Carbon Fiber Laminates vs Fiber Metal Laminate Composites

👁 Reads: 803

Among the numerous advanced materials, composite materials are currently leading innovation with their several exceptional properties. Carbon fiber laminates and fiber metal laminate composites occupy a special place due to their characteristics and uses. Both of materials have excellent strength to weight ratio and have transformed numerous sectors including aerospace and automobile. But distinguishing between these two composite materials can be useful when choosing the right material for a particular application. This article focuses on the description of carbon fiber laminates and fiber metal laminate composites to give a comparison of the characterization, benefits, and uses of the products. Let's begin with carbon fiber laminate composites.

Carbon Fiber Laminates

Carbon fiber laminates is a top-notch carbon fiber product made by stacking fabric layers of carbon fiber, then bonding them with a matrix of resin. Through this process, manufactures obtain a material that has high strength while at the same time light weight which can be used on different performance-oriented applications. A carbon fiber laminate sheet is a fairly stiff and strong component that can be employed in applications where such characteristics are vital. This material takes full advantage of carbon fibers' strength and stretchiness and skips the hardening part of resin in construction fabrics. It is super-efficient in using its strength and easy to work with. Thanks to the natural qualities of carbon fibers and how versatile laminate designs are, they are perfect for lots of different uses. You will often see laminated carbon fiber being used to make buildings stronger, like in beefing up concrete structures. They can handle over five times the stretch force compared to a 300g carbon sheet of the same size.

Properties of Carbon Fiber Laminates

- Strength and Weight – Carbon fiber laminates have the tensile strength of steel with only one third of the weight and this makes it ideal for use in areas that require high strength with minimal weight.

- Durability – These laminates are very reliable and durable hence provide long term performance even under rigorous usage.

- Thermal Stability – laminated Carbon fiber products are stable at high temperatures without undergoing any changes in their mechanical properties which is important in cars and planes.

- Corrosion Resistance - There is no corrosion problem associated with carbon fiber laminates for they are not metallic and can even be used in most unfavorable conditions.

- Aesthetic aspect – The material is lightweight and has a very elegant and smooth look that is appreciated especially for visible parts of automobiles and other consumer goods.

Applications of Carbon Fiber Laminates

- Aerospace– Carbon fiber laminates are applied in primary aircraft structures such as fuselage, vertical tail, empennage box and wing, and replacing conventional lightweight metal alloys. For instance, the rudder, control surface, fuselage side panel, stabilizer, etc. of the Boeing 777 dream liner plane was constructed with carbon fiber laminates that make it lighter thus, more economical in terms of fuel consumption.

- Automotive– research shows that carbon fiber composites have been used for automobile production, including 5000 supercars, 500,000 premium luxury cars, 5 million luxury cars and 100 million non-luxury cars. Carbon fiber laminate is used in high performance cars to decrease the car weight and increase fuel economy. Carbon fiber laminates are applied in body panels, chassis aspects and interior trim.

- Sports equipment– Used in the production of bicycles, golf clubs, and other sport requisites for better quality. Carbon fiber bicycles are identified for its lightness and rigidity, it is more efficient than the other materials.

- Marine– Applied in boat hulls and racing yachts since they are light and do not corrode easily. Carbon fiber laminates assist in enhancing the speed and the fuel consumption in the marine vessels.

- Construction – Strengthening of buildings and infrastructures using carbon fiber laminates is a construction application that is receiving more attention. They enhance the concrete and steel elements and increase their load-carrying capability and durability. In seismic zones, by wrapping columns, beams, and other critical structural elements in carbon fiber laminate sheet, buildings are better equipped to handle the stresses caused by earthquakes.

- For Medical Devices – They are also applied when designing prosthetics and some other medical imaging equipment because of their strength and biocompatibility.

