What is Unidirectional Carbon Fiber?

👁 Reads: 927

Unidirectional carbon fiber is a type of strong, lightweight material that is often used in the aerospace and automotive industries, as well as in medical devices, sporting goods, and consumer products. It is made of a combination of carbon fibers and a resin-based binder, and is available in various forms, such as tape, sheet, and fabric.

The term “unidirectional” refers to the orientation of the fibers, which are lined up in a single direction. This ensures that the fibers are all pulling in the same direction, making the material stronger and more rigid than non-unidirectional materials. The fibers also interlock with each other, further increasing the strength of the material.

When compared to traditional materials like steel and aluminum, unidirectional carbon fiber is much lighter and stronger. It has a high tensile strength, meaning that it can handle much higher amounts of stress before breaking. The material is also highly resistant to corrosion, making it an ideal choice to buy carbon fiber tubes and other applications that require extended exposure to the elements.

In terms of cost, unidirectional carbon fiber is more expensive than other materials. It is also difficult to work with, requiring special tools and techniques. Despite these drawbacks, its superior strength and durability make it a popular choice for specialized applications.

Unidirectional carbon fiber is used in a variety of products, from sports equipment to medical implants. Its light weight, high strength, and corrosion resistance make it an ideal choice for applications that require strong, lightweight materials. Although it is more expensive than other materials, its superior properties make it a worthy investment.

How is Unidirectional Carbon Fiber Different From Woven Carbon Fiber?

Unidirectional carbon fiber and woven carbon fiber are two important materials in the composite industry. Both materials have unique properties that make them useful in different applications. Understanding the differences between the two can help you choose the material that is best for your project.

