Tips and Tricks for Keeping Your Carbon fiber in Good Shape

👁 Reads: 1018

The carbon fibers, when placed side by side parallel to each other with a resin present between the layers, form a sheet—these sheets, when joined from both edges, form a tube with a hollow area. If the hollow areas are filled with fibers and resins at a constant distance, it forms a rod. All these products vary in thickness, diameter, and area. The volume of rods is maximum as they contain more fibers than sheets and tubes.

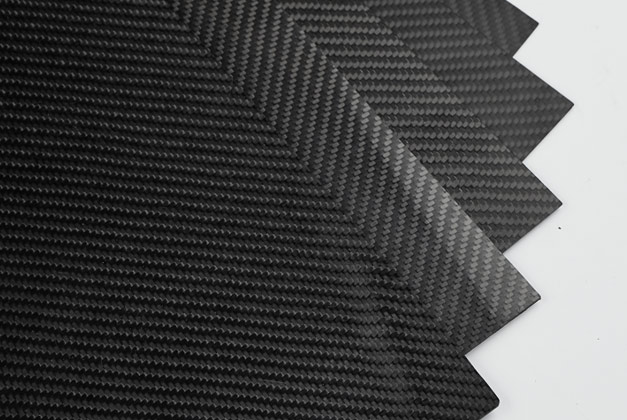

Carbon fiber sheets mainly consist of two components: carbon fibers and resin matrix. It is infused with epoxy resin to form sheets. It is then cured to become rigid. The sheets are available in different sizes and thickness. Increasing the plies of fibers offers better strength. The sheets are used for lightweight applications in strong medical devices and prosthetics. The high strength-to-weight ratio of carbon fiber makes it worthwhile in the automotive sector, aerospace industry, construction sector, drones, robotics, and many other applications. The automotive world is obsessed with lightweight materials. From 1981, the utilization of carbon fibers in the chassis of McLaren MP4/1 Formula One racing cars.

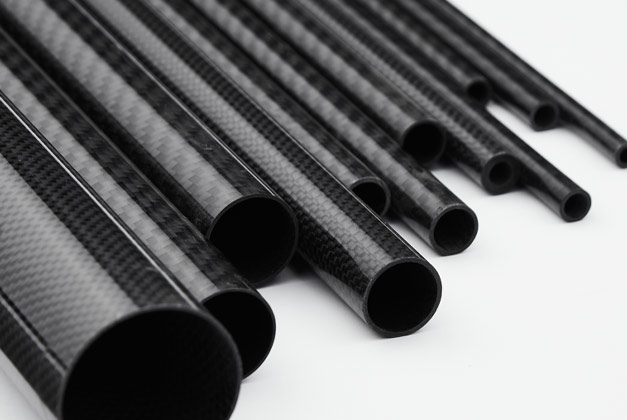

Carbon fiber tubes are cylindrical structures made from carbon fiber-reinforced polymer. Thin, flexible carbon fiber filaments are embedded in the polymer matrix. It is then wound or laid up in a cylindrical shape and is cured under heat and pressure to form carbon fiber tubes. It can be made in any shape virtually. Carbon fiber tube is 1/3rd of an aluminum tube but offers the same or better strength. Roll-wrapped carbon fiber tubes are formed using multiple wraps of twill or unidirectional fabrics. Carbon fiber tubes are suitable for applications where high bending stiff and low weight. Braided carbon fiber tubes are made up of carbon fiber braid and unidirectional fibers. It offers excellent torsional characteristics and is used in high-torque applications. The stiffness of tubes can be increased by using a higher modulus of fibers. They can also be axially optimized. It requires surface treatment. It can be treated with cello-wrapped, or peel ply is applied. The tubes are widely used in luxury vehicles to drive shafts, which helps to reduce rotational mass. These tubes are incorporated in high-end fishing rods due to their strength and flexibility. They can vary in terms of diameter, length, wall thickness, and fiber orientation depending upon specific application. Due to their strength-to-weight ratio, carbon fiber tubes are used to manufacture prosthetic limbs.

Carbon fiber rod is an excellent choice for applications where stiffness and lightweight properties are significant concerns. The rods are 1/3 the weight of comparable aluminum rods. The rods are manufactured by the pultrusion process. The fibers are mixed with epoxy resin and are pulled through heated forming dies. Axial strength and limitless length are obtainable. The rods are widely used to create construction frames. Being lightweight and strong, they have replaced steel and aluminum rods. They are basic building blocks for many structures. Researchers in the construction industry are continuously trying to adopt improved materials for sustainability. They are corrosion-resistant and can be utilized in exposed environments, which is a replacement for metallic and steel structures that are susceptible to corrosion.

Tips to keep carbon fibers in good shape:

Preventing damage to carbon fibers is highly important to ensure longevity and maintain product quality. Proper care is required to maintain its optimal condition. Here are some tips and tricks to keep carbon fiber in good shape:

Cleaning:

Dirt and dust should be removed from carbon fibers. This can be done by cleaning carbon fibers with warm water or wiping them with a soft cloth. Water should not be allowed to dry on the surface of carbon fiber. It will damage the clear coat of fibers. Microfiber towel is preferred to dry water because it will prevent scratches and swirls. Abrasive materials should be avoided for cleaning carbon fibers to prevent scratches or scars.

Cleaning with mild detergents:

Mild detergent can be used to keep the carbon fiber in good shape. After using detergent, carbon fibers are thoroughly washed with water.

Protection from Ultra Violet Radiations:

Prolonged exposure to sunlight or ultraviolet rays will damage carbon fibers. Carbon fiber products are stored away from sunlight. Normally, ultraviolet protective coatings are used for UV protection on carbon fibers.

Avoid acids and harmful chemicals:

Acids and harmful chemicals should be avoided to keep carbon fibers in good shape. These chemicals can result in damage to the resin and carbon fibers. They also affect the final finish or aesthetic appearance of fibers. Neutral pH chemicals should be preferred in this regard.

Impact prevention:

Carbon fiber has high strength, but it is prone to crack upon Hard impact. A hard impact can initiate cracks in carbon fiber. Handle the carbon fibers carefully. Avoid dropping or hitting carbon fiber against hard surfaces to prevent cracking.

Inspection of carbon fibers:

Carbon fiber items should be inspected regularly. Cracks, delamination, or dislocation should be identified and addressed timely to avoid catastrophic failure.

Storage:

Carbon fibers should be stored in a clean and dry environment for later use. Severe atmospheric conditions should be avoided. Extreme temperature and humidity should be taken into account while storing carbon fibers.

Appropriate use of lubricants:

Lubricants are used to prevent wear and tear of components. Moving parts of machines or vehicles made up of carbon fibers should be lubricated to avoid excessive heat generation due to friction. Appropriate lubricants designed for specific applications should be used to prevent wear and tear of carbon fiber moving parts.

Edge protection:

Edges are more vulnerable to damage. Carbon fiber products having sharp edges demand extra protection for edges to prevent damage. Edge protectors or guards can be used to avoid edge damage.