How to make carbon fiber fairings?

👁 Reads: 1781

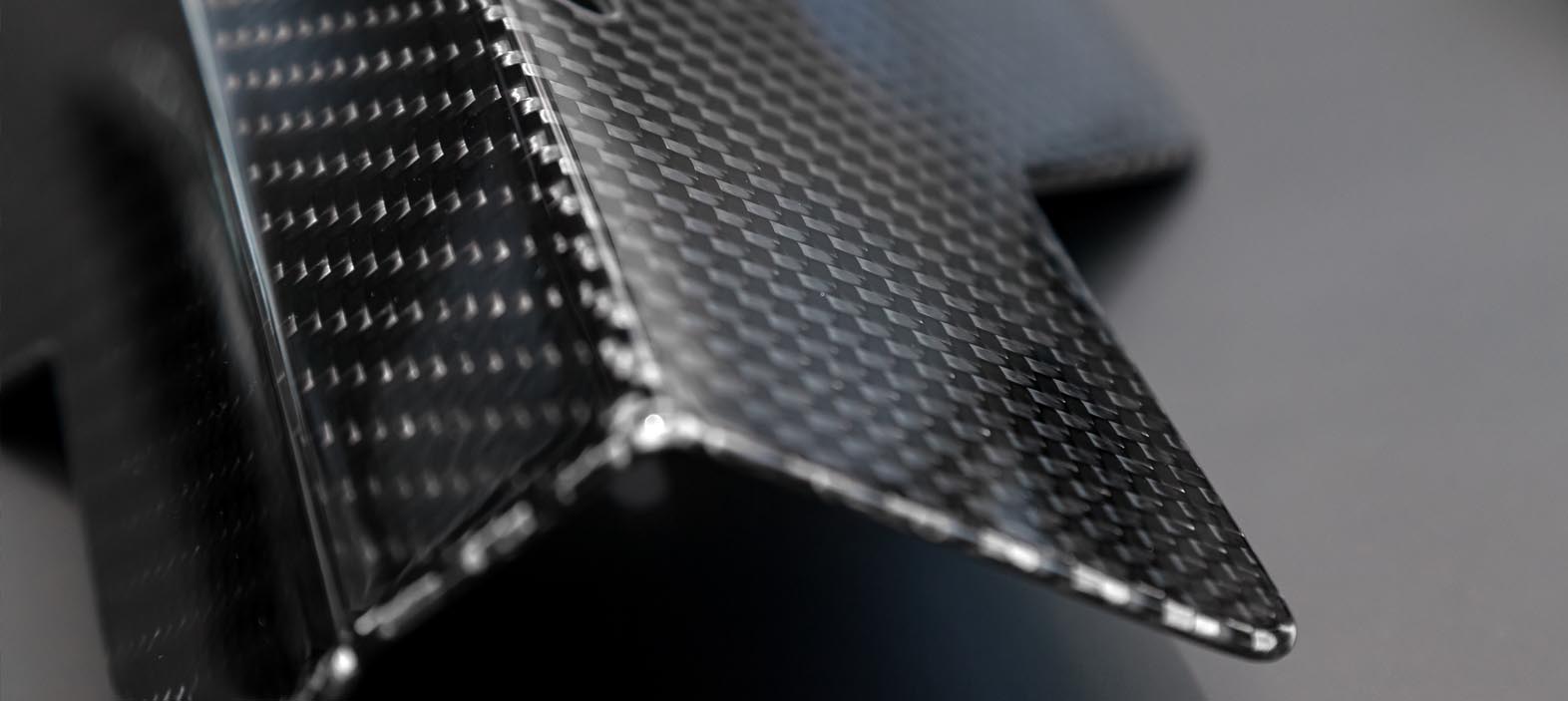

Carbon fiber is a material that has revolutionized many industries, including aerospace, automotive, and sporting goods. It is made by weaving fibers together and bonding them with a resin to create a strong, lightweight composite material. It is incredibly strong, yet lightweight, making it ideal for use in applications where weight reduction is critical.

Carbon fiber fairings are a perfect example of how CNC Carbon Fiber Parts can be used to create products that are both strong and lightweight. They are commonly used in the automotive industry to improve the aerodynamics of race cars and high-performance vehicles. Carbon Fiber Products are also used in the aerospace industry to reduce the weight of aircraft and improve fuel efficiency.

The process of making the fairings involves several steps, including designing, molding, cutting, laying up, curing, trimming, and finishing. Each of these steps requires skill and expertise to ensure that the final product is of the highest quality. One of the key challenges in making carbon fiber fairings is ensuring that the CNC Carbon Fiber Parts are laid up correctly to achieve the desired strength and stiffness.

The Process Of Making Carbon Fiber Fairings

Carbon fiber fairings are an essential component in modern transportation and manufacturing industries. They are lightweight, durable, and offer superior strength-to-weight ratios compared to traditional materials. Here is the process of making the fairings.

Step 1: Design

The first step in making fairings is to design the fairing. This involves creating a CAD (computer-aided design) model of the fairing using software such as SolidWorks or AutoCAD. The CAD model will serve as a blueprint for the fairing's shape and dimensions.

Step 2: Mold Preparation

Once the CAD model is complete, the next step is to create a mold for the fairing. The mold is typically made from fiberglass or carbon fiber and is created using the CAD model. The mold needs to be smooth and free of any imperfections to ensure that the final product is smooth and uniform.

Step 3: Cutting Carbon Fiber Sheets

The next step is to cut carbon fiber sheets to the shape and size of the fairing. This is done using a template created from the CAD model. The sheets are usually cut using a CNC (computer numerical control) machine to ensure accuracy and consistency.

Step 4: Applying Resin

Once the CNC Carbon Fiber Parts have been cut to size, the next step is to apply a resin to the sheets. The resin is used to bond the sheets together and provide rigidity and strength to the final product. Epoxy resin is commonly used in this process, and it is important to use the correct ratio of resin to hardener to ensure that the resin cures properly.

Step 5: Laying Up Carbon Fiber Sheets

After applying the resin, the sheets are laid up onto the mold. The sheets are placed on the mold in a specific order, and care is taken to ensure that there are no air bubbles or wrinkles in the sheets. The sheets are then pressed onto the mold to ensure that they conform to the shape of the mold.

Step 6: Curing

The next step is to cure the sheets. This is done by placing the mold and sheets into a vacuum bag and applying heat and pressure. The vacuum bag removes any excess air from the mold, and the heat and pressure help to cure the resin. The curing process can take several hours to complete.

Step 7: Trimming

Once the fairing has cured, it is removed from the mold and trimmed to its final shape and size. This is done using a router or other cutting tool to ensure that the fairing is smooth and uniform.

Step 8: Finishing

The final step in making a fairing is finishing. This involves sanding and polishing the fairing to give it a smooth, glossy finish. The fairing may also be painted or clear coated to protect it from UV rays and other environmental factors.

Conclusion

Making carbon fiber fairings requires a great deal of skill and expertise. It is a complex process that involves designing, molding, cutting, laying up, curing, trimming, and finishing the fairing. However, the result is a lightweight, durable, and strong product that is essential in modern transportation and manufacturing industries. By following the steps outlined in this article, you can make your own carbon fiber fairings and enjoy the many benefits that this material has to offer.