Know the Difference Between Carbon Fiber Sheets and Carbon Fiber Plates?

👁 Reads: 5174

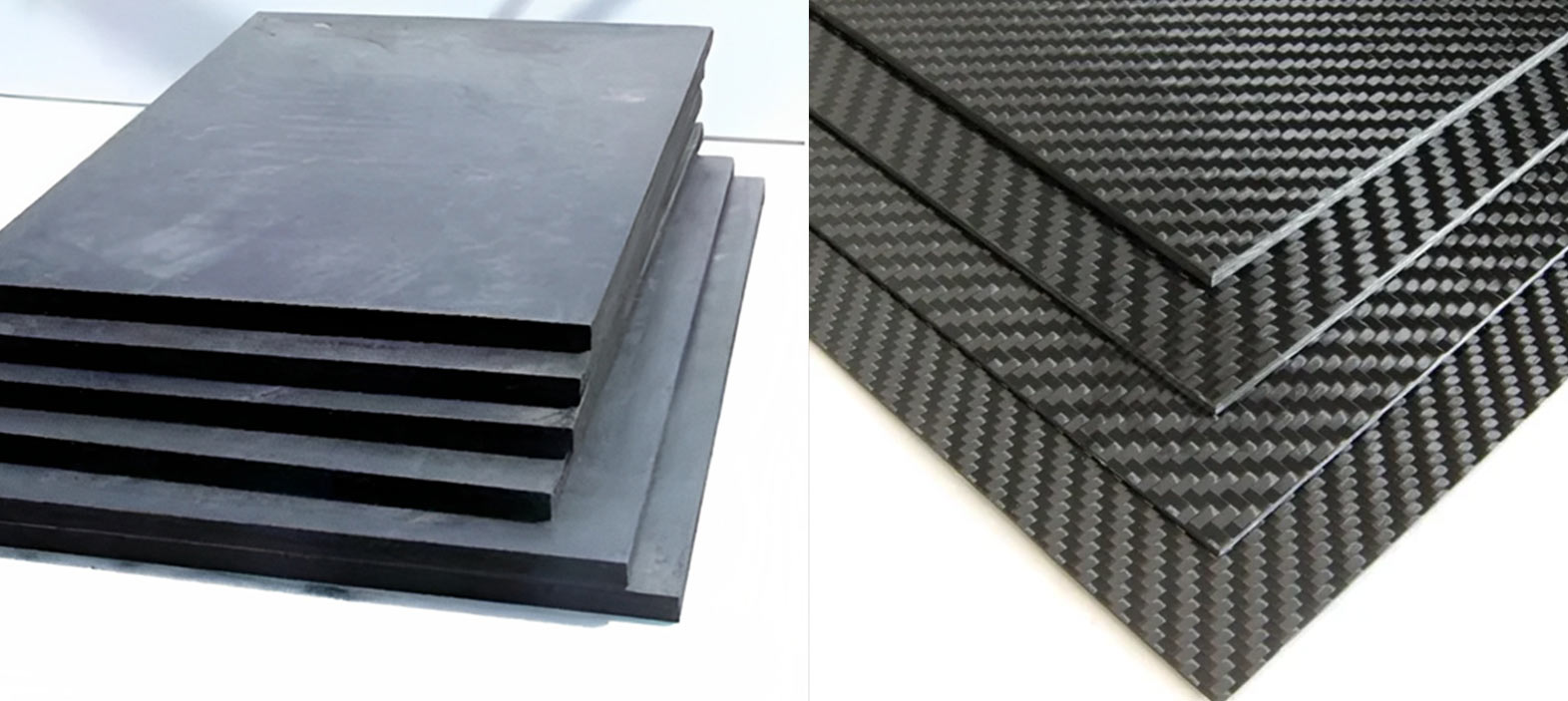

Carbon fiber is an advanced material that has gained widespread popularity due to its strength and lightweight properties. This high-tech material is used in various industries, including aerospace, motorsports, and construction. There are two forms of carbon fiber used in the manufacturing process: carbon fiber sheets and carbon fiber plates. Both have their own advantages and disadvantages, and it is important to understand the differences between them before making a purchasing decision.

