What is Carbon Fiber Laminate? A Complete Beginner’s Guide

👁 Reads: 79

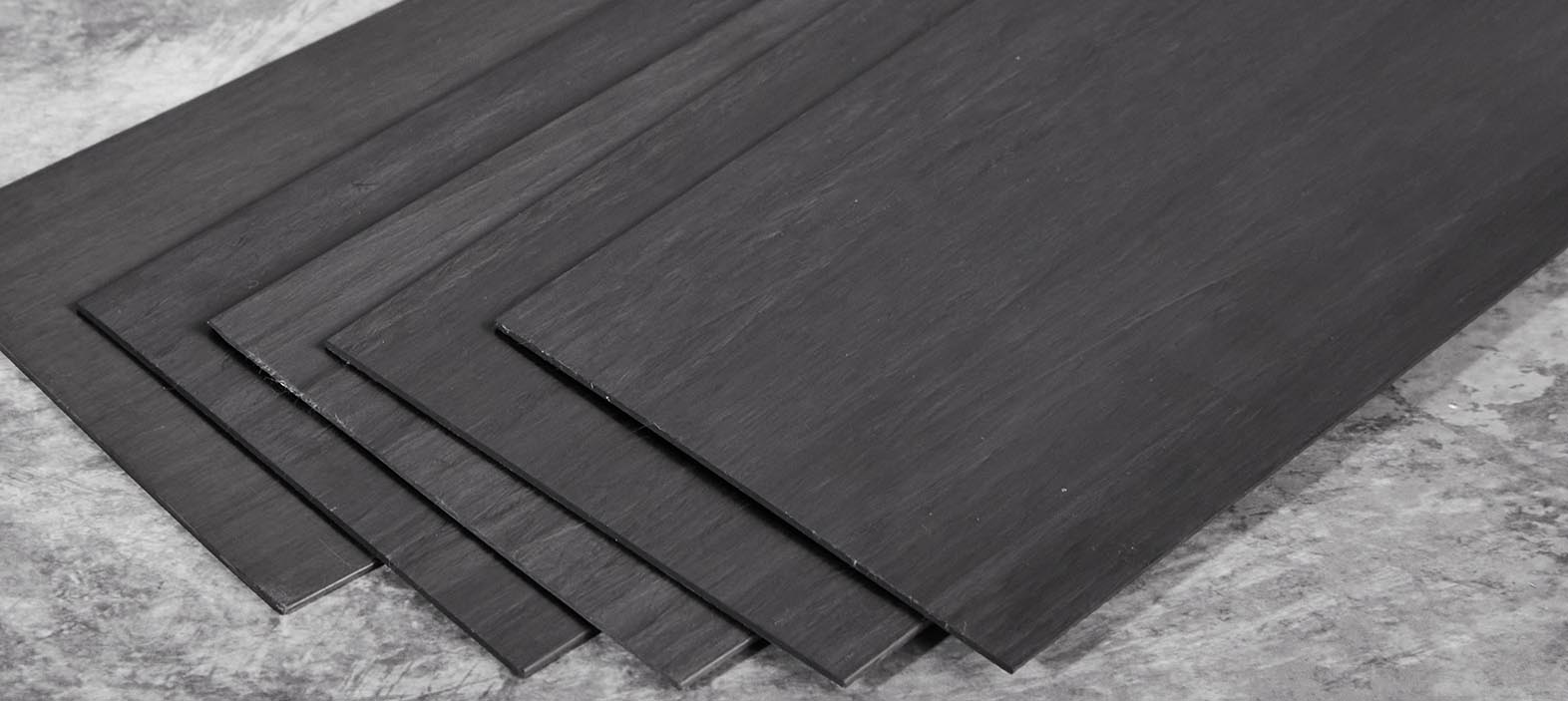

Carbon fiber laminate is a revolutionary composite material that combines exceptional strength with minimal weight, transforming industries from aerospace to sporting goods. This comprehensive guide explores everything you need to know about carbon fiber laminates - from manufacturing processes to practical applications and choosing the right type for your project.

What Is Carbon Fiber Laminate?

Carbon fiber laminate is a composite material made by layering carbon fiber fabrics impregnated with resin. These layers are bonded together through curing processes to form a rigid sheet or structure. The result is a material that combines the lightweight properties of carbon fibers with the strength and durability of the resin matrix. This engineered combination delivers performance characteristics that surpass traditional materials like aluminum or steel.

For example, in aerospace and automotive applications, carbon fiber laminates are used to create lightweight yet strong components like panels, wings, or chassis parts. These laminates are also popular in consumer goods such as sporting equipment and luxury accessories due to their sleek woven appearance. For strengthening buildings, bridges and other structures.

How Is Carbon Fiber Laminate Made?

The manufacturing process of carbon fiber laminate involves several steps:

- Layup: Layers of carbon fiber fabric are arranged in specific orientations to achieve desired mechanical properties.

