Acrylic Resin vs. Epoxy Resin: Choosing the Ideal Companion for Your Carbon Fiber Products

👁 Reads: 928

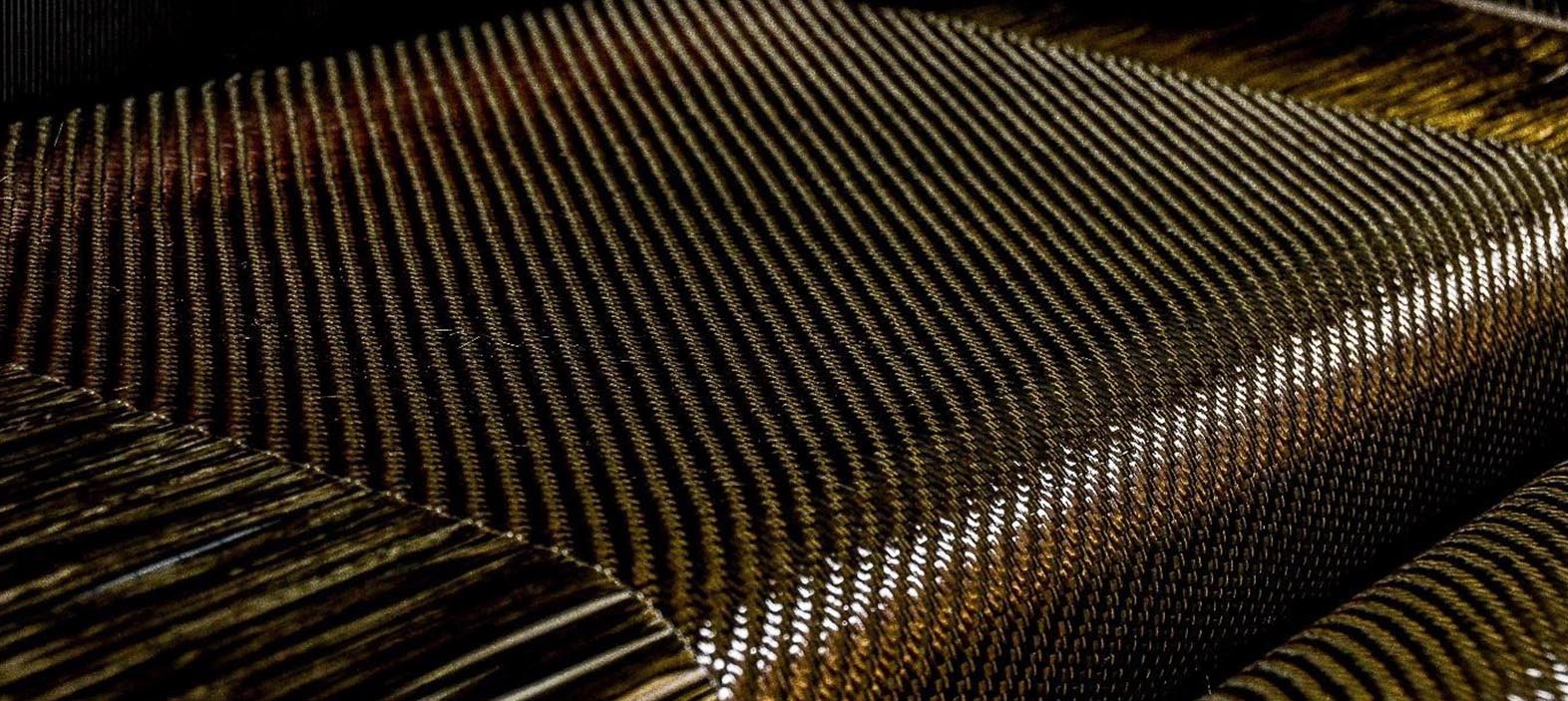

In today's fast-paced world of manufacturing, carbon fiber has emerged as a game-changer. Its lightweight yet durable characteristics make it a desirable material in a variety of sectors. However, the journey from raw carbon fiber to a finished product often involves an essential decision: which resin to use, acrylic or epoxy? In this blog post, we'll explore the differences between these two resins, highlighting their roles in crafting top-tier carbon fiber products.

