clog the spaces between teeth.

- Jigsaws: Jigsaws are handy tools that use relatively thin blades and are easier to maneuvers over covered profiles

- Flexible trammels: Flexible trimmers are another type of useful handy tools that are slim and come with flexible shaft powered from a remote motor. They are relatively easier to move around curved profiles. Trammels can come with tungsten carbide discs or ceramic discs depending on applications

- Hacksaws: hacksaws are the simplest manual cutting tools that can only be used on an over hanging portion of a molded carbon fiber material as they have limited possibility to penetrate a flat surface on a table and their blade can wear out very fast needing frequent changes.

Automatic Devices:

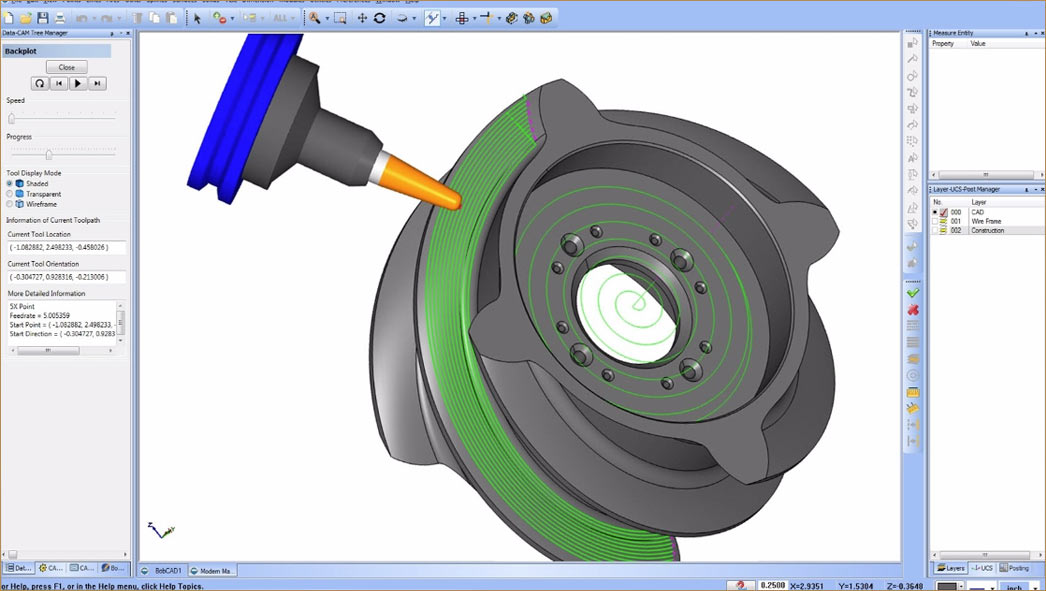

- CNC Router: A CNC router is a universal tool used for many applications of material removal. It is a flat bed, computer controlled machine wherein, a thin sharp edged tool (blade) is made to move on a predefined path according to the profiles to be cut. A router generally is used to cut fabrics in single ply. It will have a soft top surface to allow penetration of the free end of the blade

- CNC Knife Cutting Machines: CNC cutting machines use reciprocating knife technology and are similar to the router but are generally better known as CAD CAM systems. These machines come with a flat bed which may be either fixed or conveyorized.

A choice of knives/blades maybe available to cut different kind of materials. Like the router, these machines are operated form an inbuilt personal computer wherein, files can be accessed of profiles to be cut. CNC cutting machines can be used for cutting carbon fabrics in multiply as they are provided with bristle blocks which allow the penetration of the free end of the knife below the material to be cut, thus offering good quality cut in the most intricate of shapes.

When you want to cut several pieces of material from the given fabric or molded material, a CNC cutting machine has the possibility of achieving the highest optimization of usage of raw material, thus minimizing wastage as the profiles of individual pieces can be suitably laid on a predefined marker across the width of the fabric to be cut. Such an activity actually provides more advanced information about the total amount of raw material required to cut the lot.

Conclusion:

An experienced operator will choose the most suitable of the cutting tools or devices based on various factors which can be summarized as follows:

- Nature of shapes to be cut

- Nature of material to be cut

- Cost of materials, and the need to economize

- Available type and size of raw material to be cut

- Speed of cutting

- Accuracy Levels