Understanding 3K Carbon Fiber Tubes: Strength and Versatility in Engineering

👁 Reads: 580

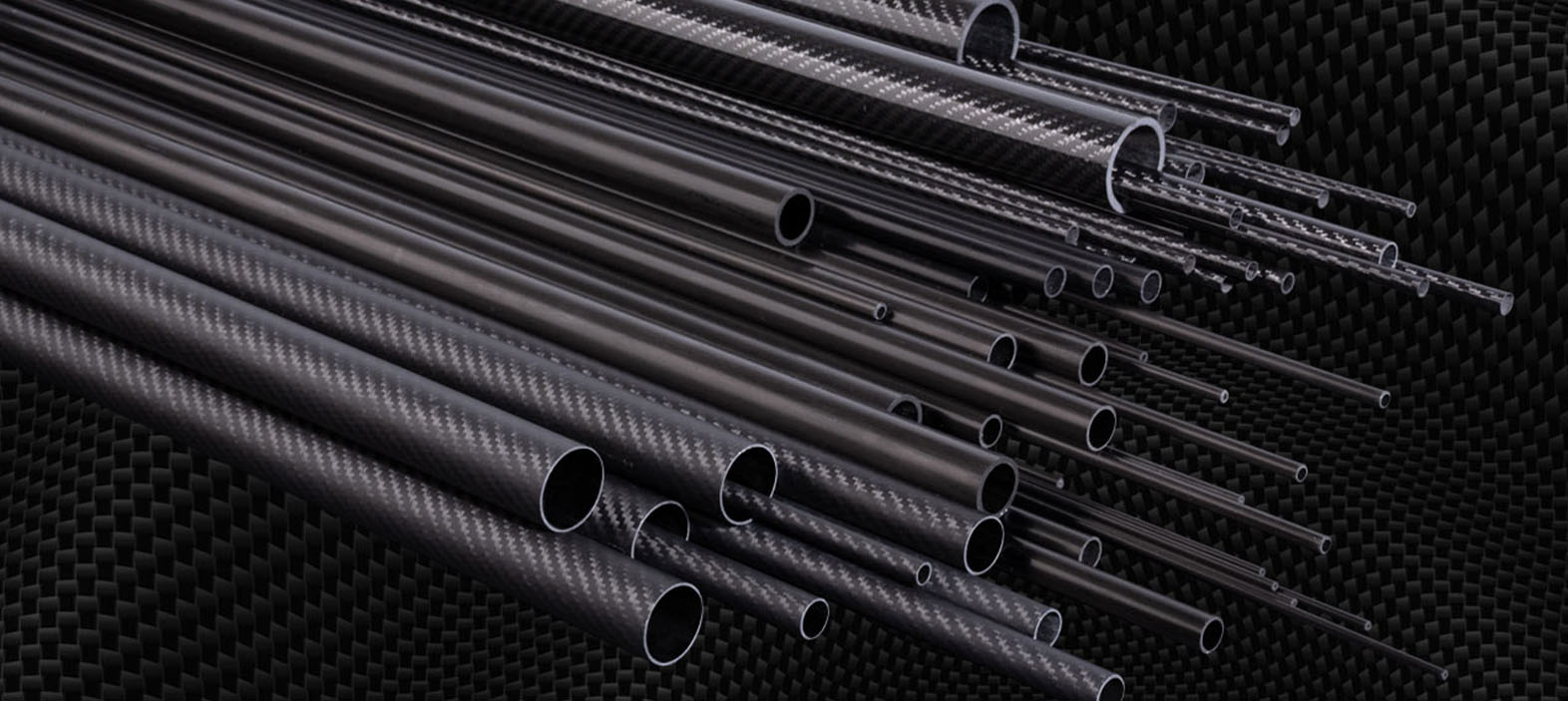

Carbon fiber composites have revolutionized the aerospace, automotive, and sporting industries due to their exceptional strength-to-weight ratio. Among the various products, the 3K carbon fiber tube is a versatile component with applications in diverse fields. This article will explore the features, manufacturing process, and applications of 3K carbon fiber tubes, shedding light on their remarkable properties and benefits.

