Weave Patterns in Carbon Fiber Fabric: Which One Should You Use?

👁 Reads: 490

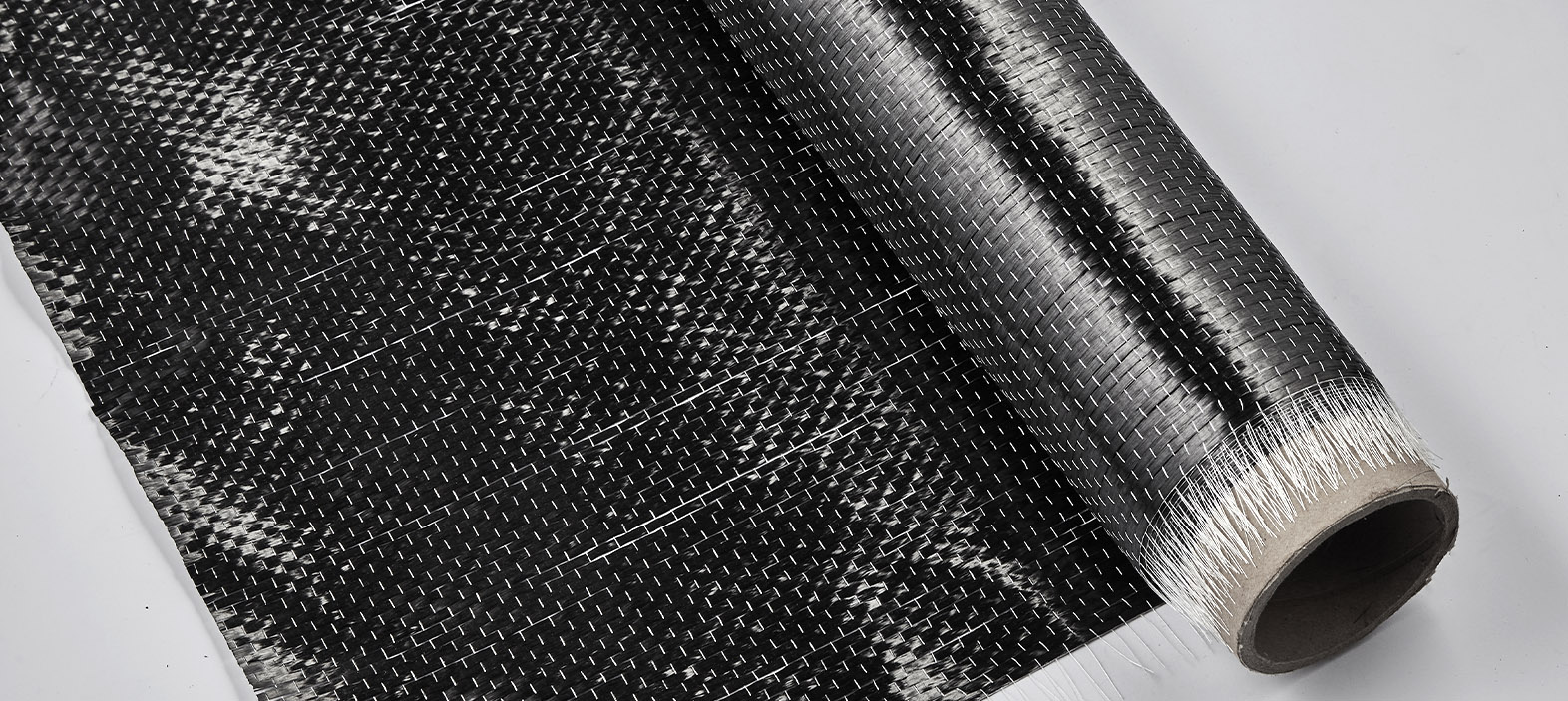

Carbon fiber is renowned for its strength, lightweight nature, and versatility, making it an essential material in industries like automotive, aerospace, sports, and even consumer electronics. While the material itself is often the focal point of attention, the weave pattern in carbon fiber fabric plays an equally crucial role in determining the properties and performance of the final product. From the traditional plain weave to the more intricate twill and satin weaves, understanding the different weave patterns is essential when choosing the right fabric for a project. In this blog, we’ll explore the various carbon fiber weave patterns and provide guidance on which one to choose based on your specific application.

