Understanding the Strength and Versatility of Carbon Fiber Laminate

👁 Reads: 501

👁 Reads: 502

Carbon fiber laminates are super strong and flexible materials made by applying a resin to the fabric and then curing it with heat. This material is not only popular in luxury items but it's also known for being really light but still very sturdy. This makes it perfect for things like aeroplanes and cars, where keeping weight down is very important. This article will talk all about how strong and useful carbon fiber laminates can be.

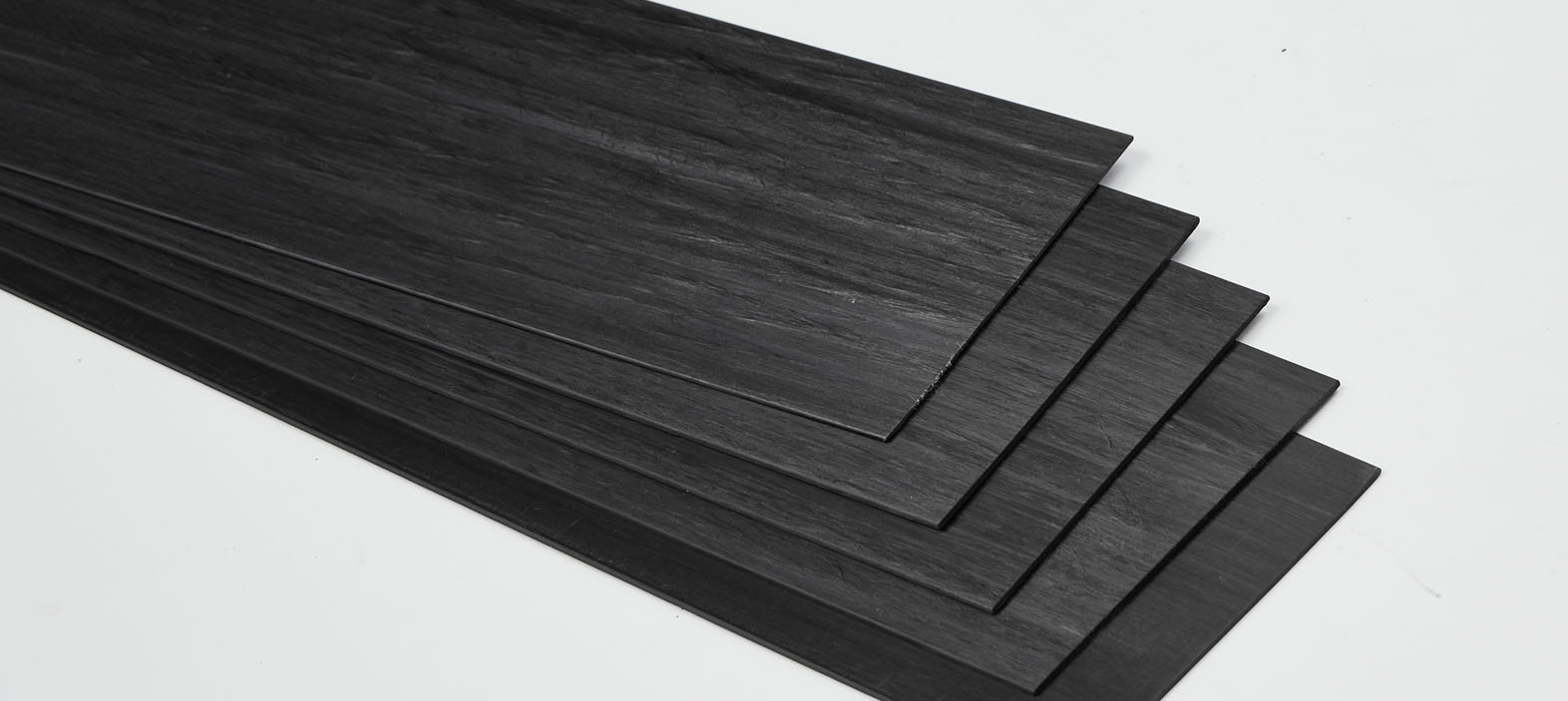

Carbon Fiber Laminates

Carbon fiber laminate is a top-notch material made by hardening carbon fiber strips soaked in resin through a die and continuous pulling. This makes a really strong sheet, that can stand up against corrosion, shakes, and hits. This material takes full advantage of carbon fibers' strength and stretchiness and skips the hardening part of resin in construction fabrics. It is super-efficient in its strength and easy to work with. Thanks to the natural qualities of carbon fibers and how versatile laminate designs are, they are perfect for lots of different uses. You will often see carbon fiber laminates used to make buildings stronger, like beefing up concrete structures. They can handle over five times the stretch force compared to a 300g carbon sheet of the same size.

Strength in Design

Carbon fiber laminates are super strong yet light. You can pick the size and thickness you need for your project. They stick onto surfaces with a special glue called epoxy resin. When you compare it to conventional materials like steel or aluminium, carbon fiber laminate is way stronger. It doesn't bend under heavy loads and doesn't rust. Plus, you can use as much of it as you want. It is also easy to install, even above your head, and it has a high modulus of elasticity, outstanding fatigue resistance, and alkali resistance. You can even make simple layers overlap with it.

Carbon fiber laminate is made using a basic strength, one-way prepreg set in a 0°/90° layout to keep it even and balanced. This setup gives it great strength and stiffness both lengthwise and crosswise. The 0° Uni Sheets are laid out straight or lengthwise to add stiffness in one direction. The 0°/90° Unidirectional Sheet balances strength, evenness, and cost well. Thanks to these key features, they are crucial in fields that need strong structures, like in building, transport, and making sports equipment.

Versatility