Understanding Carbon Fiber

Carbon fiber is a composite material consisting of thin, strong fibers made primarily from carbon atoms. In this process, the fibers are bound together by a polymer matrix, resulting in a material that is both lightweight and incredibly robust. The composites offer superior mechanical properties, including high tensile strength, stiffness, and excellent resistance to corrosion and fatigue.

The Significance of "3K"

The term "3K" refers to the weave pattern, specifically the number of individual filaments bundled together. In a 3K carbon fiber tube, "3K" denotes 3,000 carbon filaments grouped together within a single tow. The K represents the prefix "kilo," which means a thousand. The higher the K value, the greater the number of individual filaments within a tow, resulting in increased strength and stiffness.

Manufacturing Process

The manufacturing process involves several steps:

- Material Selection: High-quality yarns are carefully selected, considering their tensile strength, modulus, and other required properties.

- Prepreg Production: To create prepreg sheets, the selected yarns are impregnated with a thermoset resin, usually epoxy. These prepreg sheets offer precise control over fiber alignment and resin distribution.

- Layup and Curing: The prepreg sheets are cut into specific dimensions and stacked layer by layer in a mold, aligning the fibers according to the desired pattern. The assembly is then cured under heat and pressure, transforming the prepreg into a solid structure.

- Post-processing: Once cured, the tubes undergo various post-processing steps, such as sanding, trimming, and surface treatment, to achieve the desired final dimensions, smoothness, and appearance.

Unique Properties of 3K Carbon Fiber Tubes

3K carbon fiber tubes possess several unique properties that make them highly desirable in various applications:

- High Strength-to-Weight Ratio: The 3K carbon fiber's arrangement of 3,000 filaments in each tow provides exceptional strength while maintaining a lightweight profile. This property is crucial in industries where weight reduction is essential, such as the aerospace and automotive sectors.

- Excellent Stiffness: The aligned fibers provide high stiffness, ensuring minimal deflection under load. This property makes them ideal for applications that require rigidity and stability, such as robotics and industrial equipment.

- Corrosion and Fatigue Resistance: Carbon fiber composites, including 3K carbon fiber tubes, exhibit excellent resistance to corrosion and fatigue, making them suitable for outdoor and demanding environments.

Applications of 3K Carbon Fiber Tubes

Their versatility enables their use in various industries:

- Aerospace: Are employed in aircraft structures, including wing spars, fuselage frames, and control surfaces. Their lightweight nature contributes to fuel efficiency and improved performance.

- Automotive: These tubes find applications in high-performance automotive components like suspension systems, driveshafts, and roll cages. The strength and rigidity enhance the overall structural integrity and reduce vehicle weight.

- Sports and Recreation: Their lightweight and strong nature make them popular in sporting equipment, such as bicycle frames, fishing rods, and archery bows. They also offer enhanced performance and increased manoeuvrability.

- Industrial Applications: the utilization is also done in robotics, automation, and machinery, where their strength, stiffness, and corrosion resistance contribute to overall efficiency and durability.

- Medical and Rehabilitation Devices: The tubes are employed in the manufacturing of prosthetics, orthopedic supports, and rehabilitation equipment. The lightweight and customizable nature of carbon fiber tubes facilitates better patient mobility and comfort.

Conclusion

The remarkable properties of 3K carbon fiber tubes make them indispensable in numerous industries, from aerospace to sports and beyond. Their high strength-to-weight ratio, excellent stiffness, and corrosion resistance contribute to improved performance, reduced weight, and enhanced durability. As technology advances and manufacturing techniques improve, we can expect further advancements in carbon fiber composites, pushing the boundaries of what is possible in engineering and design. The future holds immense potential for 3K carbon fiber tubes as they continue to revolutionize various sectors and pave the way for lightweight, strong, and sustainable solutions.