How Durable and Reliable Is CFRP?

👁 Reads: 504

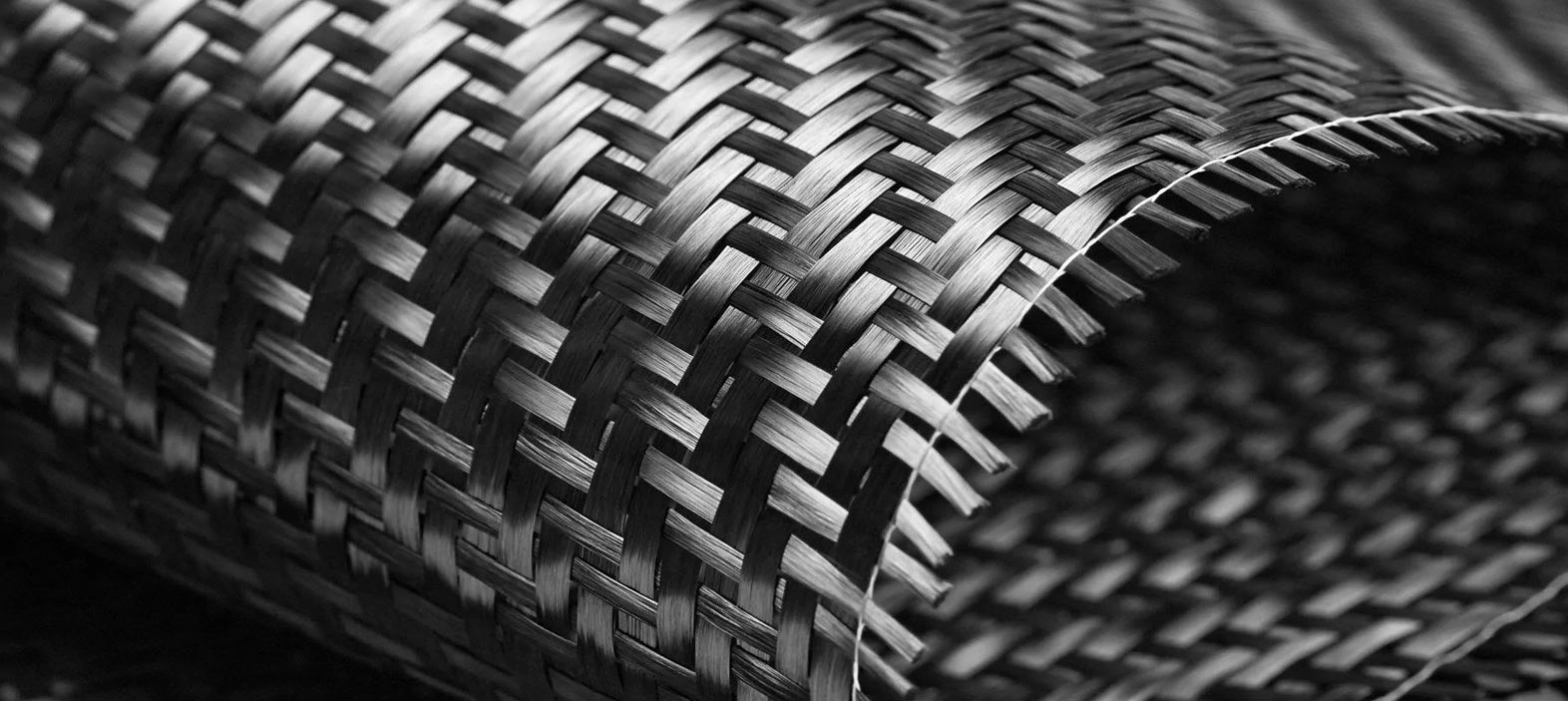

Carbon fiber reinforced polymer (CFRP) is a strong and light composite material that has been used in a variety of applications over the past several decades. It is made up of a combination of carbon fibers and polymer resin, which when cured together create a strong and lightweight material. CFRP has a unique combination of properties that make it ideal for a variety of applications, from structural components to aerospace and automotive components.

Reasons Why CFRP Is Known for Being Durable and Reliable

There are many reasons why CFRP is known for being durable and reliable. CFRP is a composite material made from carbon fibers embedded in a polymer matrix. This results in a lightweight but very strong material. It is used in many aerospace and automotive components, from the fuselage and wings of planes to the body panels of cars. It is also used in the manufacture of industrial components such as structural supports, pultruded carbon fiber rods, piping, and airframe components.

Carbon Fibers Used in CFRP Are Incredibly Strong

The first is that the carbon fibers used in CFRP are incredibly strong. Carbon fiber sheets are five times stronger than steel, yet weigh only one-fifth as much. This makes it a very attractive choice for applications where weight is a limitation. In addition, the polymer resin used with CFRP is also extremely strong and resistant to corrosion. This combination of strength and corrosion resistance makes it an ideal material for components that need to withstand harsh environments and extreme temperatures.

Superior Strength to Weight Ratio

CFRP is incredibly strong and durable, offering superior strength to weight ratio compared to other materials. It is resistant to bending and twisting, making it ideal for use in structural components and other applications that require stiffness and strength like customized carbon fiber rods. It also has excellent fatigue resistance, meaning it will not crack or break under repeated stress, making it a great choice for components that must withstand constant usage.

Very Corrosion-Resistant

CFRP is also very corrosion-resistant. It has excellent chemical resistance, meaning it can withstand exposure to harsh chemicals without degrading. This makes it an ideal material for components that are exposed to harsh conditions, such as those found in the aerospace and automotive industries. Its excellent temperature tolerance makes it suitable for both hot and cold environments.

High Fatigue Resistance

Another benefit of CFRP is its high fatigue resistance. This means that it has the ability to withstand repeated cycles of stress without failure. This is due in part to the high quality of the carbon fibers used, as well as the strength of the polymer resin. This makes CFRP an ideal choice for components that will be subject to continuous stress and strain.

Ability to Resist Shock and Vibration

Another factor that contributes to the durability and reliability of CFRP is its ability to resist shock and vibration. CFRP has a low coefficient of thermal expansion, which means that it is not affected by sudden changes in temperature. This makes it ideal for components that must be able to withstand extreme temperatures and other environmental conditions.

Low Maintenance Requirements

Finally, CFRP is also known for its low maintenance requirements. Since CFRP does not corrode or rust, it can be used in parts without the need for regular maintenance. This makes it a great choice for applications that require a durable and reliable material without the hassle of frequent maintenance.

Summing up

In conclusion, CFRP is one of the most reliable and durable materials available today. It combines the strength of carbon fibers with the resistance of polymer resins to create an incredibly strong and lightweight material. It has high fatigue and corrosion resistance, as well as excellent shock and vibration resistance, making it ideal for a variety of applications. In addition, its low maintenance requirements make it a great choice for components that must withstand extreme environmental conditions without frequent maintenance. For these reasons, CFRP is often the material of choice for a variety of components, from structural components to aerospace and automotive components.