Why are carbon fiber laminates used to strengthen conventional structural materials?

👁 Reads: 1007

Materials made by using thermosetting resins reinforced with carbon fiber strands or Carbon fabrics are the new age raw materials used in a wide range of applications. Thanks to the superlative physical properties, no wonder, the buzzword in the structural engineering industry is CFRP (composite fiber reinforced polymers).

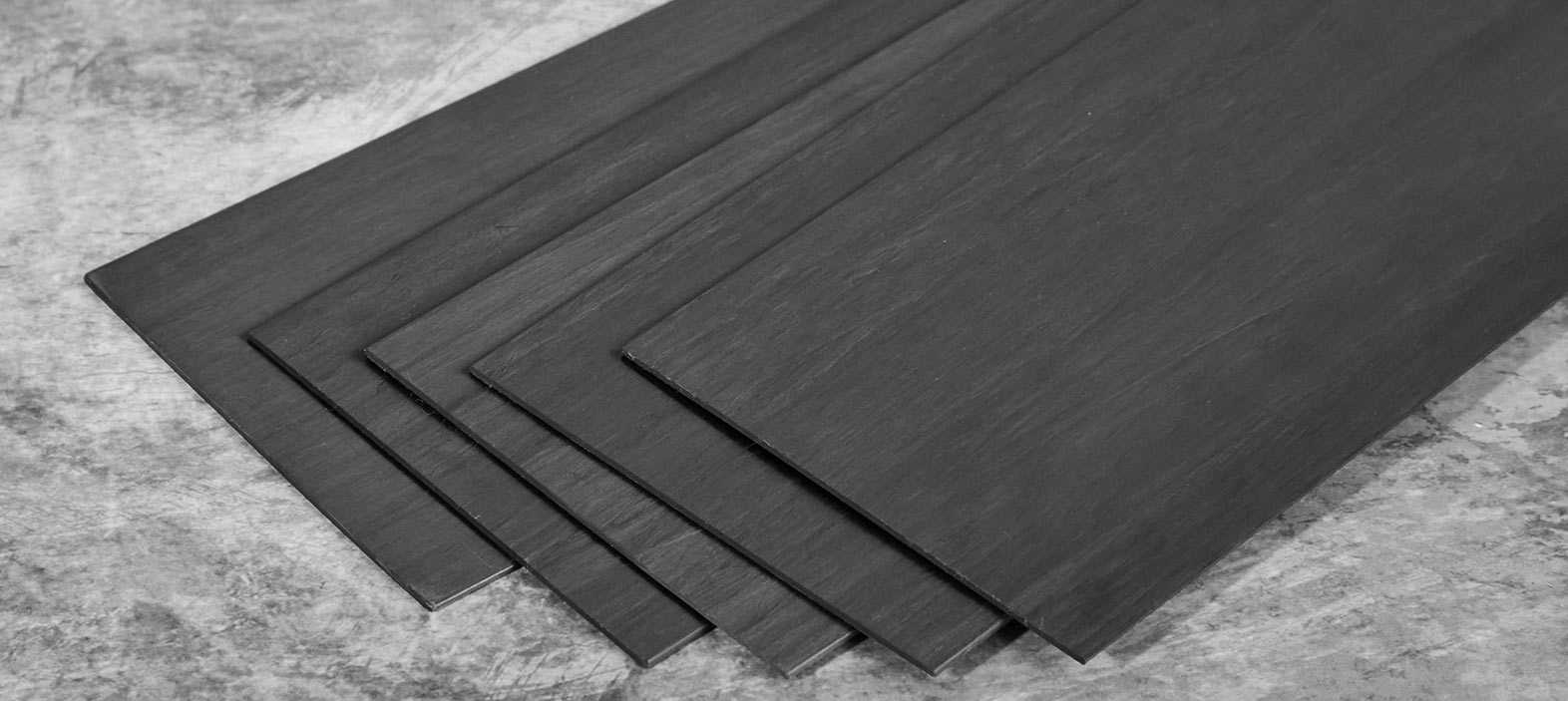

One of the important members in the CFRP family is carbon fiber laminates. The process of lamination of carbon fibers can be either by hand laying, which is easy, basic low-cost but high-skill method, or by pultrusion which is another popular technique that results in higher tensile strength.

The possibility of customization of physical properties of carbon fiber laminates in advance, during design, using skills and software is of immense advantage. This is in line with the fast-paced advancements in almost every scientific field, be it basic sciences, research, or high-end process equipment.

Thanks to the support from the IT industry, specific software are now available to help design Carbon fiber laminates for strengthening of structural members to achieve targeted properties for specific applications.

Composite fiber laminates are widely used in strengthening of conventional materials like timber, concrete, prefabs and Steels that are used in structural applications.

Properties and Advantages

Let us now look at the properties of the Carbon Fiber Laminates and the relevant advantages accruing therefrom:

- Lightweight in comparison with conventional materials like structural Steels makes them easier to transport to, and lift at construction sites or installation sites

- Superior strength to weight ratio results in reduction in self-weight of structures wherein composite fiber laminates have been used. Thanks to availability of software that enable calculate in advance, the savings in self-weight

- Higher flexural strength makes them suitable for use in members used for long horizontal supports

- Great corrosion resistance renders them ideally useful for chemical industry applications

- Longer shelf life means no worries of deterioration during warehousing

- Unaffected by wide range of temperatures make them fit for use in extreme climate conditions and hazardous environments besides Aerospace applications

- Higher dimensional stability and poor thermal conductivity are further reasons for suitability in various applications wherein weathering effects are detrimental to the life of structures

- Due to easy formability, it is possible to form complicated shapes of components

Other High Technology applications:

- Being non-magnetic, carbon fiber laminates find special use in high end physics-based equipment

- High impact resistance ballistic protection shields use laminated carbon fiber composites to protect soldiers against bullets during war

- Another special military application is in the making of quick-shelters that are required to house soldiers in adverse working areas. Light weight of carbon fiber laminates makes them easier to transport to difficult areas via rough terrains at lower costs.

- Defense communication equipment like advanced antennae and radars can be installed faster using carbon fiber laminate support members

Field of Civil Engineering:

Civil engineering Constructions, and particularly, structural engineering constructions like elevated Metro ways and bridges involve lot of use of Steel reinforcement cables which are being fast replaced by pultruded carbon fiber cables and laminated carbon fiber. Besides cables, steel is used in other forms like bearing plates which also are replaceable by carbon fiber laminates.

Another favorable aspect is that carbon-fiber-based composites are glue-able to concrete slabs after proper preparation of surfaces and thereafter, the laminates need to be treated with a pressing roller tool to eject excess of glue/resin. The failure of reinforcement Steel in concrete bridges is commonly reported due to corrosion of Steel but with laminated carbon fiber, this problem gets eliminated.

Technical facts:

- Carbon fiber laminates can be built layer on layer manually based on the fiber direction to achieve desired strength

- Stiffness of carbon fiber laminates is a product of modulus and ply thickness

- Particular orientation of fibers results in desired strength in certain applications in scientific equipment

- Applications like quantum physics involve high temperatures that carbon fiber laminates can easily withstand

- High typical tensile strength of > 2800 MPa with an extension within 0.5 % compared with just 500 MPa tensile strength and 2.5% extension in steel