Fiber Metal Laminate

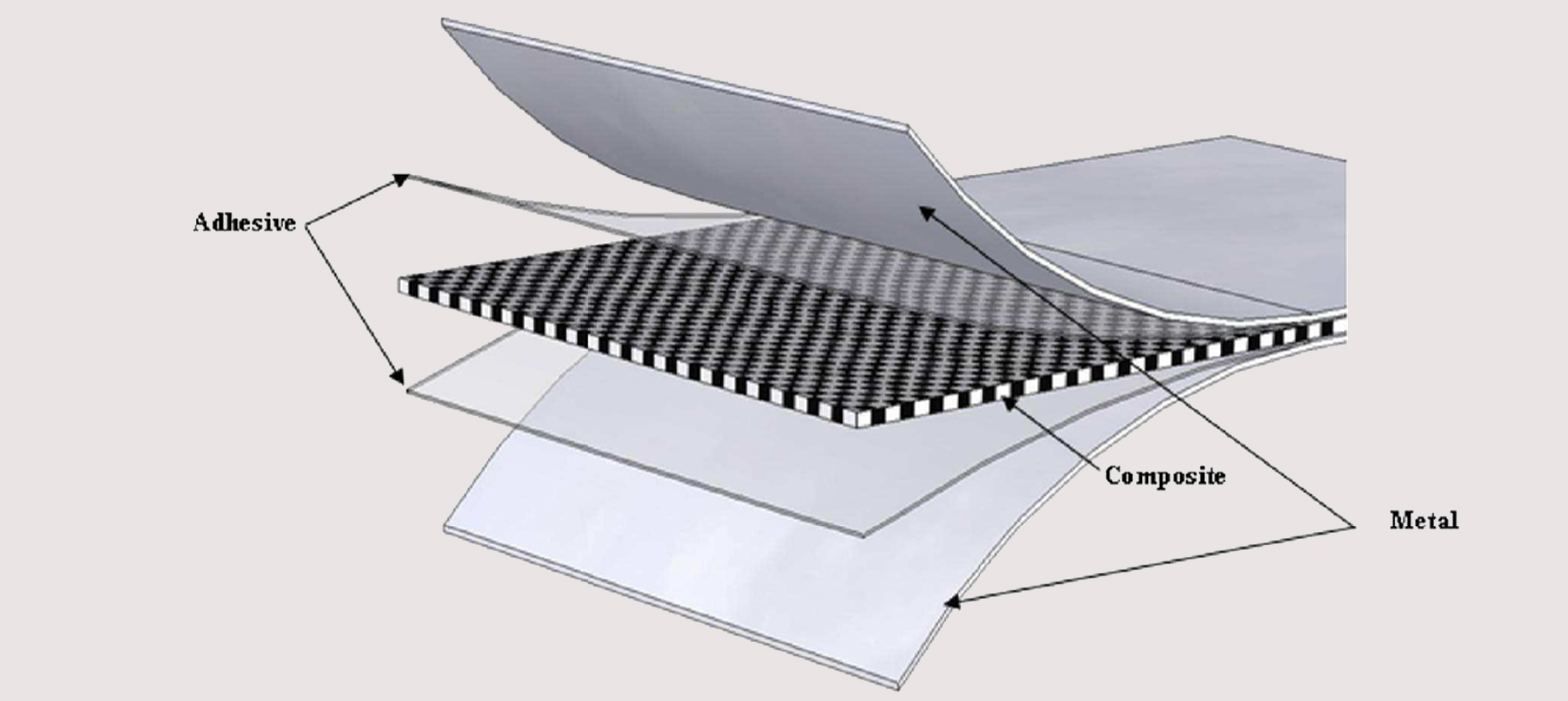

The Fiber Metal Laminate composites consist of a stack of metal sheets bonded with fiber reinforced polymer. Usually, these composites have layers of metal (Aluminum for instance) and composites like carbon or glass fibers. This compound structure combines the advantages of metals and fiber reinforced materials, and thus has some properties that are very unique.

Properties of Fiber Metal Laminate Composites

- Strength– Metal and fiber layers make it strong and the material is not easily damaged when hit.

- Damage Tolerance– these composites are built to withstand and endure damages which makes them suitable for use in areas that require high levels of safety or strength.

- Fatigue Life– The fiber metal laminate composites show a higher fatigue life than all those conventional metals and this results in the increased durability of the components made with this material.

- Thermal Insulation– The composite structure is capable of offering good thermal insulation thus suitable for aerospace and automotive applications.

- Noise Reduction-These can also be used as noise reducers since they are capable of decreasing the levels of noise in the composite structures.

Applications of Fiber Metal Laminate Composites

- Aerospace – FMLs offer the potential for increased resilience and safety in aircraft structures. By incorporating advanced materials and innovative designs, FMLs can exhibit superior damage tolerance and fracture toughness. For instance, the bottom flap shell of C130 by Lockheed Martin was made from fiber metal laminate composites.

- Automotive – used to make body panels and safety structures to increase the resistance to impacts and enhance safety.

- Defense – Applied in the manufacturing of protective gears, and armored car for increased durability and impact resistance. Fiber metal laminates are used in the military for bullet proof jackets. Another of such shielding applications include whipple shields which protect the satellites and spacecrafts against hyper-velocity impact

- Railway – Used in train bodies and other parts for better strength and to reduce the noise.

- Construction – Used in building facades and structural components for their strength and longevity.

Summary: Carbon Fiber Laminates vs Fiber Metal Laminate

Property |

Carbon Fiber Laminates |

Fiber Metal Laminate |

Weight |

Lighter |

Heavier than carbon fiber laminates |

Strength |

High tensile strength and stiffness |

Excellent strength and impact resistance |

Durability |

High |

High |

Thermal Resistance |

Excellent |

Good |

Corrosion Resistance |

Excellent |

Good |

Noise Reduction |

Moderate |

Superior noise and vibration damping |

Cost |

Higher due to complex production process |

Moderate to high |

Manufacturing Complexity |

Complex |

Moderate to complex |

Conclusion

Carbon fiber laminates and fiber metal laminate composites have their advantages and disadvantages, and thus suitable for different high-performance uses. In selecting these materials, it is important to consider the particular needs of the specific application. Whether you require the stiffness and low weight of carbon fiber laminates or the toughness and flexibility of fiber metal laminates, knowing the features of each will assist you in your choice. Thus, both materials will continue to develop, and their application and performance characteristics will be even more unique and effective in various fields.