The Role of Resins in Carbon Fiber Products

Before we get into the acrylic vs. epoxy discussion, it's important to understand the role of resins in the manufacturing of carbon fiber products. Carbon fiber alone does not have the binding power to form into complex shapes or structures. Resins act as the glue that binds carbon fibers together, creating the composite materials used in various applications.

Acrylic Resin: A Versatile Companion

Acrylic resin, a thermoplastic, may be reshaped with heat due to its composition of acrylic polymers, granules, methyl methacrylate monomers, and a hardener. Its strength, durability, and UV resistance set it apart from epoxy resin as a versatile solution for outdoor applications. Acrylic resin is well-known in the realm of composites and carbon fiber goods for its versatility and wide range of uses. Here are some key aspects of acrylic resin:

Flexibility: This makes it a popular choice for items like sporting goods and consumer electronics. Acrylic resin is flexible, which can be useful in applications where the final product needs to withstand bending, vibration, or impact. This makes it a popular choice for items like sporting goods and consumer electronics.

Quick Cure: Acrylic resins often cure faster than epoxy resins. This rapid curing time can speed up production operations and shorten manufacturing lead times.

UV Resistance: Acrylic resins are resistant to ultraviolet (UV) light. As a result, they are often used in carbon fiber products intended for outdoor use, such as boat components or outdoor sporting equipment.

Cost-Effective: Acrylic resin is more cost-effective than epoxy resin, making it an appealing option for projects with limited budgets.

Transparency: Acrylic resin has great optical characteristics, making it transparent. It is frequently used in clear coatings and adhesives for applications requiring transparency, such as headlight lenses and windows in the automotive sector.

Epoxy Resin: The Strength and Durability Champion

Epoxy resin is a type of resin with robust mechanical qualities, good chemical resistance, and high adhesive strength, making it extremely useful for a wide range of applications. Here are some of the reasons why epoxy resin is a favored choice in the manufacture of carbon fiber products:

Adhesion Strength: Epoxy resin forms a strong bond with carbon fibers, resulting in a composite material with exceptional structural strength. This property makes it Indispensable in applications requiring exceptional strength and durability, such as aerospace components and high-performance racing equipment.

Chemical and Heat Resistance: Epoxy resins excel in resisting chemicals and high temperatures. They are often the preferred option for products used in hostile environments, such as chemical processing or under the hood of automobiles.

Longevity: Epoxy resin is well-known for its long-term performance and durability. It can ensure the longevity of carbon fiber products, making it the go-to option for items requiring a long service life.

Choosing the Right Resin for Carbon Fiber Products

When choosing the right resin for your carbon fiber products, consider the specific requirements of your project:

Strength and Structural Demands: If your project requires exceptional strength and structural stability, epoxy resin is the obvious choice.

Flexibility and Rapid Curing: Acrylic resin has advantages for tasks that require flexibility and rapid curing.

Environmental Exposure: Consider the environmental conditions that your product will be exposed to. Acrylic resin's UV resistance may be crucial for outdoor applications, while epoxy's chemical resistance might be needed in corrosive environments.

Budget Constraints: Acrylic resin is a cost-effective solution if you have a limited budget.

Customization: Epoxy resin's versatility allows for customization to meet specific project requirements or performance characteristics.

Famous Quote by Thomas Edison: "Opportunity is missed by most people because it is dressed in overalls and looks like work." Just like Edison's pursuit of innovation, choosing the right resin for your carbon fiber project requires diligence and careful consideration.

Conclusion

In the realm of carbon fiber manufacturing, the choice between acrylic and epoxy resins is a pivotal decision. Each resin brings its own set of strengths and characteristics to the table, addressing distinct project needs. By comprehending these differences and aligning them with your project's objectives, you can achieve exceptional results in creating top-tier carbon fiber products. Your choice of resin can actually unlock carbon fiber's full potential in your manufacturing endeavours. Whether you're aiming for the skies, racing on the ground, or harnessing the wind, the right resin selection can make all the difference.