Carbon fiber laminates are super useful in lots of areas. In civil engineering, they enhance the mechanical resistance of structures by reinforcing materials like wood, concrete, and polystyrene with carbon fibers and epoxy resins. In the aviation, marine, and automotive sectors, carbon fiber laminates are extensively used, with adhesive bonding playing a crucial role in joining composite parts. Also, in really high-tech planes, carbon fiber laminates can protect against lightning, help sense if something is stretching, and keep electronics from getting messed up by outside signals. Plus, when you mix carbon fibers with metals, you get materials that can take a hit well and are great for making stuff in the aerospace and car industries lighter and stronger. They are also used in making safe gear, planes, and high-end products for everyday use because they are light, strong, and can handle heat well. Additionally, the sustainability of carbon fiber laminates allows for their reuse in various industries due to their high mechanical strength, aiding in cost-effective and eco-friendly composite productions.

Innovations Driving Progress

Recent improvements in manufacturing technologies have advanced carbon fiber laminates, opening up new chances to create and be more efficient. Innovations in carbon fiber laminates are propelling advancements in material strength and durability. Research has focused on enhancing interfacial chemistry and developing self-healing properties through novel approaches like incorporating ZnO nano-rods and graphene oxide into the matrix. Additionally, efforts have been made to improve mechanical properties by modifying fiber-matrix interfaces. Paradigm-shifting findings have led to the development of new design concepts, such as variable ply angles and Double-Double architectures, resulting in stronger and more cost-efficient laminates. Research has shown that the addition of copper mesh in layers can significantly improve the performance of carbon fiber products, reducing resistivity by 91.77% and increasing impact strength by 14.19%. Additionally, the mechanical properties of composite materials can be enhanced by laminating carbon fibers with epoxy resins, leading to increased load-bearing capacity and improved resistance to bending, compression, fire, and shock. These innovations collectively drive the progress of carbon fiber laminates towards higher performance and versatility.

Conclusion

In conclusion, carbon fiber laminate is super strong and flexible, revolutionizing industries ranging from civil engineering to aerospace. Carbon fiber laminate is tough, does not rust, and can be made to fit lots of different needs, making it super important for making structures stronger. With new ways of making it getting better all the time, it is going to be even more useful as we move forward. Carbon fiber products are setting new standards for what we can do with materials, influencing future innovation projects.