- Resin Application: Resin (typically epoxy) is applied to the fabric layers to bind them together. This can be done manually (wet lay-up) or using pre-impregnated (prepreg) sheets.

- Curing: The laminate is cured under heat and pressure in an autoclave or vacuum bag to solidify the resin and form a rigid structure.

- Post-Processing: The cured laminate may be trimmed or machined into its final shape.

The precision of this process ensures consistent quality and performance, making it suitable for demanding applications like aerospace components or UAV structures.

Key Properties of Carbon Fiber Laminate

Carbon fiber laminates possess several unique properties that make them highly desirable:

- Lightweight: They are significantly lighter than metals like steel or aluminum while offering comparable strength.

- High Strength and Stiffness: Carbon fiber laminates have excellent tensile strength and rigidity, making them ideal for load-bearing applications.

- Durability: Resistant to corrosion and environmental degradation, they perform well in harsh conditions.

- Thermal Stability: They maintain mechanical properties at high temperatures, making them suitable for aerospace and automotive uses.

- Vibration Dampening - Absorbs vibrations for improved comfort and performance

- Corrosion Resistance - Impervious to rust and most chemical degradation

- Aesthetic Appeal: The woven texture adds a sleek, modern look, often used in visible parts of products like luxury cars or electronics.

Common Applications

Carbon fiber laminates are used across various industries due to their versatility:

- Aerospace: Aircraft wings, fuselage panels, and satellite components benefit from their lightweight strength.

- Automotive: High-performance cars use laminates for body panels, dashboards, and structural reinforcements.

- Drones & UAVs: Lightweight frames allow drones to achieve better flight efficiency.

- Medical Devices: Prosthetics and imaging equipment use laminates for their strength and biocompatibility.

- Sporting Goods: Items like tennis rackets, bicycles, and skis leverage the material’s durability and lightweight nature.

Types of Carbon Fiber Laminates

There are several types of carbon fiber laminates tailored to specific needs:

Type |

Description |

Applications |

Unidirectional |

Fibers aligned in one direction for maximum tensile strength along that axis |

Beams, slabs, columns |

Bidirectional (Woven) |

Fibers woven in two directions for balanced strength |

Bridge decks, walls |

Prepreg |

Pre-impregnated with resin for precise control over resin-to-fiber ratio |

Aerospace parts, race cars |

Pultruded |

Continuous process ensures uniform cross-section with excellent stiffness |

Infrastructure projects like bridges |

Hybrid |

Combines carbon fibers with other materials (e.g., glass fibers) for improved impact resistance |

Seismic reinforcements |

Each type offers unique advantages depending on the application requirements.

Carbon Fiber Laminate vs Solid Carbon Fiber vs Veneer

Understanding the differences between these forms helps in selecting the right material:

Feature |

Carbon Fiber Laminate |

Solid Carbon Fiber |

Carbon Fiber Veneer |

Structure |

Layered composite |

Single solid piece |

Thin decorative layer |

Strength |

High |

Very high |

Low |

Weight |

Lightweight |

Heavier than laminate |

Very light |

Applications |

Structural components |

High-stress parts |

Aesthetic purposes |

For structural uses requiring both strength and lightness, laminates are often the best choice.

Carbon fiber laminate is an advanced material that combines lightweight properties with exceptional strength and durability. Its versatility makes it indispensable across industries ranging from aerospace to consumer goods. Whether you’re designing drones or sourcing materials for automotive modifications, understanding the types and properties of carbon fiber laminates can help you make informed decisions.

Frequently Asked Questions About Carbon Fiber and Fire

With proper design and protection from UV exposure, carbon fiber laminates can maintain their structural properties for 20+ years in most applications.

While more costly than traditional materials like steel or aluminum, carbon fiber laminate often provides long-term value through performance benefits, reduced maintenance, and extended service life.

Yes, specialized repair techniques exist for carbon fiber laminates, though they typically require professional expertise to maintain structural integrity.

The durability and lightweight nature of carbon fiber can reduce lifetime environmental impact through fuel savings and longevity, though end-of-life recycling remains challenging compared to metals.

Specialized tools, including diamond-tipped cutters and water jet systems are typically used to shape carbon fiber laminate without compromising its structural integrity.

With proper design and protection from UV exposure, carbon fiber laminates can maintain their structural properties for 20+ years in most applications.

While more costly than traditional materials like steel or aluminum, carbon fiber laminate often provides long-term value through performance benefits, reduced maintenance, and extended service life.

Yes, specialized repair techniques exist for carbon fiber laminates, though they typically require professional expertise to maintain structural integrity.

The durability and lightweight nature of carbon fiber can reduce lifetime environmental impact through fuel savings and longevity, though end-of-life recycling remains challenging compared to metals.

Specialized tools, including diamond-tipped cutters and water jet systems are typically used to shape carbon fiber laminate without compromising its structural integrity.