Layering Techniques for Optimal Strength in Carbon Fiber Tube

👁 Reads: 1388

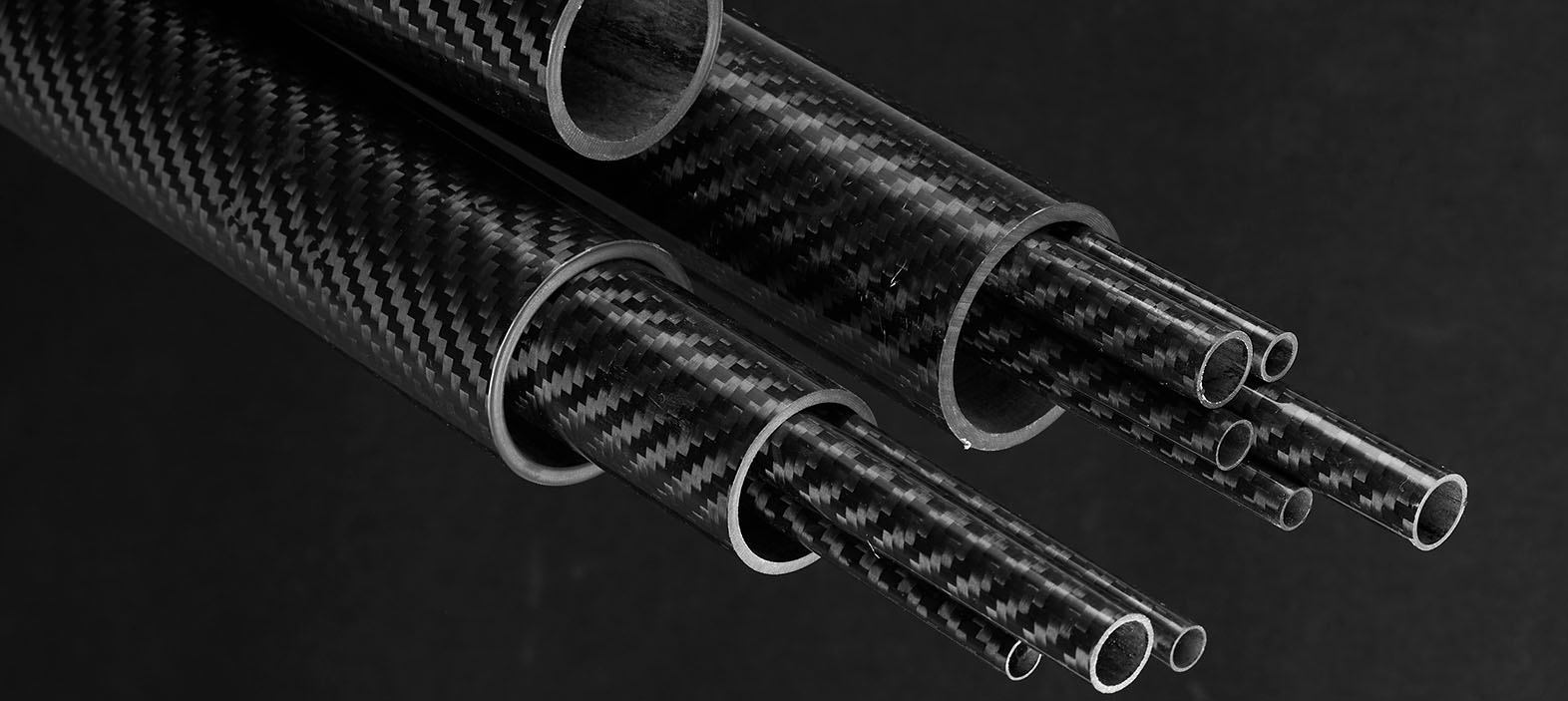

Carbon Fiber, known as the "black gold" of materials science, its unmatched strength, remarkable flexibility, and lightweight nature have revolutionized many industries. Carbon fiber tubes are incredibly versatile and robust, making them outstanding examples of engineering and design among their many uses. We’ll go on a fascinating journey through the layering techniques used in carbon fiber tube designs in this blog, revealing the trade secrets that enable designers and engineers to achieve the best possible strength and flexibility specifically suited for their projects.

Breaking the Secret of Carbon Fiber

Peeling back the layers of the carbon fiber mystery is the first step towards genuinely appreciating the mastery of layering techniques. Carbon fiber is primarily made up of minuscule carbon threads arranged in a crystal lattice. This configuration creates a material naturally resistant to corrosion, solid, and incredibly light. Carbon fiber transforms into a composite material that is well-known for its remarkable mechanical qualities when it is mixed with a polymer resin.

Layering Methods

Layering techniques are where the trance of carbon fiber happens. The features of the finished product are greatly influenced by the orientation, kind, and quantity of layers used. It's a union of science and art where creativity and skill are combined.

Fiber Alignment

In the mechanical characteristics of the finished product, a crucial factor is how the carbon fibers are arranged within the layers. The fiber placement angle has a significant effect on the strength and flexibility of the tube. Unidirectional fibers oriented parallel to the tube's length typically offer the highest strength. Nevertheless, introducing woven or braided patterns can add a controlled amount of flexibility, allowing the tube to twist or bend as needed.

Layer Categories

Carbon fiber tubes frequently combine different layer types to achieve the ideal balance of strength and flexibility. These layers are commonly classified as woven, unidirectional, and hybrid. The strongest layers are unidirectional ones, made up of fibers oriented in a single direction. Contrarily, crisscrossing fibers found in woven layers add greater flexibility. By combining woven and unidirectional patterns, hybrid layers enable engineers to customize the tube's properties for particular uses.

Count of Layers

The number of layers within it directly influences a carbon fiber tube's overall thickness and strength. Engineers can reinforce the tube and make it stronger and more rigid by adding more layers. On the other hand, if we use fewer layers, the resulting tube will be thinner and more flexible, which makes it perfect for applications where flexibility is crucial.

Resin Type

Choosing the right resin for carbon fiber tubes is critical for maximum strength and flexibility. Because of their remarkable mechanical properties, low shrinkage during curing, and excellent adhesion to carbon fibers, epoxy resins are the most widely used option. However, depending on the demands of the particular project, other resin types like polyester and vinylester can be used. Choosing the appropriate resin is essential to the design process because it can introduce variations in the tube's characteristics.

Harmonizing Sturdiness and Adaptability

The ultimate goal of layering techniques in carbon fiber tube designs is to attain a balanced strength-to-flexibility ratio that is specific to the needs of each project. Carbon fiber tubes, for example, are used in the aerospace industry and must adapt to the dynamic conditions of flight while withstanding high stresses and strains. Finding the ideal balance can yield significant weight savings, increasing performance and fuel efficiency.

Future Prospects for Designing Carbon Fiber Tubing

The field of carbon fiber tube design is constantly developing along with carbon fiber technology. Advancements like 3D printing, automated layup procedures, and the integration of nanomaterials are expanding the possibilities for carbon fiber applications. These developments offer more strength, adaptability, and economy in carbon fiber tube design and production.

Carbon fiber tube designs incorporating layering techniques are an artistic endeavor where science and creativity coexist, and the particular requirements of each project are skillfully and precisely fulfilled. It is imperative to become proficient in these methods since carbon fiber engineers and designers are constantly pushing the limits of what is possible with this material. We may create carbon fiber tubes with the best strength and flexibility, precisely suited to the demands of today's varied applications, by comprehending the interaction of fiber orientation, layer types, and layer count.