What Is Prepreg Carbon Fiber?

👁 Reads: 468

Carbon fiber composites are advanced materials that are widely used in various industries such as aerospace, sports, and automotive. They are made of carbon fiber reinforced polymer matrix, which is a combination of carbon fiber and resin. Carbon fiber is a strong, lightweight, and stiff material, while the resin binds the fibers together to form a composite structure. The combination of these two materials provides the carbon fiber composite with exceptional mechanical properties.

Carbon Fiber

Carbon fiber is a material that is made by heating fibers of carbon to a high temperature in the absence of air. The heating process removes all impurities and other non-carbon elements, leaving behind a high-strength, low-weight material. Carbon fibers are five times stronger than steel and one-fifth of its weight. This makes them an ideal material for many applications that require strength and low weight, such as aircraft and spacecraft components, race car bodies, and sports equipment.

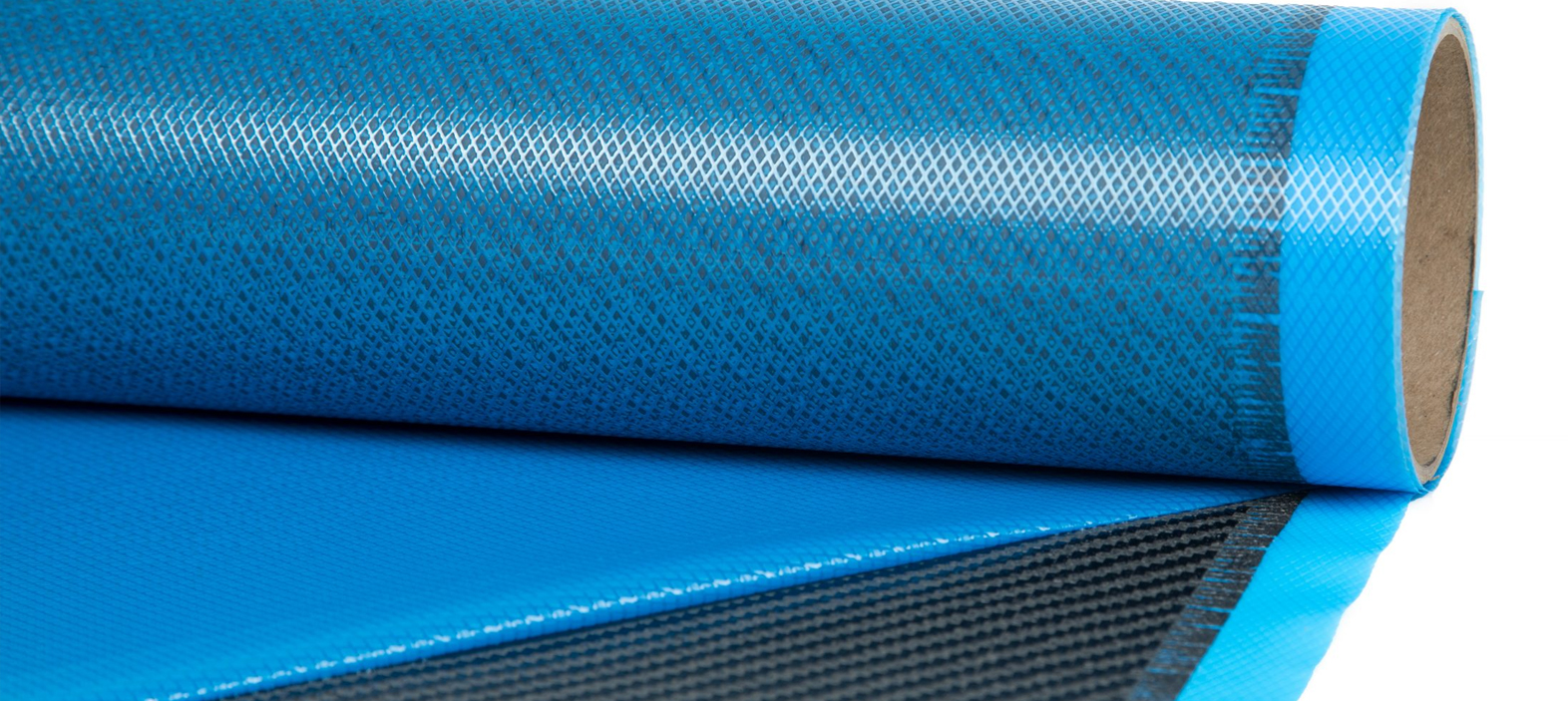

Pre-preg Carbon Fiber

Pre-preg carbon fiber refers to unidirectional carbon fiber sheets that have been impregnated with resin prior to use. The carbon fiber is infused with a controlled amount of resin and is then cured in a controlled environment to ensure the correct amount of resin is present. This results in a material that is ready to use and requires no additional processing to make it usable.

Benefits of Pre-preg Carbon Fiber

There are several benefits to using pre-preg carbon fiber, including:

1. Consistency:

Pre-preg carbon fiber has a consistent and controlled amount of resin, which results in a consistent and uniform composite structure. This is important for applications that require high-precision, such as aerospace and automotive components.

2. Improved Strength:

The uniform and consistent resin content in pre-preg carbon fiber results in a stronger and stiffer composite structure. This makes it ideal for applications that require high strength and stiffness, such as sports equipment and aircraft components.

3. Reduced Processing Time:

The use of pre-preg carbon fiber reduces the processing time required to produce a composite structure. This is because the resin infusion and curing process has already been done, and the material is ready to use.

4. Improved Quality:

Pre-preg carbon fiber has a higher quality and consistency compared to other carbon fiber composites. This is because the resin infusion and curing process is done under controlled conditions, which results in a high-quality and uniform composite structure.

Applications of Pre-preg Carbon Fiber

Pre-preg carbon fiber is widely used in various industries, including:

1. Aerospace:

Pre-preg carbon fiber is widely used in the aerospace industry for the manufacture of aircraft components, such as wings, fuselage, and other structural parts. The high strength and low weight of pre-preg carbon fiber make it ideal for use in the aerospace industry.

2. Sports:

Pre-preg carbon fiber is used in the manufacture of high-performance sports equipment, such as golf clubs, tennis racquets, and bicycles. The strength and stiffness of pre-preg carbon fiber provide improved performance for athletes.

3. Automotive:

Pre-preg carbon fiber is used in the automotive industry for the manufacture of high-performance racing car components, such as body panels, chassis, and suspension parts. The low weight and high strength of pre-preg carbon fiber make it ideal for use in the automotive industry.

Conclusion

Pre-preg carbon fiber is a high-quality and consistent material that is widely used in various industries, including aerospace, sports, and automotive. The controlled resin infusion and curing process results in a consistent and uniform composite