Carbon Fiber Sheets

A carbon fiber sheet is a flat piece of carbon fiber composite material. They are usually made from woven carbon fiber fabric that has been impregnated with a resin, such as epoxy, to form a rigid and strong composite. It can be cut and drilled to suit a variety of applications, making them highly versatile.

Different Types of Carbon Fiber Sheets

1. Carbon Fiber Vacuum Infusion Sheets

Vacuum infusion sheets are made by laying a layer of dry carbon fiber fabric onto a mold and then using a vacuum to force the resin into the fabric. The mold of carbon fiber vaccum infusion sheet is then placed under pressure to ensure a uniform distribution of resin and to minimize the voids or air pockets that may form during the curing process.

Advantages of Vacuum Infusion Sheets

- Excellent bonding strength between the fibers and the resin

- Consistent and uniform thickness

- High-quality finish

Disadvantages of Vacuum Infusion Sheets

- High manufacturing cost

- Complex manufacturing process

- Long lead time for production

2. Carbon Fiber Compression Molded Sheet

Compression molded sheets are made by placing a layer of dry carbon fiber fabric and resin into a mold, which is then placed under high pressure to form a solid composite. The molding process of Carbon Fiber Compression Molded Sheet ensures that the fibers and resin are tightly packed together, resulting in a high-quality finish.

Advantages of Compression Molded Sheets

- Low manufacturing cost

- Simple manufacturing process

- Short lead time for production

- High-quality finish

Disadvantages of Compression Molded Sheets

- Lower bonding strength between the fibers and the resin

- Inconsistent thickness

Carbon Fiber Plates

A carbon fiber plate is a thick and rigid piece of composite material, made from multiple layers of carbon fiber fabric and resin. CF plates are often used in aerospace, motorsports, and construction applications due to their high strength-to-weight ratio.

Different Types of Carbon Fiber Plates

1. Autoclave-Cured Carbon Fiber Plates

Autoclave-cured CF plates are made by laying multiple layers of carbon fiber fabric and resin into a mold, which is then placed into an autoclave. The autoclave applies pressure and heat to the mold, causing the resin to cure and the fibers to bond together. This process results in a high-quality, lightweight, and strong carbon fiber plate.

Advantages of Autoclave-Cured CF Plates

- High strength-to-weight ratio

- Excellent bonding strength between the fibers and the resin

- Consistent and uniform thickness

Disadvantages of Autoclave-Cured CF Plates

- High manufacturing cost

- Complex manufacturing process

- Long lead time for production

2. Hand-Laid Carbon Fiber Plates

Hand-laid CF plates are made by laying multiple layers of carbon fiber fabric and resin by hand, in a similar fashion to vacuum infusion sheets. Hand-laid plates are then placed under pressure to ensure a uniform distribution of resin and to minimize the voids or air pockets that may form during the curing process.

Advantages of Hand-Laid CF Plates

- Low manufacturing cost

- Simple manufacturing process

- Short lead time for production

Disadvantages of Hand-Laid CF Plates

- Lower bonding strength between the fibers and the resin

- Inconsistent thickness

- Risk of air pockets and voids in the composite

Applications

CF sheets and plates have a wide range of applications due to their strength and lightweight properties. Some of the most common applications are:

- Aerospace: Carbon fiber is used in the manufacture of aircraft components, including fuselage panels, wing skins, and engine nacelles.

- Motorsports: Carbon fiber is used in the manufacture of high-performance racing vehicles, including chassis, body panels, and suspension components.

- Construction: Carbon fiber is used in the reinforcement of concrete structures, such as bridges and building foundations, to increase their strength and durability.

- Sporting goods: Carbon fiber is used in the manufacture of high-performance sports equipment, including golf clubs, fishing rods, and bicycle frames.

Conclusion

In conclusion, carbon fiber sheets and plates are versatile composite materials that have a wide range of applications due to their strength and lightweight properties. CF sheets are flat pieces of composite material, typically made from woven carbon fiber fabric and resin. CF plates are thick and rigid pieces of composite material, made from multiple layers of carbon fiber fabric and resin. It is important to understand the differences between the two forms of carbon fiber and their applications, to make an informed purchasing decision. Whether you choose CF sheets or plates, you can be confident that you are getting a high-quality, high-performance composite material that will provide many benefits over traditional materials.