Introduction to Continuous Carbon Fiber

👁 Reads: 293

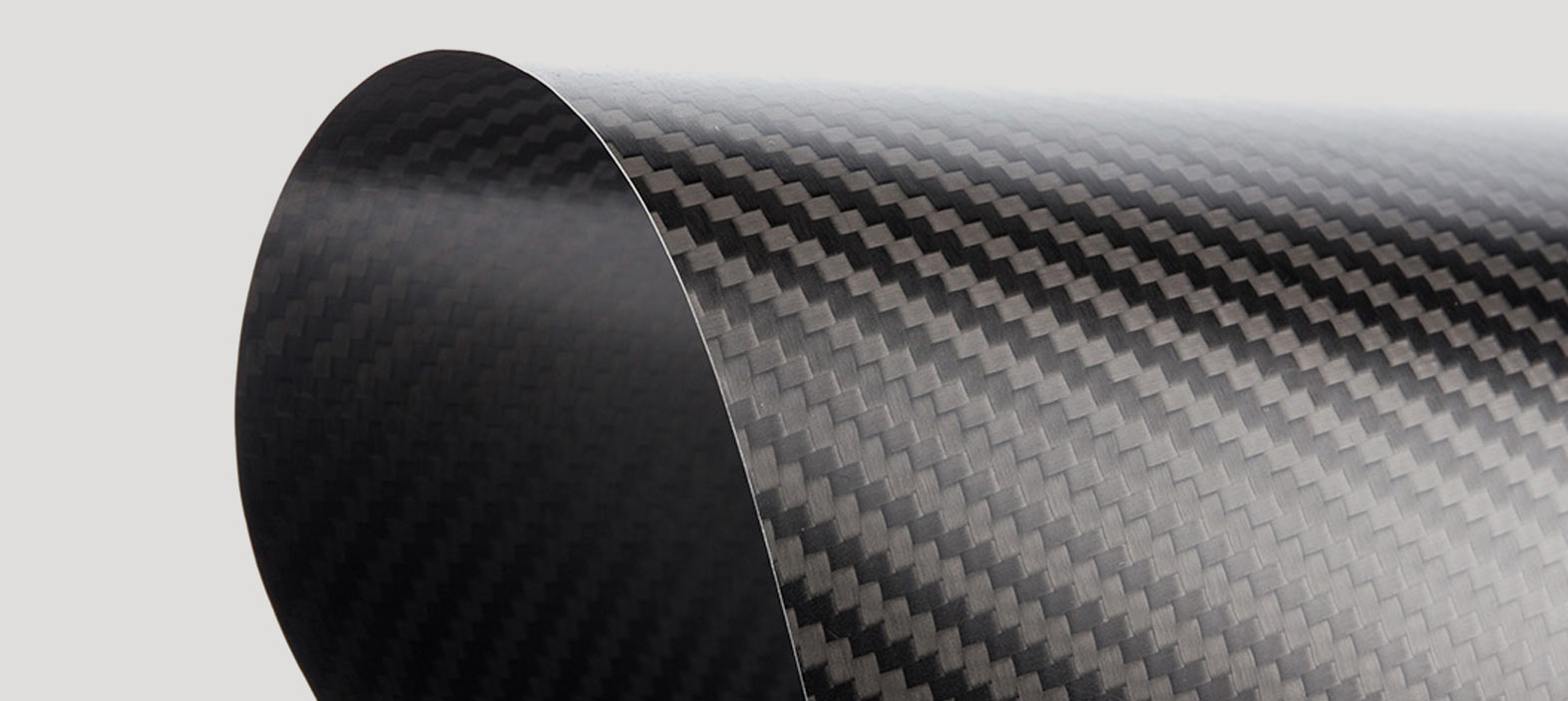

When it comes to cutting-edge materials, carbon fiber is unique as a ground-breaking innovation that is revolutionizing many different industries. Continuous carbon fiber, one of the many varieties of carbon fiber, has special advantages that make it essential for high-performance applications. Reinforcement materials such as continuous carbon fiber are used to increase the stiffness and strength of structures or parts. The concept of using continuous carbon fiber for reinforcement is based on its special qualities. Even when compared to metals, its tensile strength is extremely strong, enabling the creation of parts with anisotropy and manipulation of it in the necessary directions inside the structure of a printed part. Keep reading as we explore the basics of continuous carbon fiber, its properties, and its diverse applications, focusing on carbon fiber products; carbon fiber fabric and carbon fiber sheets.

What is Continuous Carbon Fiber?

Continuous carbon fiber is composed of long, continuous strands of carbon atoms bonded together in a crystal alignment. This alignment provides the fibers with exceptional strength and stiffness. Continuous carbon fiber is made by drawing long, thin strands of carbon fibers into a continuous yarn and then woven into carbon fiber fabric, which can be used directly or processed into various carbon fiber products. Continuous carbon fiber differs from chopped or short fibers in that it offers superior mechanical properties due to the uninterrupted nature of the fibers. This material offers a high strength-to-weight ratio, making it stronger and lighter than steel or aluminium. Continuous carbon fiber is ideal for applications where strength and weight are critical like in aerospace, automotive, and sporting goods.

