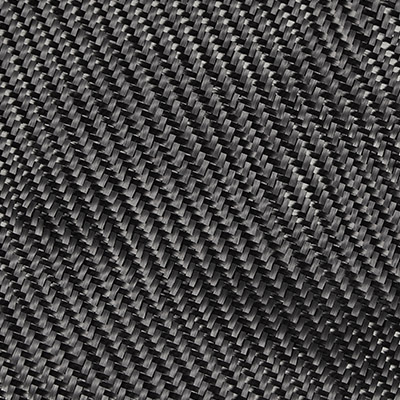

What is forged carbon fiber?

👁 Reads: 549

Unlike woven carbon fibers which consist of regular weaves, forged Carbon fibers are made from small chopped Carbon fiber elements which are scattered across the volume of the material leaving irregular pattern and direction. The finished material’s surface can have looks of chipped marble floor tiles and many other varieties.

Manufacturing process:

The process of making forged carbon fiber is similar to the process of metal forging.

Pieces of chopped carbon fibers or of woven fibers are scattered across a mold wherein resin is impregnated and then this mold is compressed using a power press. The fiber pieces are placed in multi-direction orientations providing 3D strength. Thereafter, it is heated to stimulate the chemical reactions by curing and hardening.

After completion of the curing process, the molded component is removed from the mold and undergoes finishing processes like chamfering, trimming, surface-treatment, and polishing depending on the application.

Forged carbon fibers can be produced in the form of fabrics or prepregs (pre-impregnated layers) depending on the end use. To make the prepregs, we use carbon fabrics and Infuse resins in a proper proportion based on desired properties. Prepregs need to be stored at low temperatures.

Carbon fiber sheets can also be fused with fibers that are chopped, to produce a composite fabric material. It is easier to make components using forged Carbon fiber as compared with woven Carbon fiber.

Modular blocks of forged carbon fiber are also made for building desired products needing high stiffness.

Companies are these days offering packets of chopped loose carbon fibers or billets to users who make forged carbon fiber products.

Advantages of forged carbon fiber composites:

- With a high fiber content, a component made from forged carbon fibers may be stronger than titanium, but much lighter in weight due to density being less than half of titanium

- As the fiber pieces are relatively free, it is possible to mold the composites into complex geometries to address the requirements in the automotive and formula one industry

- Specific compositions can be created to make molded blocks machinable to achieve further shapes and contours which may be found challenging in molding. Drilling, turning milling, engraving, and tapping operations on carbon fiber composites are now a reality

- Random spread of fiber pieces makes the resulting products having unusual isotropic properties which offer further benefit in various applications

- Carbon fibers are also combined with glass fibers and chopped strands and pieces to create decorative aesthetics on surfaces of useful items.

- Sharp curves, corners and minute holes are easy to build

- Being one-fifth by weight of steel for a given volume, and having high thermal resistance, it replaces critical components which were traditionally made from steel, like automotive hoods, panels, and exhaust manifolds.

- Waste and left over carbon fibers pieces can also be used in the process

- These have lower costs as compared to other similar raw materials

Applications:

Sports cars use a variety of carbon fiber composites including forged carbon fiber composites. Typical examples are monocoque chassis, suspension and seat supports (primarily, structural components). Lamborghini concept cars have been using such materials, often.

Aerospace industry has been a traditional beneficiary of all variety of carbon fiber products.

Metrology and laser alignments in engineering industry use forged carbon fiber blocks due to accuracy of dimensions and surfaces. For instance, for rendering better measurements, granite blocks are being replaced by carbon fiber composite blocks.

Being light and highly well moldable, they also find use in sporting equipment like golf and tennis.

Due to refined aesthetics, non-corrosive, skin-safe, lowest coefficient of thermal expansion, high dimensional accuracy and water-proof properties, the following additional lifestyle applications are ongoing:

- Luxury watches is another niche application of forged carbon fiber products

- High end mobile phone components and related accessories

- Premium writing instruments

- Ornaments and jewelry like rings, pendants, bands and necklaces

- Ladies’ accessories like hand-bag logos and decorative panels

- Acoustics based on the sound insulation properties

Wrapping up:

In view of the illustrated advantages and high-performance properties of forged carbon fiber products, they are fast transforming traditional metal forging industry in select applications helping inventors create wealth and benefit society at large.

In the coming years the forged carbon fiber products will further evolve with more and more applications which could be relevant for the sustainable development goals as well.