What Are Weave Patterns in Carbon Fiber Fabric?

Weave patterns refer to the way individual carbon filaments are arranged in the fabric. The arrangement affects both the appearance and the mechanical properties of the material, including its strength, flexibility, and drape. The most common weave patterns in carbon fiber fabrics are plain weave, twill weave, and satin weave, with each offering unique benefits suited to specific applications.

1. Plain Weave Carbon Fiber Fabric

The plain weave is the simplest and most basic weave pattern. In this structure, the carbon fibers alternate over and under each other in a consistent grid pattern, creating a checkerboard-like appearance. Plain weave fabrics are known for their even distribution of stress and good dimensional stability, which makes them ideal for flat and relatively simple applications.

Advantages of Plain Weave:

- Durability: The interlaced structure gives the fabric a high level of durability and resistance to damage from abrasion.

- Ease of Use: Plain weave fabrics are easier to handle and cut, making them a popular choice for beginners and in mass production.

- Cost-Effective: Due to its simplicity, plain weave fabrics are often less expensive than more complex weave patterns.

Plain weave carbon fiber fabric is commonly used in products that require strength without complex shapes, such as flat panels, automotive parts, and aerospace components.

2. Twill Weave Carbon Fiber Fabric

The twill weave is another popular choice, characterized by a diagonal pattern created by passing the fibers over and under two or more filaments at a time. This results in a fabric that is more flexible and softer than plain weave. The 2x2 twill weave is the most common variation, where each fiber crosses over two others, creating a distinct diagonal pattern.

Advantages of Twill Weave:

- Enhanced Flexibility: Twill fabrics drape more easily around curves and complex shapes, making them ideal for molding and forming in custom parts.

- Better Aesthetic Appearance: The diagonal pattern is visually appealing and often used in high-end products where the appearance is as important as performance.

- Increased Strength: Twill weave provides better impact resistance and is more resilient to external forces compared to plain weave fabrics.

Due to its flexibility and strength, twill weave carbon fiber is commonly used in applications such as motorcycle body panels, sports equipment, and automotive parts that require both performance and aesthetics.

3. Satin Weave Carbon Fiber Fabric

Satin weave fabrics, often called basket weave or satin finish, involve a more complex arrangement where multiple fibers pass over and under others, creating a smooth, lustrous surface. Satin weave typically results in a more shiny, polished look compared to other patterns, making it a preferred choice in high-end applications where appearance matters.

Advantages of Satin Weave:

- Smooth Surface: The smooth surface is perfect for applications where the surface finish is critical, such as in high-end consumer electronics or aerospace components.

- High Strength-to-Weight Ratio: While being more flexible, satin weave fabrics also maintain excellent strength and are lighter than other patterns.

- Enhanced Conformability: Satin weave is especially useful in applications where the fabric needs to conform to intricate and curved surfaces.

Satin weave carbon fiber is often used in luxury automotive components, high-performance sporting goods, and aircraft parts where both strength and visual appeal are critical.

Choosing the Right Weave for Your Project

The choice of weave pattern should depend on the specific demands of your application. Here are some factors to consider:

- Complexity of the Part: If you’re dealing with complex or highly contoured shapes, twill or satin weave fabrics are often the best choice. Their flexibility allows them to mold around curves with ease.

- Strength Requirements: If maximum strength and durability are essential, plain weave is a reliable option. However, twill and satin weaves also offer robust performance, especially under high-impact conditions.

- Cost Considerations: Plain weave is generally the most affordable option, while satin and twill weaves tend to be more expensive due to their complexity.

Weave patterns in carbon fiber fabric are not just a matter of aesthetics; they play a crucial role in determining the mechanical properties and performance characteristics of the final product. Whether you choose plain weave for its strength and cost-effectiveness, twill weave for flexibility and a refined appearance, or satin weave for its smooth, glossy finish, understanding the differences between these patterns can ensure that you select the right material for your specific needs.