Properties of Continuous Carbon Fiber

Continuous carbon fiber is a highly sought-after material in many industries due to its many important features. Continuous carbon fiber is primarily appealing due to its exceptional strength-to-weight ratio. It has equivalent, if not greater, strength to metals like steel and aluminium yet is much lighter. This feature is especially helpful in sectors like aircraft, automobile, and sports equipment manufacturing where reducing weight is essential. Because continuous carbon fiber has a high fatigue resistance and can bear repeated stresses without breaking, it is a good material for structural components that are subjected to cyclic loadings. Furthermore, carbon fiber has a high level of corrosion resistance, which makes it perfect for abrasive situations. Under temperature variations, its low thermal expansion coefficient guarantees dimensional stability. Usually, continuous carbon fiber is utilized to create composite materials, where the fibers are immersed in a matrix of binding agents or resin. This results in a material that is resilient to impact, flexible, robust and stiff.

Applications of Continuous Carbon Fiber

Continuous carbon fiber has a wide range of applications across various industries due to its exceptional properties. Some of the key applications of continuous carbon fiber include:

Automotive Industry: In the automotive industry, continuous carbon fiber products, including carbon fiber sheets, are used to create lightweight yet durable auto parts. From body panels, drivetrain components, and suspension parts to interior components, the use of continuous carbon fiber products helps to reduce vehicle weight and improve performance.

Aerospace Industry: Continuous carbon fiber is extensively used in the aerospace sector for manufacturing aircraft components such as wing spars, fuselage panels, and bulkheads. The reduced weight of continuous carbon fiber fabric translates to improved fuel efficiency and higher payload capacities.

Sports Equipment: Continuous carbon fiber can be used to make composite materials for use in sporting equipment. Continuous carbon fiber fabric allows manufacturers to create products that enhance athletic performance. High-performance sports equipment, such as racing bicycles, tennis rackets, skis, fishing rods and golf clubs, benefit from the strength and lightness of continuous carbon fiber.

Construction and Civil Engineering: Continuous carbon fiber can be used to make composite materials for use in construction, including bridge decks, beams, and columns. Also, continuous Carbon fiber sheets are increasingly used in construction for reinforcing concrete structures. The strength and durability of continuous carbon fiber products help in extending the lifespan of buildings, bridges and other civil engineering structures.

Other Applications: Continuous carbon fiber also finds applications in various fields, it is used to manufacture composite wind turbine blades, which are typically longer and more flexible than traditional blades, improving efficiency and performance. In the marine industry, continuous carbon fiber is used to produce composite materials for boat hulls and other applications requiring strength and corrosion resistance. Also, they are used in medical devices such as implantable devices and prosthetics, providing strength and biocompatibility. Additionally, continuous carbon fiber is used in various consumer products like electronics and appliances, where its strength and lightweight properties are beneficial.

Challenges and Considerations

While the advantages of continuous carbon fiber are numerous, there are also challenges to consider. The cost of carbon fiber is higher than traditional materials, which can impact the overall expense of carbon fiber products. However, the long-term benefits often justify the initial investment, especially in high-performance applications where weight savings and durability are critical. Additionally, working with carbon fiber fabric and carbon fiber sheets requires specialized knowledge and equipment. Proper handling and curing techniques are essential to maintain the integrity of the carbon fiber sheets and the final carbon fiber product. Despite these challenges, the growing demand for carbon fiber solutions indicates a bright future for this advanced material.

The Future of Continuous Carbon Fiber

The future outlook for continuous carbon fiber is promising, with advancements in additive manufacturing techniques for continuous fiber-reinforced composites opening new possibilities for customized lightweight structures. Additionally, the development of low-cost carbon fiber precursors blended with traditional carbon fiber grades demonstrates the feasibility of scalable production for various applications, showcasing mechanical properties comparable to commercially available carbon fiber precursors. Furthermore, the invention of continuous carbon fiber composite materials with excellent heat-conducting properties through 3D printing techniques highlights the diverse applications and potential for high-heat conductivity materials.

Conclusion

Continuous carbon fiber is a revolutionary material that offers unparalleled strength, lightness, and versatility, making it essential for high-performance applications in various industries. Its unique properties, such as a high strength-to-weight ratio, corrosion resistance, and low thermal expansion, make it ideal for use in aerospace, automotive, sports equipment, construction, and beyond. Despite the higher costs and the need for specialized handling, the long-term benefits of continuous carbon fiber products often outweigh these challenges. As advancements in manufacturing techniques continue, the future of continuous carbon fiber looks bright, promising further innovations and broader applications. Whether in the form of carbon fiber fabric, carbon fiber sheets, or other carbon fiber products, this material is set to remain at the forefront of modern engineering and design.