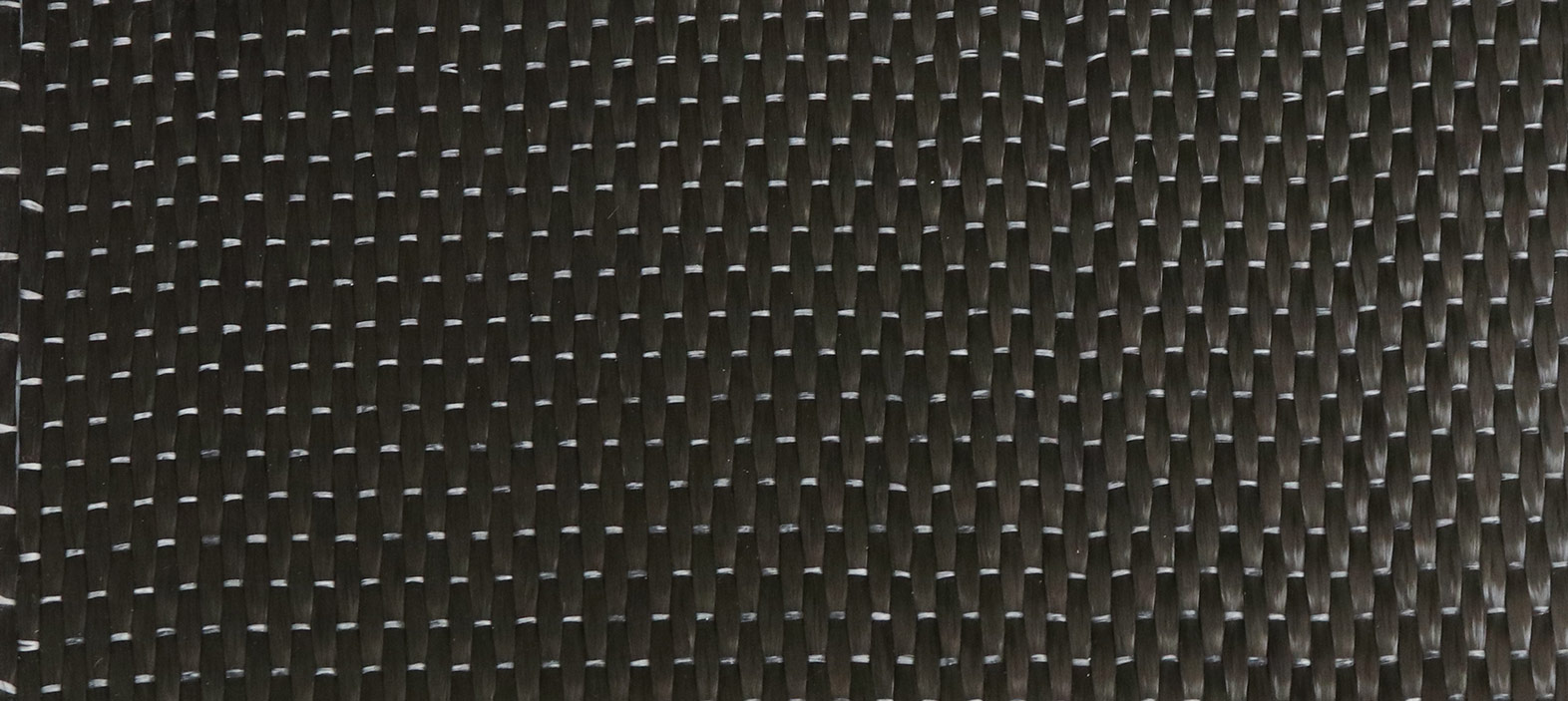

When most people think of carbon fiber, they think of woven carbon fiber. Woven carbon fiber is a fabric made up of thousands of interwoven fibers. This material has been used for decades in the aerospace, automotive and marine industries and is known for its strength and light weight.

Unidirectional carbon fiber is a newer material and is made up of fibers that are arranged in one direction. This gives the material a very high strength-to-weight ratio and makes it ideal for applications where weight is a major factor. Unidirectional carbon fiber is also more resistant to stretching and bending, making it a good choice for components that will be exposed to a lot of stress that is why people prefers buy carbon fiber sheets Unidirectional.

The major difference between the two materials is in their fiber orientation. Woven carbon fiber is made up of thousands of fibers that are woven together in various directions. This means that it is not as strong as unidirectional carbon fiber, which has all of its fibers aligned in the same direction. Unidirectional carbon fiber is also much more resistant to stretching and bending, making it a better choice for components that will be under a lot of stress.

Another difference between the two materials is their cost. Unidirectional carbon fiber is more expensive than woven carbon fiber due to the additional processes required to align the fibers in one direction. However, the higher cost of unidirectional carbon fiber is usually outweighed by its superior strength and durability.

When choosing between the two materials, you should consider how the component will be used and what properties are most important. If weight is a major factor or you want to buy carbon fiber rods, then unidirectional carbon fiber might be the better choice. If cost is a major factor, then woven carbon fiber could be the better choice. Understanding the differences between the two materials can help you make the right decision for your project.

Advantages of Unidirectional Carbon Fiber

1. Increased Strength: Unidirectional carbon fiber provides more strength in the direction of the fibers compared to woven fabrics, allowing for lighter weight components with greater strength.

2. Increased Stiffness: Unidirectional carbon fiber also has higher stiffness, or resistance to bending or deformation, than woven carbon fabric, allowing for a more precise control over the shape of the finished product.

3. Low Weight: Unidirectional carbon fiber is much lighter than steel, making it an ideal material for lightweight components.

4. High Temperature Resistance: Unidirectional carbon fiber has a high resistance to temperatures up to 350°C, making it suitable for components that must withstand high temperatures.

5. Chemical Resistance: Unidirectional carbon fiber is highly resistant to chemical attack, making it a good choice for components that must withstand strong corrosive chemicals.

6. Low Cost: Unidirectional carbon fiber is less expensive than other carbon fiber materials, making it a good choice for cost-sensitive applications.

Summing up

Unidirectional carbon fiber has a wide range of advantages, from its strength and durability to its lightweight and cost-effective nature. Its ability to be manipulated and customized to suit various needs and its resistance to corrosion makes it a great choice for many applications. It is also a great choice for those looking for a more environmentally friendly alternative to traditional materials. Its low coefficient of thermal expansion and its ability to resist fatigue make it an ideal material for many uses. With all of its advantages, unidirectional carbon fiber is an ideal choice for many applications.