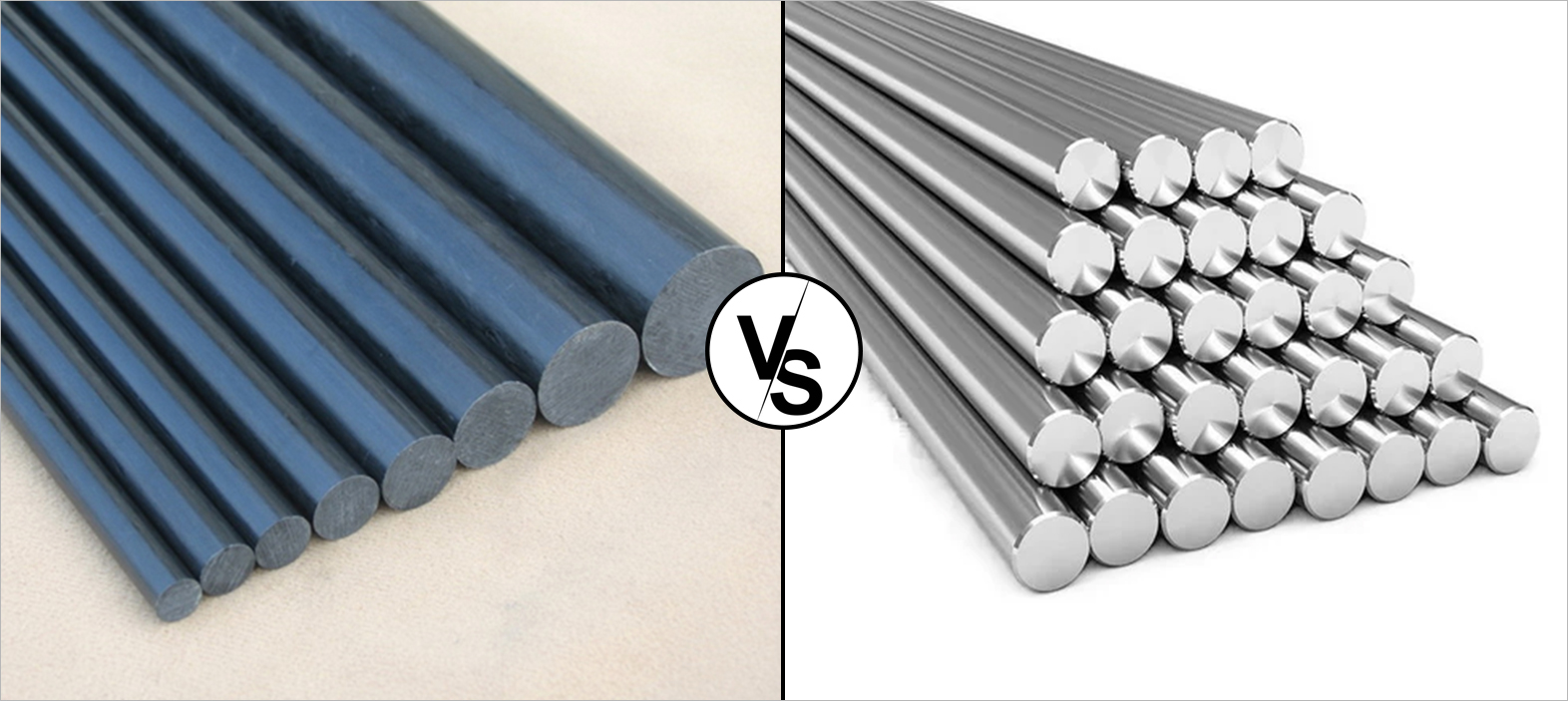

Carbon Fiber vs Steel: What's the Difference?

👁 Reads: 7957

When it comes to choosing the right material for a specific application, engineers and designers have to take into account various factors such as strength, weight, durability, and cost. Among the most common materials used in various industries are carbon fiber and steel, two materials with unique properties that make them suitable for specific applications. In this blog, we will explore the differences between carbon fiber and steel and their advantages and disadvantages.

Carbon Fiber: An Overview

Carbon fiber is a composite material that consists of thin strands of carbon woven together to create a fabric-like material. The strands of Carbon Fiber Products are made of carbon atoms bonded together in a crystalline structure that creates a strong and lightweight material. The carbon fiber is then impregnated with a polymer resin to create a composite material that has a high strength-to-weight ratio.

