Why Epoxy Resin Is Used In Manufacturing Carbon Fiber Products?

👁 Reads: 395

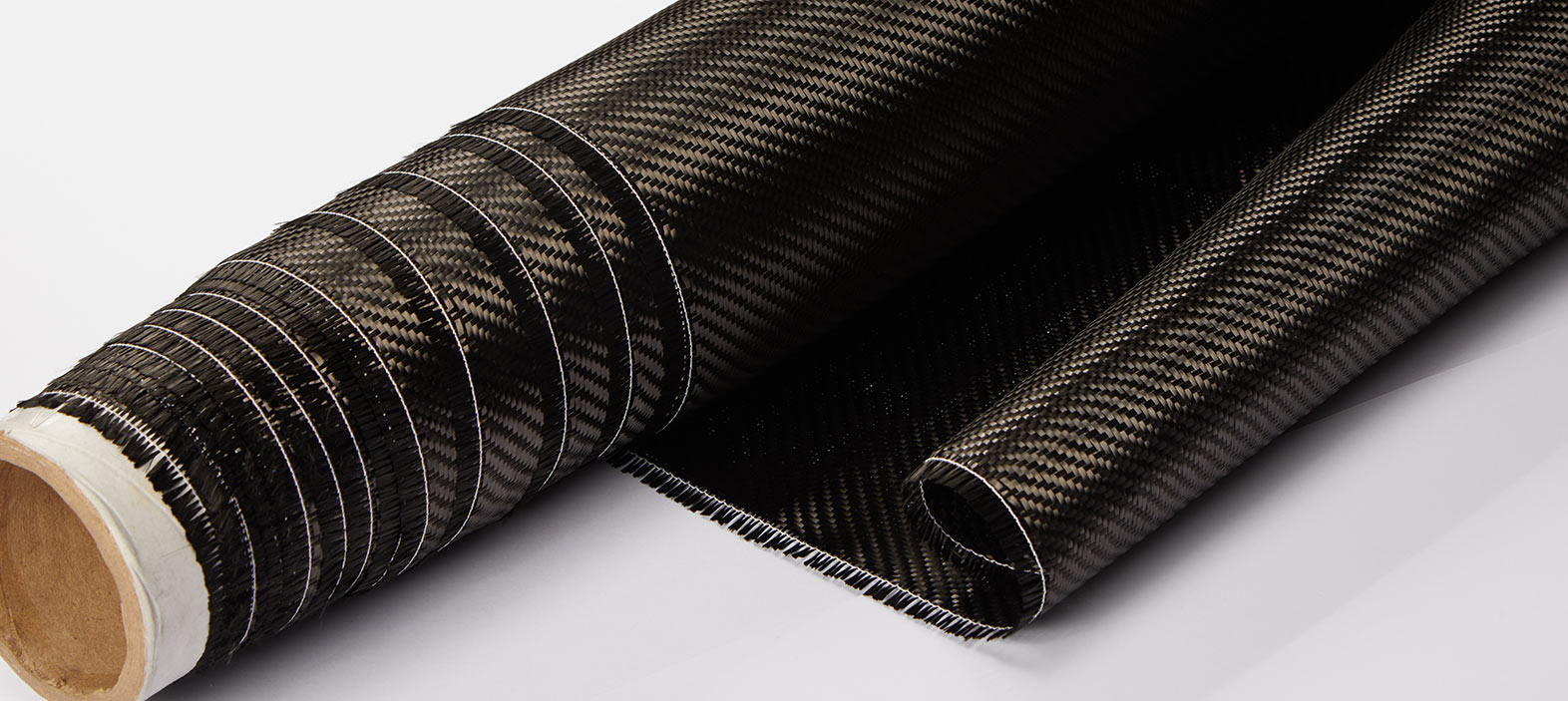

Carbon fiber is one of the most versatile and durable materials used in the manufacturing of a wide range of products. It is lightweight, strong, and resistant to corrosion, heat, and chemical damage. However, to ensure that carbon fiber products are able to withstand extreme temperatures and conditions, manufacturers often use epoxy resin.

Epoxy resin is a key material used in the manufacturing of carbon fiber products. It is an essential component in the production of composite materials, as it provides strength, rigidity, and durability to the finished product. Epoxy resin is a type of polymer that is used for adhesives, coatings, and for forming strong bonds between materials. This makes it ideal for use in the production of the lightweight, high-strength material. Carbon fiber is a type of material that is extremely lightweight and strong, yet also flexible and resilient. To produce a strong and durable product using carbon fiber, epoxy resin is essential.

Here are the top 10 reasons why epoxy resin is used in the manufacturing of carbon fiber products:

1. It Enhances Strength and Durability

Epoxy resin enhances the strength and durability of carbon fiber. This is because the resin forms a strong bond with the fibers, which makes the product more resistant to cracking, chipping, and other forms of wear and tear.

2. It Increases Resistance to Corrosion

This material is also used in the manufacturing of carbon fiber composites products because it increases their resistance to corrosion. The chemical bond prevents corrosion caused by water, chemicals, and other elements.

3. It Increases Resistance to Heat

Yes, this is true that it increases the resistance of carbon fiber to heat. This is because the resin acts as an insulator, preventing the product from heating up too quickly and becoming damaged.

4. It Increases Resistance to Chemicals

Epoxy resin is also used in the manufacturing of carbon fiber tubes because it increases their resistance to chemicals. The chemical barrier formed helps in prevention of further damage.

5. It Improves Adhesion

Epoxy Resin improves adhesion. This is because the resin forms a strong bond with the fibers, which prevents the product from coming apart.

6. It Improves Moldability

In the manufacturing of carbon fiber rods and other products, epoxy resin helps in improving the moldability. Resin softens the fibers, making them easier to shape and form into different shapes and sizes.

7. It Reduces Weight

The resin is lightweight, meaning that the product will be lighter overall.

8. It Increases Design Flexibility

Epoxy resin can be used to create complex shapes and sizes, which can be used to create unique designs.

9. It is Cost-Effective

It is relatively inexpensive compared to other materials, making it a great choice for manufacturers looking to reduce costs.

10. It is Environmentally Friendly

Epoxy resin is environmentally friendly and does not contain any toxins or harmful chemicals, making it a great choice for those looking to reduce their environmental footprint.

Overall, epoxy resin is an ideal choice because of its strength, durability, and affordability. It is capable of forming a strong bond between two objects, providing superior protection against wear-and-tear, and offering superior adhesion and resistance to corrosion. Its light weight also makes the resin an ideal choice to buy carbon fiber products and the production of lightweight products. With its many benefits, it is clear to see why epoxy resin is a popular choice for the manufacture of carbon fiber products.