Carbon fiber is widely used in various applications, including aerospace, automotive, sports equipment, and industrial applications. It has several advantages over other materials, including high strength, low weight, and excellent fatigue resistance. Carbon fiber composites are also highly customizable, with different types of fibers, resins, and weaves available to create specific properties.

Steel: An Overview

Steel is an alloy made of iron and other elements, primarily carbon. It is one of the most commonly used materials in construction, manufacturing, and transportation due to its high strength, durability, and versatility. Steel is available in various grades, with different properties such as strength, ductility, and corrosion resistance.

Steel is widely used in various applications, including building construction, bridges, vehicles, and consumer goods. It has several advantages over other materials, including high strength, durability, and low cost. Steel is also highly recyclable, making it an eco-friendly choice for many applications.

Carbon Fiber vs Steel: Strength

Strength is a crucial factor in choosing the right material for an application. Carbon fiber composites have a high strength-to-weight ratio, which means they are stronger than steel per unit of weight. Carbon Fiber Products composites can have a tensile strength of up to 10 times that of steel, making them ideal for applications that require high strength and low weight.

Steel, on the other hand, has a high strength-to-density ratio, which means it is stronger than carbon fiber per unit of volume. Steel can withstand higher compressive loads than carbon fiber, making it ideal for applications that require high stiffness and rigidity.

Carbon Fiber vs Steel: Weight

Weight is another important factor to consider when choosing a material for an application. Carbon fiber composites are significantly lighter than steel, with a density of around 1.6 g/cm3, compared to steel's density of around 7.8 g/cm3. This means that carbon fiber composites can reduce the weight of a component by up to 70%, making them ideal for applications that require lightweight materials.

Steel is a relatively heavy material, which can add significant weight to a component. However, steel's high strength-to-density ratio makes it ideal for applications that require high stiffness and rigidity, such as building structures and heavy machinery.

Carbon Fiber vs Steel: Durability

Durability is a critical factor to consider when choosing a material for an application, as it can affect the component's lifespan and maintenance requirements. Carbon fiber composites have excellent fatigue resistance, meaning they can withstand repeated cycles of stress without experiencing fatigue failure. Carbon fiber composites are also highly resistant to corrosion, making them ideal for outdoor applications.

Steel is also a durable material, with excellent strength and fatigue resistance. However, steel is susceptible to corrosion, which can reduce its lifespan and require regular maintenance to prevent corrosion damage.

Carbon Fiber vs Steel: Cost

Cost is a crucial factor to consider when choosing a material for an application, as it can affect the overall project's budget. Carbon fiber composites are generally more expensive than steel due to their complex manufacturing process and high-quality materials. The cost of carbon fiber composites can vary widely depending on the type of fiber, resin, and manufacturing process used. However, the high strength-to-weight ratio and durability of carbon fiber composites can offset their higher initial cost by reducing the total cost of ownership over the component's lifespan.

Steel is a relatively low-cost material, with readily available raw materials and a simple manufacturing process. Steel's low cost makes it an attractive choice for many applications, especially those that require large volumes of material. However, steel's weight and susceptibility to corrosion can increase maintenance costs over time.

Carbon Fiber vs Steel: Applications

Carbon fiber and steel are used in various applications, each with unique properties that make them suitable for specific uses. Carbon fiber composites are widely used in aerospace, automotive, and sports equipment applications that require high strength and low weight. Carbon fiber composites are also used in industrial applications such as wind turbines, where their durability and fatigue resistance make them ideal for outdoor use.

Steel is widely used in construction and manufacturing applications that require high stiffness and rigidity. Steel is also used in vehicles, machinery, and consumer goods where its strength and durability are essential. Steel's recyclability and low cost make it an attractive choice for many applications, especially those that require large volumes of material.

Conclusion

In conclusion, carbon fiber and steel are two materials with unique properties that make them suitable for specific applications. Carbon fiber composites offer high strength, low weight, and excellent fatigue resistance, making them ideal for aerospace, automotive, and sports equipment applications. Steel offers high strength, durability, and low cost, making it suitable for construction, manufacturing, and transportation applications. When choosing between carbon fiber and steel, engineers and designers must consider various factors such as strength, weight, durability, and cost to select the right material for the application.